Double synchronizing clutch and planetary gear coupling double-motor power system

A planetary gear train and power system technology, which is applied to the arrangement of multiple different prime movers of power devices, pneumatic power devices, and general power devices, can solve the problem of insufficient starting ability on slopes, large application limitations, and system volume. Large and other problems, to achieve the effect of improving the loadability of the vehicle, reducing the driving torque requirements, and adapting to a wide range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

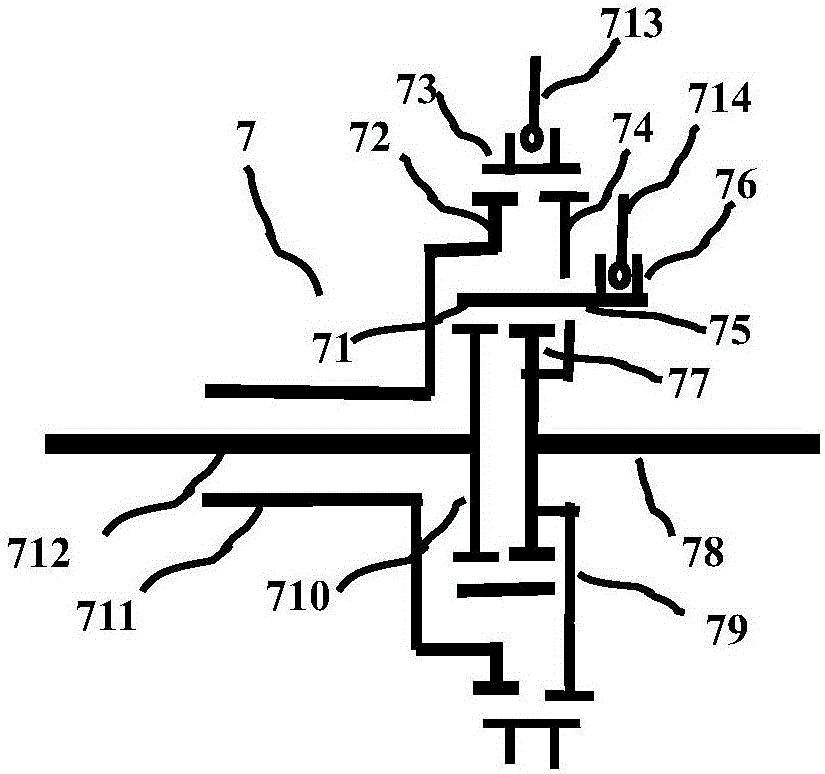

[0036] Such as figure 1 As shown, a kind of double synchronous clutch 7 (embodiment one) of the present invention comprises two sets of synchronizers (inner synchronizer and outer synchronizer) arranged radially inside and outside, the first spline hub 74 of the outer synchronizer, the inner synchronizer The second splined hub 77 of the synchronizer is mechanically connected to a splined hub 79 of an integrated structure. The splined hub 79 is provided with a channel 75, and the coupling sleeve 71 of the inner synchronizer is provided with an axial protrusion and passes through the splined hub 79. Passage 75 on the keyboard hub 79 is connected with the shift ring groove 76 of the inner synchronizer, the operating mechanism 714 of the inner synchronizer is flexibly connected with the shift ring groove 76 of the inner synchronizer, and the operating mechanism 713 of the outer synchronizer is connected with the outer synchronizer. The joint sleeve 73 of the synchronizer is movabl...

Embodiment 2

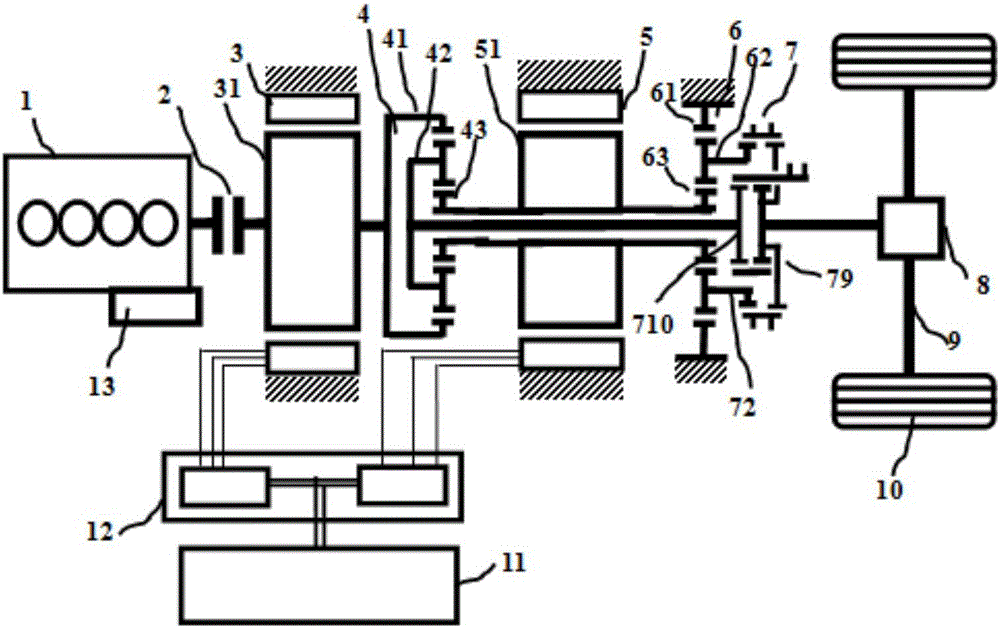

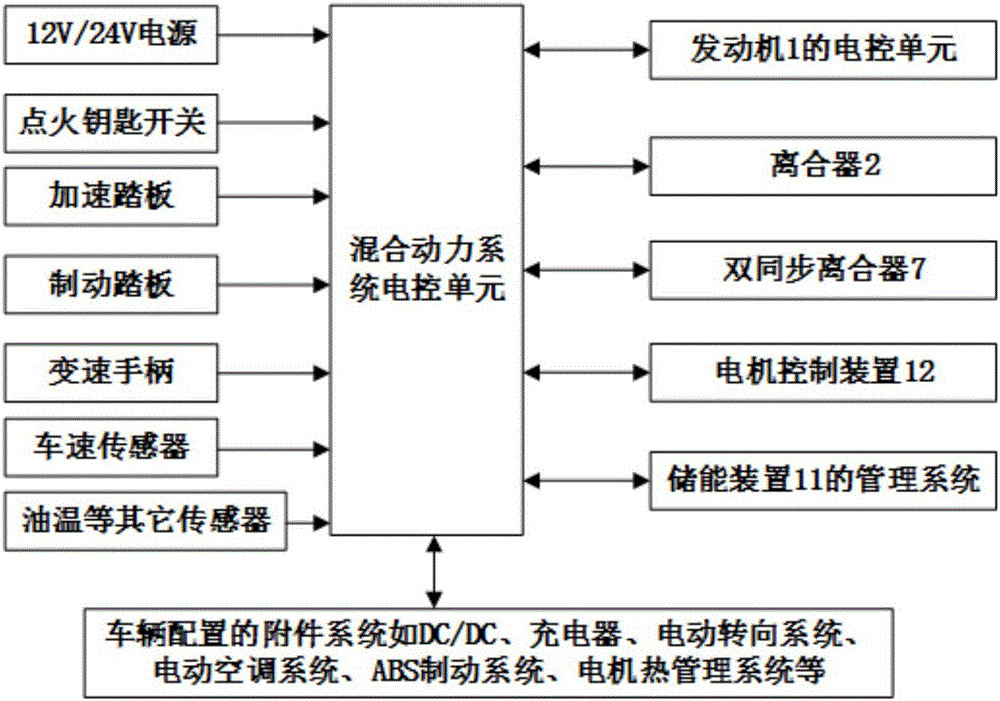

[0045] Such as figure 2 shown, and see figure 1 , the present invention's four-mode planetary gear coupled continuously variable speed hybrid system (embodiment 2) includes: engine 1, clutch 2, first motor 3, first planetary gear train 4, second motor 5, second planet Gear train 6, the double synchronous clutch 7 described in Embodiment 1, the reduction differential 8, the energy storage device 11 and the motor control device 12, wherein the first planetary gear train includes a first ring gear, a first planet carrier, The first sun gear, the second planetary gear train includes the second ring gear, the second planet carrier, the second sun gear, the output end of the crankshaft of the engine 1 is connected with the input end of the clutch 2, and the first rotor of the first motor 3 31 are respectively connected with the output end of the clutch 2 and the first ring gear 41 of the first planetary gear train 4, and the second rotor 51 of the second motor 5 is respectively co...

Embodiment 3

[0059] Such as Image 6 As shown, the five-mode planetary gear coupled continuously variable speed hybrid system in the third embodiment is basically the same as the second embodiment, the difference is that the five-mode planetary gear coupled continuously variable speed hybrid system in the third embodiment In order to further realize the direct drive mode of the engine 1, the type hybrid drive system also includes a brake lock device 14, which is used to brake and lock the sun gear 43 of the first planetary gear train 4 For the control of unlocking, one end of the brake locking device 14 is connected to the sun gear 43 of the planetary gear train 4 , and the other end is connected to the housing. The electric control unit of the hybrid power system set in the third embodiment, on the basis of the electric control unit of the hybrid power system described in the second embodiment, adds the hardware circuit, coordinated control, fault diagnosis, etc. of the brake lock device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com