Titanium-polymerized polyester-modified organic silicon high-temperature-resistant paint

A high-temperature-resistant coating and polyester modification technology, which is applied in the direction of fire-proof coatings, coatings, etc., can solve the problems of general MEK resistance, short service life of coatings, high curing temperature, etc., achieve good physical and mechanical properties, and prolong service life , Improve the effect of curing crosslinking degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

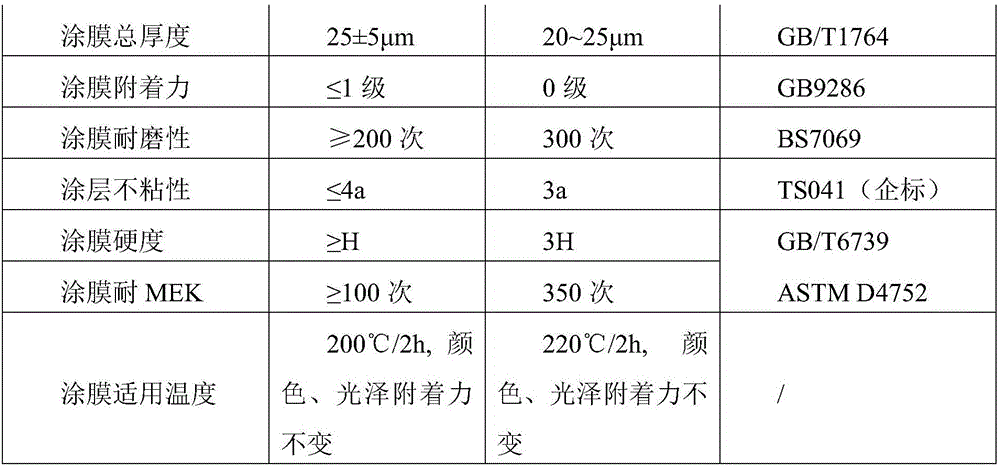

Embodiment 1

[0026] (1) Mix 50 parts of polyester modified silicone resin (solid content of silicone resin is more than 50%, silicon content of 35-45%) with 5 parts of xylene, 5 parts of butyl acetate, 10 parts of propylene glycol methyl ether acetate 10 parts of titanium dioxide, 1 part of carbon black, 5 parts of micron-grade alumina, 15 parts of micron-grade barium sulfate and stir evenly at high speed, and then grind with a sand machine to a fineness of ≤15 microns;

[0027] (2) Add 0.5 part of titanium polymer, 0.5 part of leveling agent modified silicone oil, 2 parts of anti-adhesive additive phenyl alkyl silicone with low polymerization degree, and 1 part of 10-60 μm white bead powder in sequence, stir well, and then Viscosity was adjusted to 60 sec / DIN 4 cup, 23°C using solvent.

Embodiment 2

[0029] (1) Stir 40 parts of polyester modified silicone resin (solid content of silicone resin is more than 50%, silicon content of 15-20%) and 10 parts of propylene glycol methyl ether acetate, and then add 0.5 part of carbon black, Mix 5 parts of micron-grade alumina at high speed, and then grind it with a sand machine to a fineness of ≤15 microns;

[0030] (2) Add 0.1 part of titanium polymer, 0.5 part of leveling agent modified silicone oil, 1 part of anti-adhesive additive phenyl alkyl silicone with low degree of polymerization, and 0.1 part of 30-90 μm silver powder in sequence, stir evenly, and use The solvent adjusts the viscosity to 50 sec / DIN 4 cup at 23°C.

Embodiment 3

[0032] (1) Mix 60 parts of polyester modified silicone resin (solid content of silicone resin is more than 50%, silicon content of 65-75%) with 10 parts of xylene, 10 parts of propylene glycol methyl ether acetate, 10 parts of propylene glycol methyl ether Stir evenly in one part, then add 5 parts of iron red, 10 parts of iron yellow, 15 parts of micron-grade barium sulfate, and 10 parts of micron-grade silicon carbide, stir evenly at high speed, and then grind it with a sand machine to a fineness of ≤15 microns;

[0033] (2) Add 2 parts of titanium polymer, 2 parts of leveling agent modified silicone oil, 3 parts of anti-adhesive additive phenyl alkyl silicone with low degree of polymerization, and 5 parts of 120-200 μm copper-colored bead powder in sequence and stir evenly. Finally, use a solvent to adjust the viscosity to 70 seconds / DIN4 cup, 23°C.

[0034] The titanium polymer used in Examples 1-3 is Tytan PBT from Taiwan borica company Co., Ltd, and the titanium content i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com