Feeding flavor for improving bamboo pulp sheet quality and application

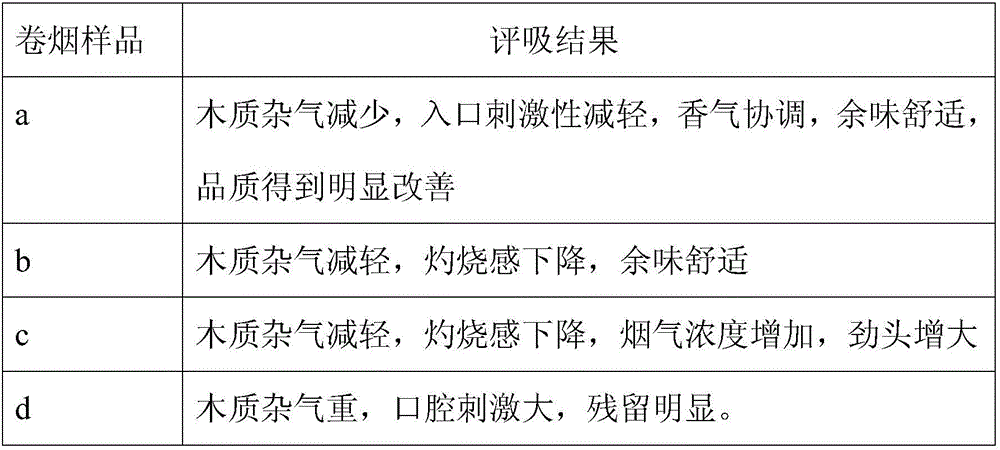

A technology for adding flavors and flakes, which can be used in applications, essential oils/flavors, and fat production. It can solve the problems of heavy wood odor, high irritation, and heavy residues.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

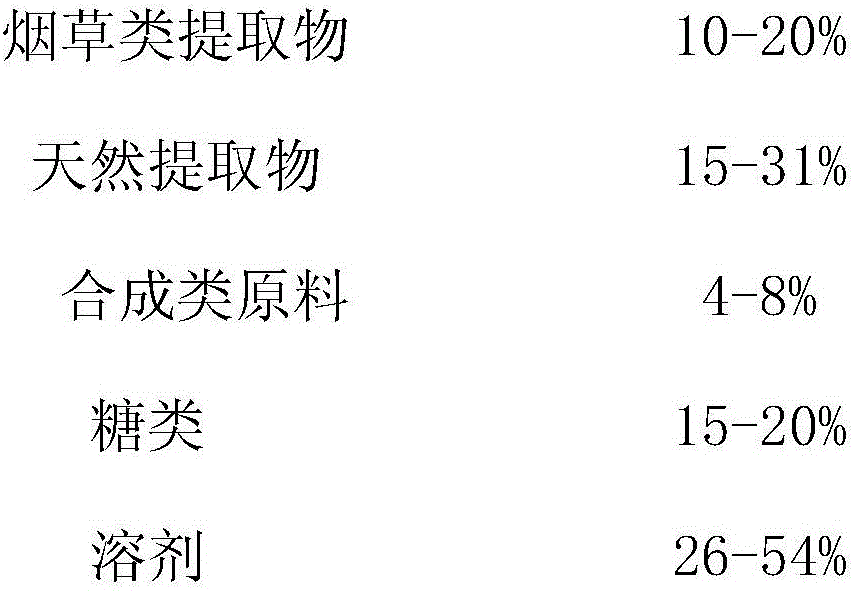

Method used

Image

Examples

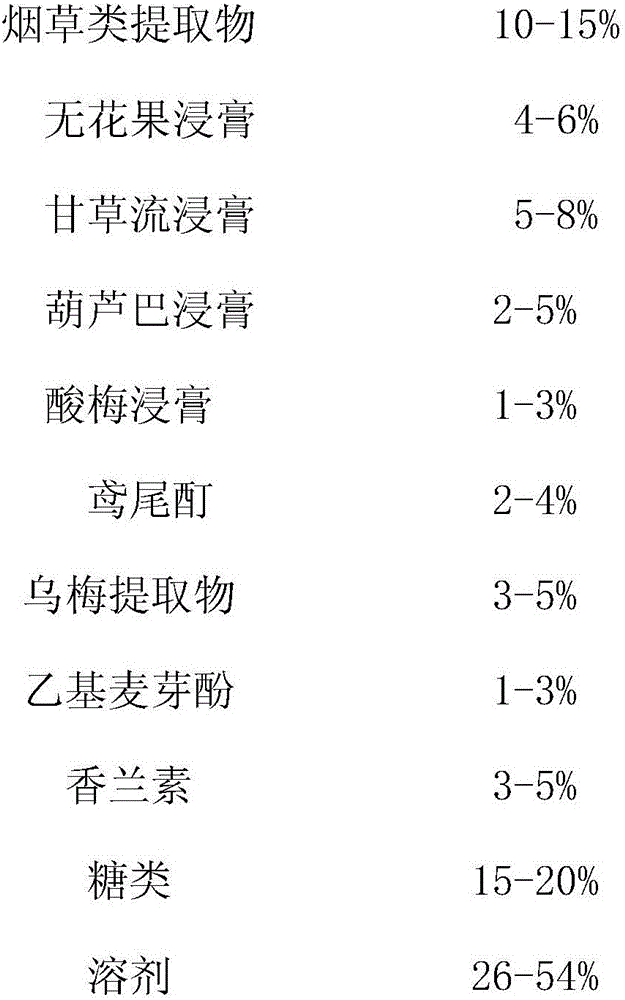

Embodiment 1

[0022] Embodiment 1, a kind of flavoring essence that improves the quality of bamboo pulp flakes, is prepared by mixing the following substances in mass percentage: 10% Yunyan extract, 4% fig extract, 5% licorice liquid extract, 2% fenugreek extract, 1% sour plum extract, 2% iris tincture, 3% ebony extract, 1% ethyl maltol, 3% vanillin, 20% fructose, 30 % water, 19% propylene glycol.

Embodiment 2

[0023] Embodiment 2: a kind of flavoring essence that improves the quality of bamboo pulp sheet, is formulated after the material mixing by following mass percent: 12% Zimbabwean tobacco leaf extract, 5% fig fruit extract, 6% licorice liquid extract , 4% fenugreek extract, 2% sour plum extract, 3% iris tincture, 4% ebony extract, 2% ethyl maltol, 4% vanillin, 16% glucose, 21% Water, 21% propylene glycol.

Embodiment 3

[0024] Embodiment 3: a kind of flavoring essence that improves the quality of bamboo pulp flakes is prepared by mixing the following substances in mass percentage: 15% Yunyan extract, 8% fig extract, 4% licorice liquid extract, 7% fenugreek extract, 5% sour plum extract, 3% ethyl maltol, 5% vanillin, 10% fructose, 7% glucose, 30% water, 6% propylene glycol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com