Preparation method of novel ion-type vinyl acetate emulsion for high saline-alkali land desertification management

The technology of vinyl acetate and saline-alkali land is applied in the field of preparation of novel ionic vinyl acetate emulsion, which can solve the problems of easy powdering of sand-fixing materials and poor consolidation strength, and achieve the effects of low price, inhibition of evaporation and wide sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

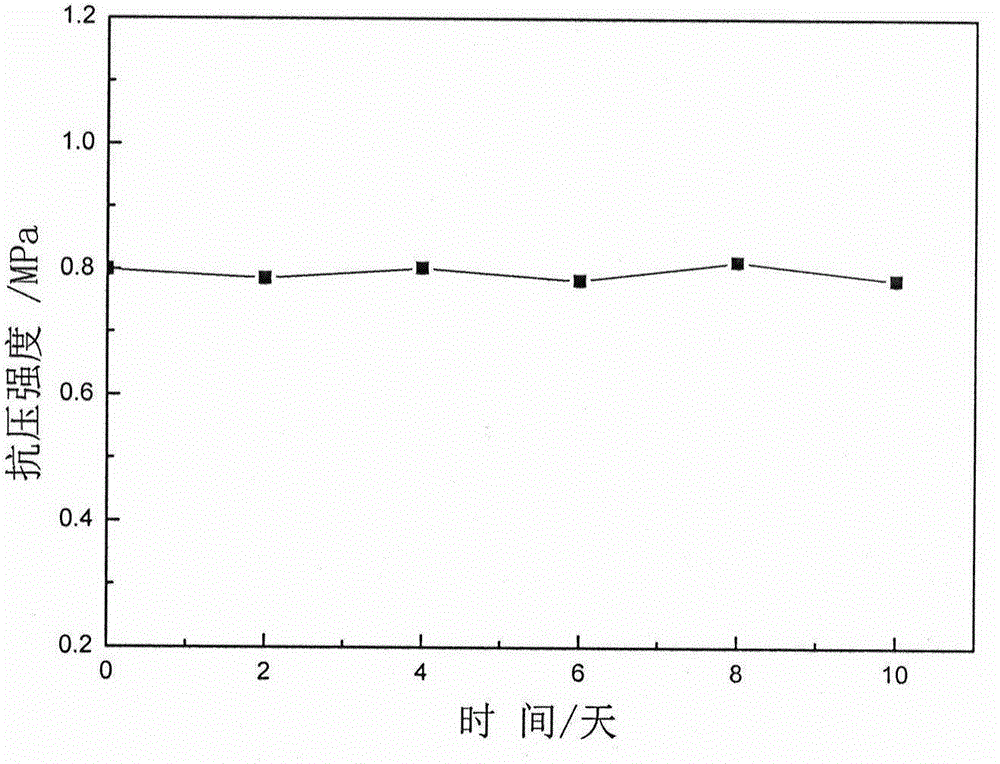

Image

Examples

Embodiment 1

[0032] 32.5 parts of vinyl acetate, 1.0 part of acrylic acid and 16.5 parts of dibutyl maleate monomers were premixed to obtain mixed monomers. Dissolve 0.3 parts of potassium persulfate in 30 parts of deionized water and 1.2 parts of sodium styrene sulfonate in 30 parts of water. Add 60 parts of water, 0.67 parts of sodium lauryl sulfate and 1.5 parts of L35 into the reaction kettle, heat up to 50°C, react for 15 minutes, continue to heat up to 65°C, add 1 / 3 (accounted for total potassium persulfate Weight fraction) Potassium persulfate solution, emulsified for 20 minutes, then heated to 74 ° C, added 1 / 3 (mass fraction of the total weight of the mixed monomer) vinyl acetate, acrylic acid and dibutyl maleate mixed monomer and 1 / 3 (mass fraction of the total weight of sodium styrene sulfonate) sodium styrene sulfonate aqueous solution, after reacting for 30 minutes, slowly add the remaining initiator dropwise with a constant pressure dropping funnel, and slowly add the remaini...

Embodiment 2

[0041] 30 parts of vinyl acetate, 2 parts of acrylic acid and 15 parts of dibutyl maleate monomers were premixed to obtain mixed monomers. 1.0 parts of potassium persulfate was dissolved in 15 parts of deionized water, and 2.0 parts of 2-acrylamido-2-methylpropanesulfonic acid was dissolved in 20 parts of water. Add 70 parts of water, 1.0 parts of sodium lauryl sulfate and 2.0 parts of Tween 60 into the reaction kettle, heat up to 55°C, react for 30 minutes, continue to heat up to 65°C, add 1 / 3 of the persulfuric acid The mass fraction of the total weight of potassium) potassium persulfate solution, emulsified for 30 minutes, then warmed up to 75 ° C, and added 1 / 5 (the mass fraction of the total weight of the mixed monomer) of vinyl acetate and dibutyl maleate mixed monomer and 1 / 3 (mass fraction of the total weight of 2-acrylamido-2-methylpropanesulfonic acid) 2-acrylamido-2-methylpropanesulfonic acid aqueous solution, initiate the reaction for 10min, and use constant pressu...

Embodiment 3

[0043] 50 parts of vinyl acetate, 1.5 parts of acrylic acid and 10 parts of dibutyl maleate monomers are premixed to obtain mixed monomers. Dissolve 1.5 parts of potassium persulfate in 20 parts of deionized water and 2.0 parts of sodium p-vinylsulfonate in 20 parts of water. Add 30 parts of water, 1.0 part of sodium oleate and 2.0 parts of polyether L35 into the reaction kettle, heat up to 55°C, react for 20 minutes, continue to heat up to 65°C, add 1 / 4 of the total weight of potassium persulfate mass fraction) potassium persulfate solution, emulsified for 30 minutes, then heated up to 75°C, added 1 / 4 (the mass fraction of the total weight of the mixed monomer) the mixed monomer of vinyl acetate and dibutyl maleate and 1 / 5 (accounting for the mass fraction of the total weight of sodium p-vinylsulfonate) sodium vinylsulfonate aqueous solution, initiated the reaction for 10 minutes, slowly added the remaining initiator dropwise with a constant pressure dropping funnel, and slow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com