Self-adhered air protection adhesive tape for automobile component and preparation method of self-adhered air protection adhesive tape

A technology for spare parts and gas protection, which is applied in the field of self-adhesive gas protection tape for auto parts and its preparation, can solve the problems of print marks and surface pollution of spare parts, and achieves the effects of suitable peeling strength, low cost and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

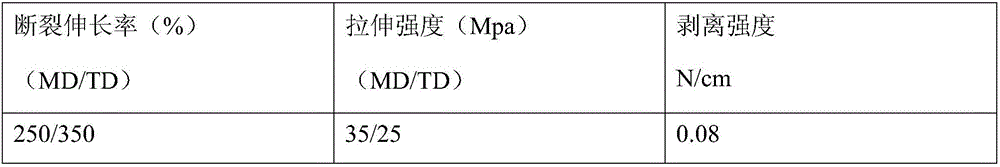

Embodiment 1

[0030] Substrate layer raw material: polypropylene. The density is 0.90g / cm 3 , the melting point is 167°C, and the melt index MI is 0.5g / 10min.

[0031] Intermediate layer raw material: ethylene-alpha olefin copolymer B with a density of 0.918g / cm 3 , the melt index MI is 0.2g / 10min, and the melting point is 121°C.

[0032] Adhesive layer raw material: ethylene-vinyl acetate copolymer with a VA content of 5% and a density of 0.935g / cm 3 , the melt index MI is 3g / 10min, and the melting point is 60°C; the density of ethylene-α-olefin copolymer A is 0.870g / cm 3 , the melt index MI is 1g / 10min, and the melting point is 40°C. The ethylene-α-olefin copolymer A content was 40%.

[0033]Antioxidant: 0.1% of the total mass of the middle layer, diphenylamine and didodecyl alcohol ester at a mass ratio of 4:1.

[0034] Light stabilizer: 0.2% of the total mass of the middle layer, phenyl o-hydroxybenzoate.

[0035] Preparation methods include:

[0036] The raw materials of the ad...

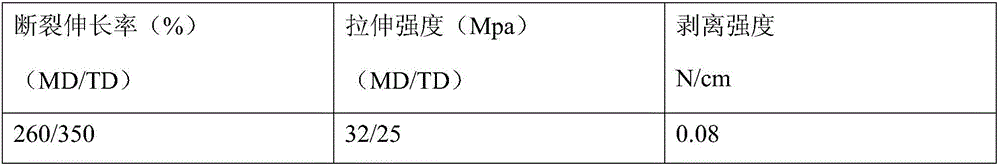

Embodiment 2

[0039] Substrate layer raw material: polypropylene. The density is 0.91g / cm 3 , the melting point is 168°C, and the melt index MI is 1g / 10min.

[0040] Intermediate layer raw material: ethylene-alpha olefin copolymer B with a density of 0.925g / cm 3 , the melt index MI is 1.0g / 10min, and the melting point is 124°C.

[0041] Adhesive layer raw material: ethylene-vinyl acetate copolymer with VA content of 20%, density of 0.942g / cm 3 , the melt index MI is 15g / 10min, and the melting point is 70°C; the density of ethylene-α-olefin copolymer A is 0.893g / cm 3 , the melt index MI is 6g / 10min, and the melting point is 50°C. The content of ethylene-alpha olefin copolymer A is 50%.

[0042] Antioxidant: 0.5% of the total mass of the middle layer, p-phenylenediamine and trioctyl in a mass ratio of 2:1.

[0043] Light stabilizer: 0.5% of the total mass of the middle layer, tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite.

[0044] Preparation methods include:

[0045] The raw mater...

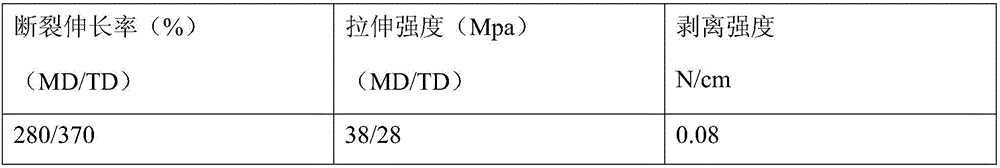

Embodiment 3

[0048] Substrate layer raw material: polypropylene. The density is 0.90g / cm 3 , the melting point is 170°C, and the melt index MI is 2g / 10min.

[0049] Middle layer raw material: ethylene-alpha olefin copolymer B with a density of 0.935g / cm 3 , the melt index MI is 1.9g / 10min, and the melting point is 127°C.

[0050] Adhesive layer raw material: ethylene-vinyl acetate copolymer with a VA content of 45% and a density of 0.947g / cm 3 , the melt index MI is 30g / 10min, and the melting point is 87°C; the density of ethylene-α-olefin copolymer A is 0.915g / cm 3 , the melt index MI is 10g / 10min, and the melting point is 60°C. The ethylene-α-olefin copolymer A content was 60%.

[0051] Antioxidant: 0.3% of the total mass of the middle layer, 2,6-di-tert-butyl-4-methylphenol and diester of thiodipropionate in a mass ratio of 3:1.

[0052] Light stabilizer: 1% of the total mass of the middle layer, 2-(2-hydroxy-3,5-di-tert-phenyl)-5-chlorinated benzotriazole.

[0053] Preparation m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com