Method and equipment for treating ammonia-nitrogen wastewater

A treatment method and wastewater treatment technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of poor versatility, poor treatment effect, narrow application range, etc., to achieve Ease of expansion, stable continuous operation, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

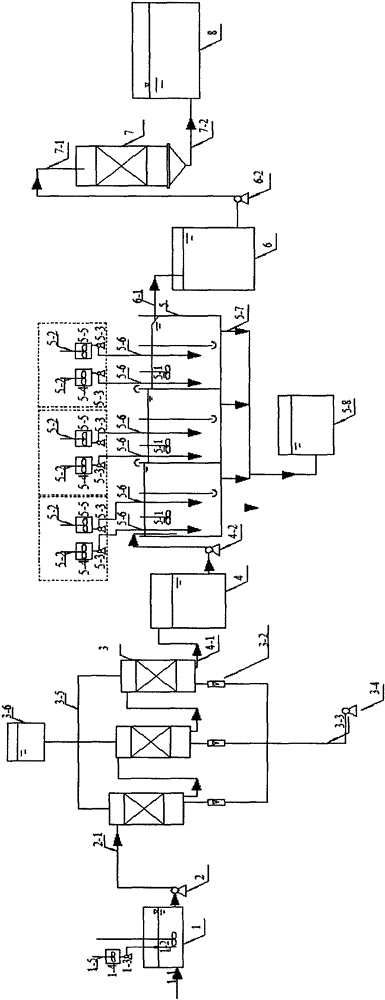

[0034] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] 1) pH adjustment stage: the waste water enters the adjustment tank (1) through the water inlet pipe (1-1) and is mixed with sodium hydroxide solution to adjust the pH value to between 10 and 11;

[0036] 2) Blow-off stage: send the waste water with adjusted pH value into the blow-off tower (3), air enters from the bottom of the blow-off tower (3), and carry out three-stage blow-off successively to the waste water, and the blow-off tower (3) The tail gas is collected into the tail gas treatment device (3-6) through the tail gas collection pipeline (3-5);

[0037] 3) struvite precipitation reaction stage: the waste water after the above blow-off treatment is sent into the struvite precipitation reactor (5), and magnesium chloride and disodium hydrogen phosphate are added to form magnesium ammonium phosphate precipitation with the ammonia nitrogen in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com