Wine made of wild strawberry, angelica sinensis and radix astragali and production process of wine

A technology of wild strawberry and preparation process, applied in the field of edible products, can solve the problem that functional ingredients cannot be absorbed and utilized, and achieve the effect of low alcohol content and sugar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

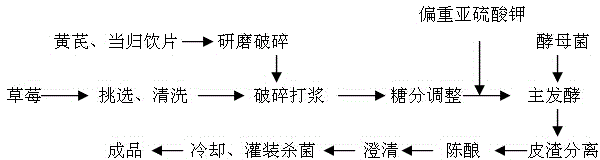

Method used

Image

Examples

Embodiment example 1

[0034] 1. Raw material pretreatment

[0035] Crush wild fresh strawberries with high maturity and no damage with a crusher to obtain 1000L strawberry pulp.

[0036] Weigh 6.7kg of astragalus decoction pieces and 3.3kg of angelica decoction pieces and crush them to 40 mesh respectively, and add them to the strawberry pulp.

[0037] 2. Adjustment of sugar content in feed liquid

[0038] When the sugar content of wild strawberry fruit is 4%, 200kg of white sugar must be added.

[0039] 3. Sterilization of feed liquid

[0040] Add potassium metabisulfite 180g in feed liquid.

[0041] 4. Yeast broth preparation

[0042] Add 200g of active dry yeast to 2000ml of warm water (38°C) containing 5% sugar, mix well and then place it in a water bath for cultivation, stirring once every 10min, and the activation time is 20min.

[0043] 5. Main fermentation

[0044] Inoculate the above-mentioned activated yeast liquid into the processed feed liquid, mix thoroughly, then pack into steri...

Embodiment example 2

[0052] 1. Raw material pretreatment

[0053] The wild fresh strawberries with high maturity and no damage are crushed with a crusher to obtain 1000L strawberry pulp.

[0054] Weigh 6.7kg of astragalus decoction pieces and 3.3kg of angelica decoction pieces and crush them to 60 mesh respectively, and add them to the strawberry pulp.

[0055]2. Adjustment of sugar content in feed liquid

[0056] When the sugar content of wild strawberry fruit is 7%, 170kg of white sugar must be added.

[0057] 3. Sterilization of feed liquid

[0058] Add potassium metabisulfite 270g in feed liquid.

[0059] 4. Yeast broth preparation

[0060] Add 200g of active dry yeast to 2000ml of warm water (38°C) containing 5% sugar, mix well and place it in a water bath for cultivation, stirring once every 10min, and the activation time is 30min.

[0061] 5. Main fermentation

[0062] Inoculate the above-mentioned activated yeast liquid into the processed feed liquid, mix thoroughly, then pack into s...

Embodiment example 3

[0070] 1. Raw material pretreatment

[0071] The wild fresh strawberries with high maturity and no damage are crushed with a crusher to obtain 1000L strawberry pulp.

[0072] Weigh 6.7kg of astragalus decoction pieces and 3.3kg of angelica decoction pieces and crush them to 50 mesh respectively, and add them to the strawberry pulp.

[0073] 2. Adjustment of sugar content in feed liquid

[0074] When the sugar content of wild strawberry fruit is 5.5%, 185kg of white sugar must be added.

[0075] 3. Sterilization of feed liquid

[0076] Add potassium metabisulfite 200g in feed liquid.

[0077] 4. Yeast broth preparation

[0078] Add 200g of active dry yeast to 2000ml of warm water (38°C) containing 5% sugar, mix well and then place it in a water bath for cultivation, stirring once every 10min, and the activation time is 25min.

[0079] 5. Main fermentation

[0080] Inoculate the yeast activation liquid into the processed feed liquid, mix thoroughly, then pack into aseptic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com