Flow mixer integrating post-mixing injection and self-oscillation

A self-excited oscillation and ejection technology, which is applied in the abrasive feeding device, explosion generating device, abrasive and other directions, can solve the problem of poor pressure transformation characteristics and cavitation, long erosion time of the transport pipe wall, and jet flow along the way Large loss and other problems, to avoid the accumulation of abrasives, easy processing, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with accompanying drawing:

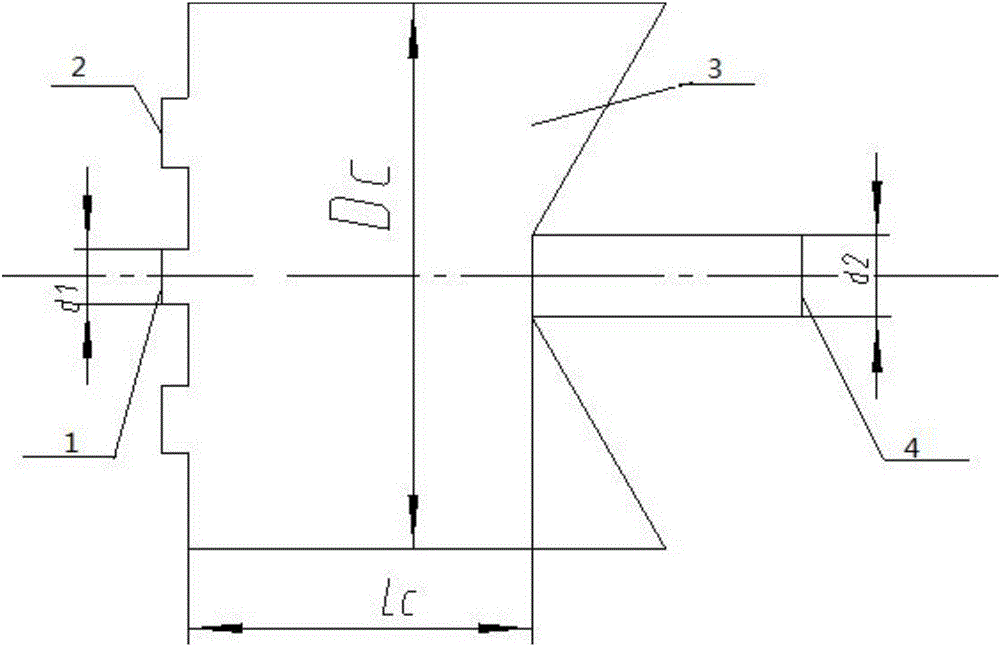

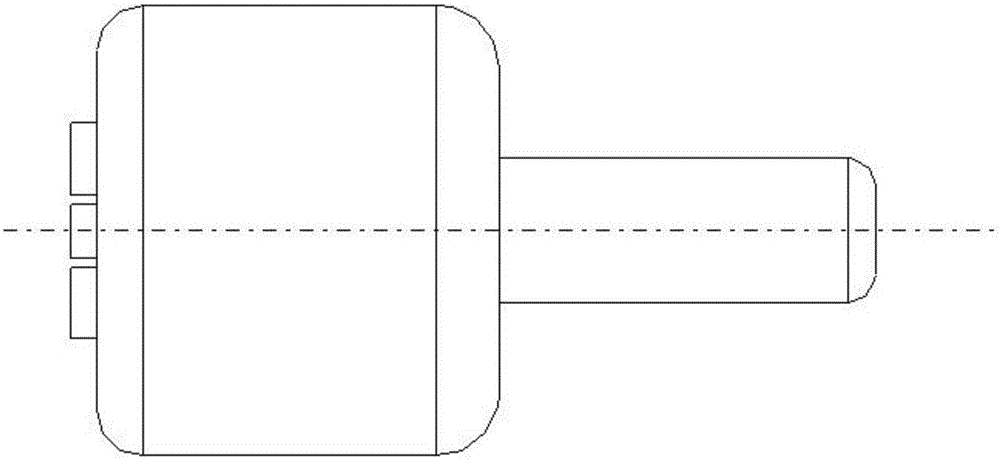

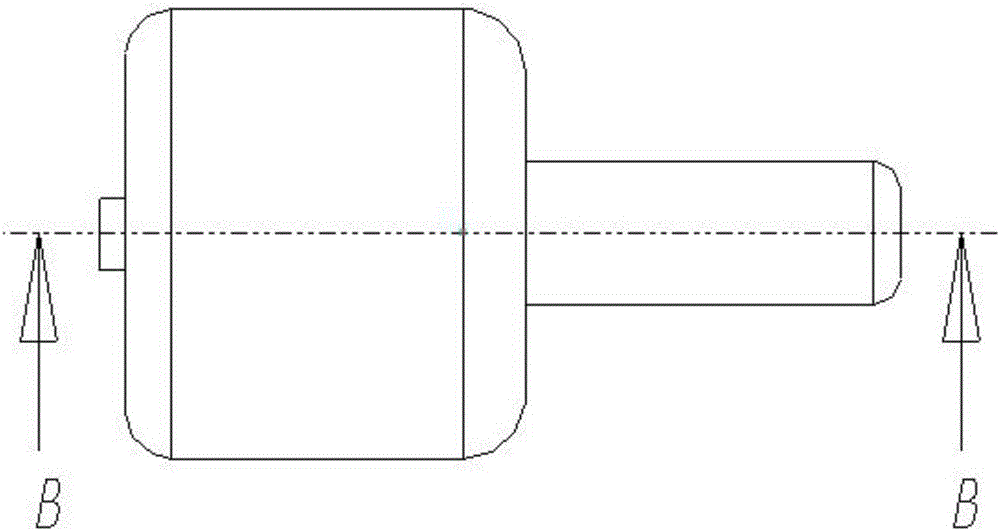

[0033] Such as figure 1 As shown, a flow mixer integrating post-mixing and self-excited oscillation pulses has a structure including a high-pressure water nozzle 1 , an abrasive inlet 2 , a mixing oscillation chamber 3 and a mixing nozzle 4 . The invention adopts the post-mix ejector mixing principle and the self-excited oscillation principle. First inject high-pressure water into the mixing and oscillating chamber 3 of the mixer through the high-pressure water nozzle 1, and use the post-mixing injection mixing principle to suck the abrasive from the abrasive inlet 2 into the mixing and oscillating chamber 3, and then use the principle of self-excited oscillation to pump the abrasive into the mixing and oscillating chamber 3. The high-pressure water and the abrasive are mixed and accelerated in the mixing and oscillating chamber, and then the abrasive jet is ejec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com