Paint layer vibration polishing protection clamp for vane fan-shaped assemblies

A technology for protecting fixtures and sectors, which is applied in the direction of manufacturing tools, grinding workpiece holders, and surface polishing machine tools. It can solve problems such as delaying production cycles, peeling off the paint layer on the edge of the intake and exhaust, and increasing production costs. Accelerate the flow rate, The effect of enhancing the gloss decoration and preventing scratches and bumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

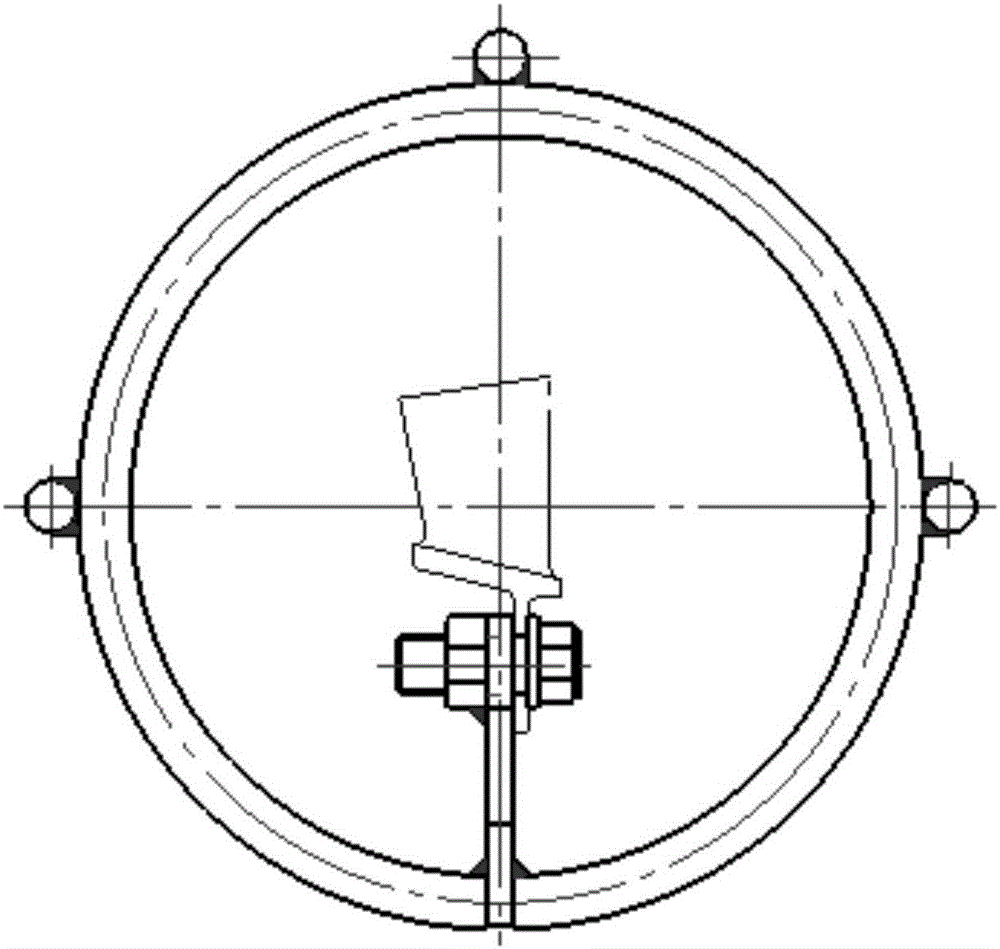

[0023] Such as figure 1 and figure 2 As shown, the blade fan-shaped assembly paint layer vibration light decoration protection fixture of the present invention includes a transverse installation rod 3, a plurality of transverse support rods 1 and a plurality of longitudinal rings 2; a plurality of longitudinal rings 2 are connected by a plurality of transverse support rods Together they form a cylindrical cage structure, and the transverse installation rods 3 used to fix the blade fan-shaped components are connected to a plurality of longitudinal rings 2, and the transverse installation rods 3 are located in the cage structure.

[0024] Further, it includes four longitudinal rings 2, three horizontal support rods 1 and one horizontal installation rod 3, and the three horizontal support rods 1 and one horizontal installation rod 3 are evenly ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com