Radiator with chip heating function

A heat sink and chip technology, which is applied in the direction of electric solid-state devices, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of low difficulty in production and processing, unstable startup performance of chips at low temperature, etc., and achieve low production and processing difficulty and solve The low-temperature start-up performance is extremely unstable, which is conducive to the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

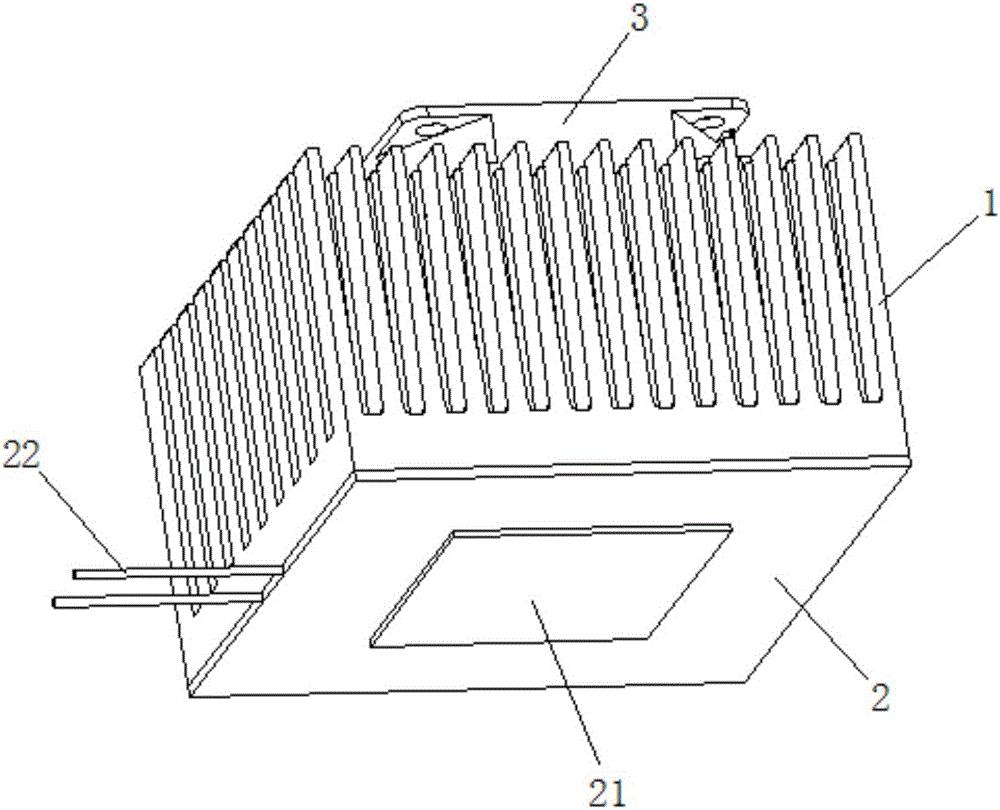

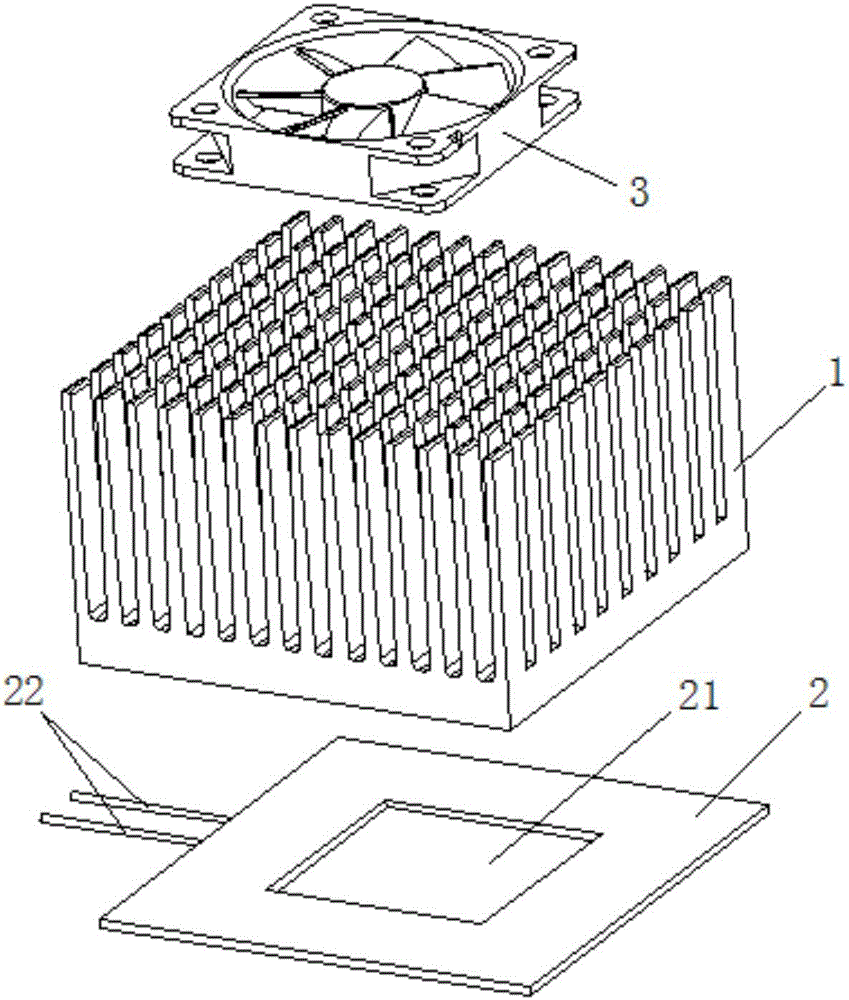

[0022] Such as Figure 1 to Figure 3 As shown in , Embodiment 1 of the present invention provides a heat sink with a chip heating function, including a heat sink body 1 and a chip pre-heating unit 2, and the chip pre-heating unit 2 is installed and fixed on the heat sink body 1 and the chip Contact the bottom surface of the connection. Wherein, the chip preheating unit 2 can be a heating film, on which there is an avoidance hole 21 for chip embedding, and the shape and size of the avoidance hole 21 match the chip; the specific structure can be: the chip preheating Unit 2 is square (also can be other shapes, such as circle), and described avoidance hole 21 is arranged on the center of chip preheating unit 2, and whole chip preheating unit 2 is annular; Described chip preheating unit 2 adopts The way of pasting (such as pasting with double-sided tape) is fixed on the bottom surface of the radiator body 1 .

[0023] In addition, the power line 22 of the chip preheating unit 2 c...

Embodiment 2 3

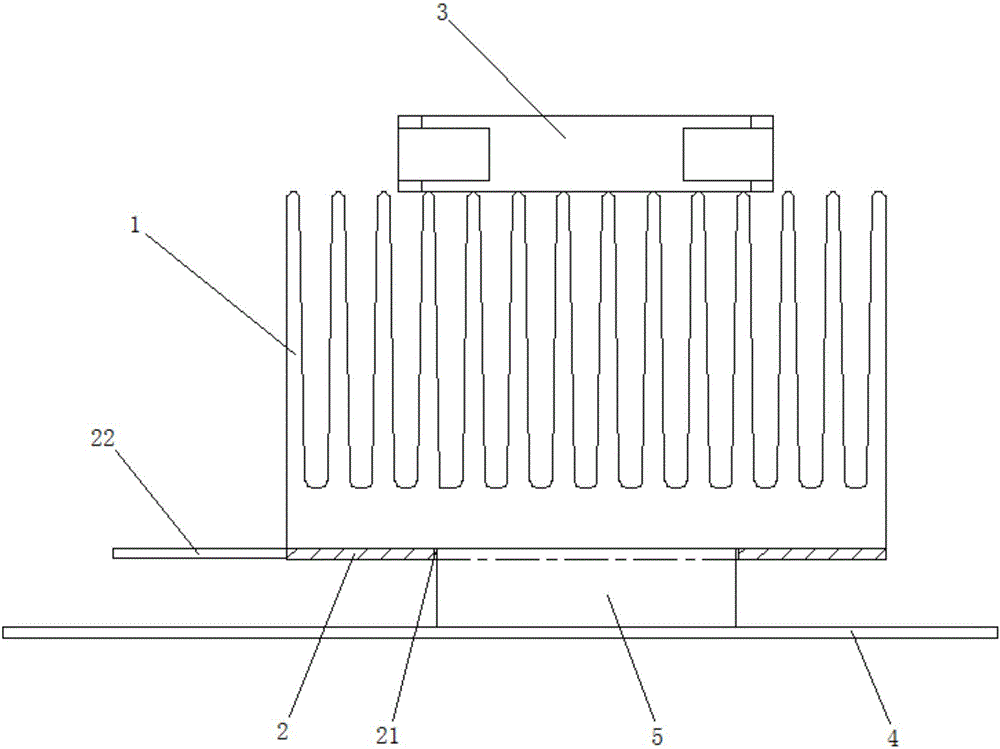

[0026] Such as Figure 4 with 5 As shown in , Embodiments 2 and 3 of the present invention provide a heat sink with a chip heating function, including a heat sink body 1 and a chip preheating unit 2, and the chip preheating unit 2 is installed and fixed on the heat sink body 1 The bottom surface of the contact connection with the chip. Wherein, the chip pre-heating unit 2 may be a heating film, on which there is an avoidance hole 21 for chip embedding, and the shape and size of the avoidance hole 21 match the chip. The only difference is that the escape hole 21 is an avoidance notch connected with the edge of the chip preheating unit 2 and is in the shape of a concave frame.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com