Hydraulic control one-way valve with pressure monitoring function

A hydraulically controlled one-way valve and pressure monitoring technology, which is applied in mining equipment, earth square drilling, mine roof supports, etc., can solve problems such as inability to analyze and use supports, inability to display pressure values in real time, maintenance and replacement, etc. It achieves the effect of compact structure, convenient downhole maintenance, and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described again below in conjunction with example and accompanying drawing thereof.

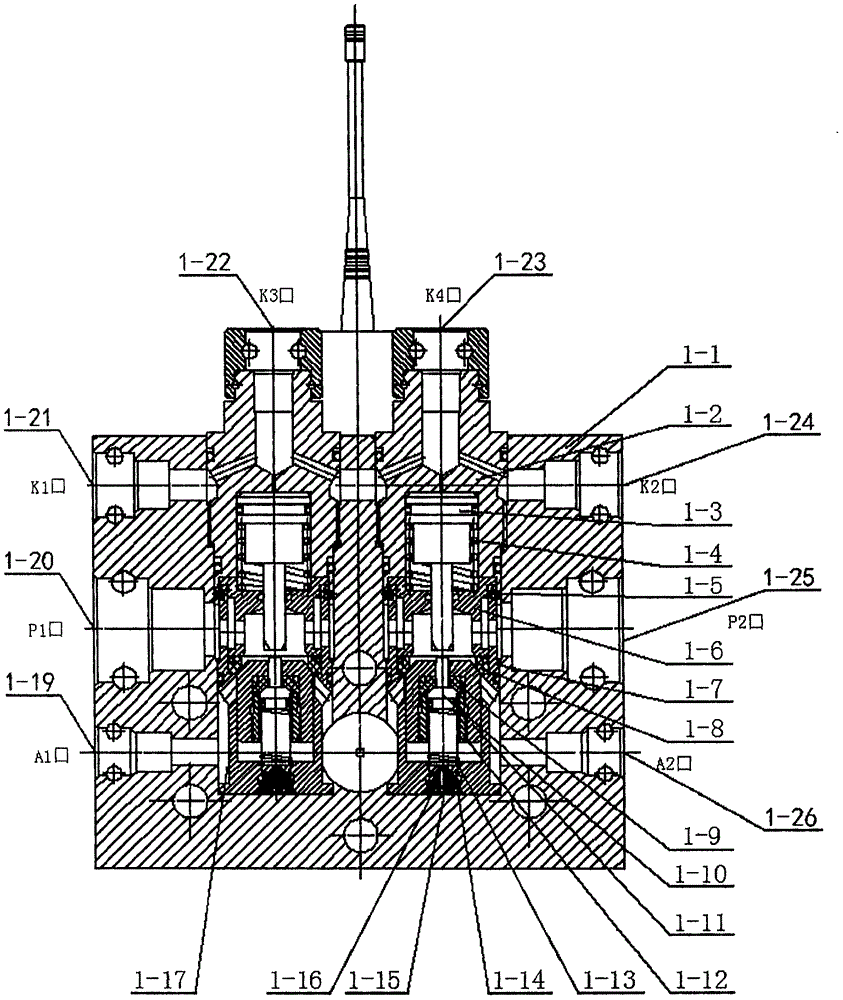

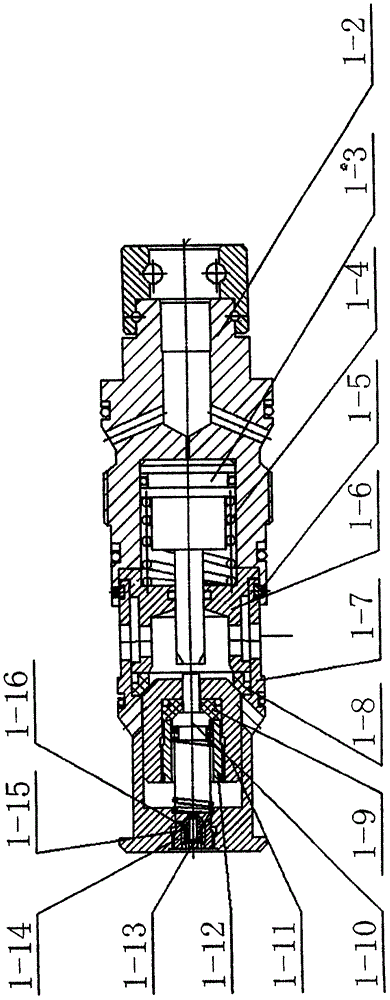

[0020] see Figure 1-Figure 5 , a hydraulically controlled one-way valve with pressure monitoring function, which includes a hydraulically controlled one-way valve body 1, a hydraulically controlled one-way valve body 1, a liquid-passing plate 2, and a mining intrinsically safe digital pressure gauge 3 through connecting bolts 4 Connected together, the hydraulic control check valve body 1 leads to the mine intrinsically safe digital pressure gauge 3 through the liquid hole 2-1 on the liquid plate 2, and the mine intrinsically safe digital pressure gauge 3 is formed by the pressure gauge valve body 3 -9, circuit board 3-2, sensor 3-12, LED display board 3-14, networking module 3-16, antenna 3-17 are formed, and pressure gauge valve body 3-9 is provided with on the liquid-passing plate 2 The pressure measuring port 3-18 connected with the liquid passage hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com