Bottle cap transporting system

A conveying system and bottle cap technology, which is applied in the field of bottle cap manufacturing equipment, bottle cap and material packaging machinery, can solve the problems of high cap output efficiency, inconvenient use of caps, complex structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

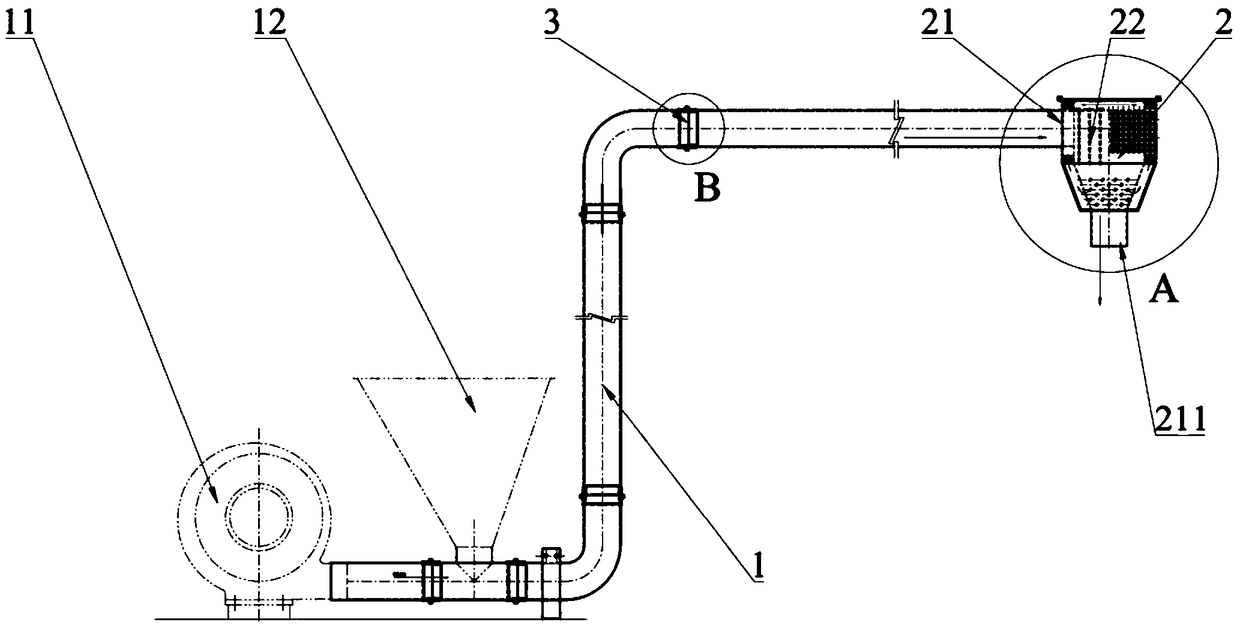

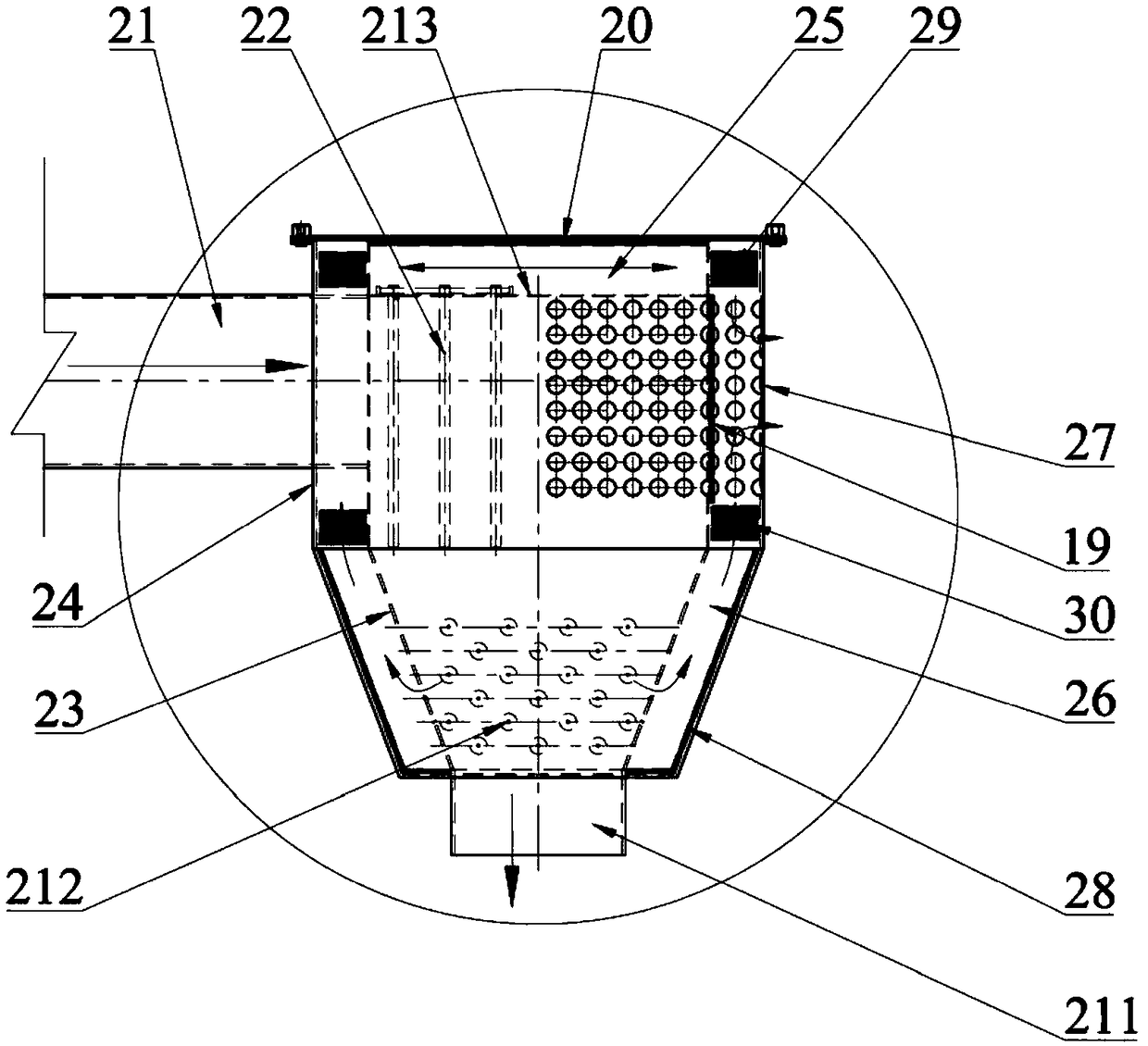

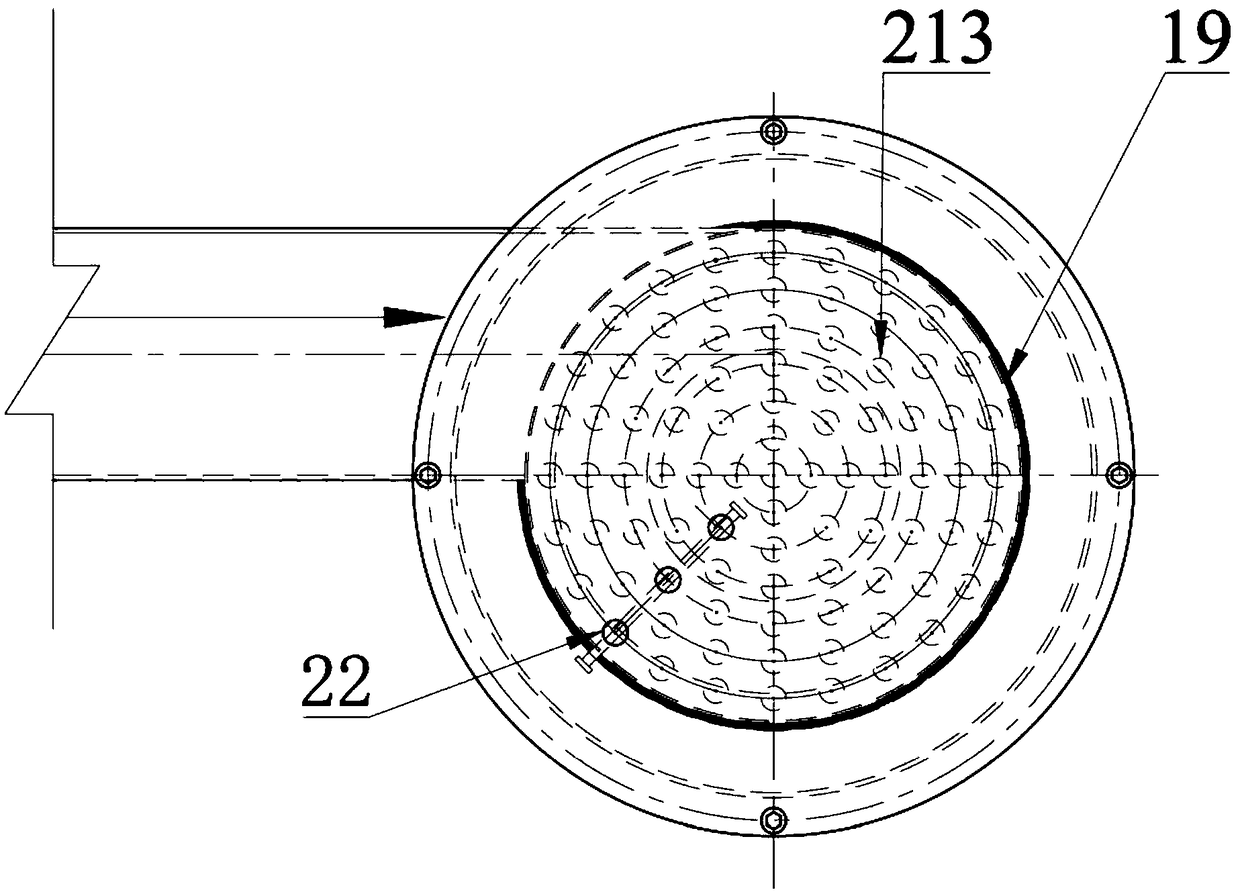

[0021] Such as figure 1 , 2 Embodiment 1 of the present invention shown is a bottle cap delivery system, comprising a delivery pipeline 1 and a pressure relief device 2; A bottle cap feeding port 12 is arranged on the top; the high-speed airflow and the bottle cap passing through the delivery pipeline 1 enter the interior of the pressure relief device 2 through the material inlet 21 on one side of the pressure relief device 2; enter the pressure relief device 2; The bottle cap of the device 2 rotates in a circular motion under the blowing of the high-speed airflow and hits the disturbing rod 22 inside the pressure relief device 2. The disturbing rod 22 swings with the air pressure to disturb the circular motion of the bottle cap. The bottle cap due to its own weight Free fall and discharge through material outlet 211.

[0022] Such as figure 2 , 3 As shown, there are several disturbance rods 22, and the disturbance rods 22 are metal rods hanging inside the pressure relief...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com