Wafer cleaning machine for physiotherapy instrument production

The technology of a physical therapy instrument and cleaning machine, which is applied in the field of wafer cleaning machines for the production of physical therapy instruments, can solve problems such as poor working effect of physical therapy instruments, affecting wafer effects, and scratches on the wafer surface, so as to prevent bumps and scratches. scratches, prevent force bumps, and reduce scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

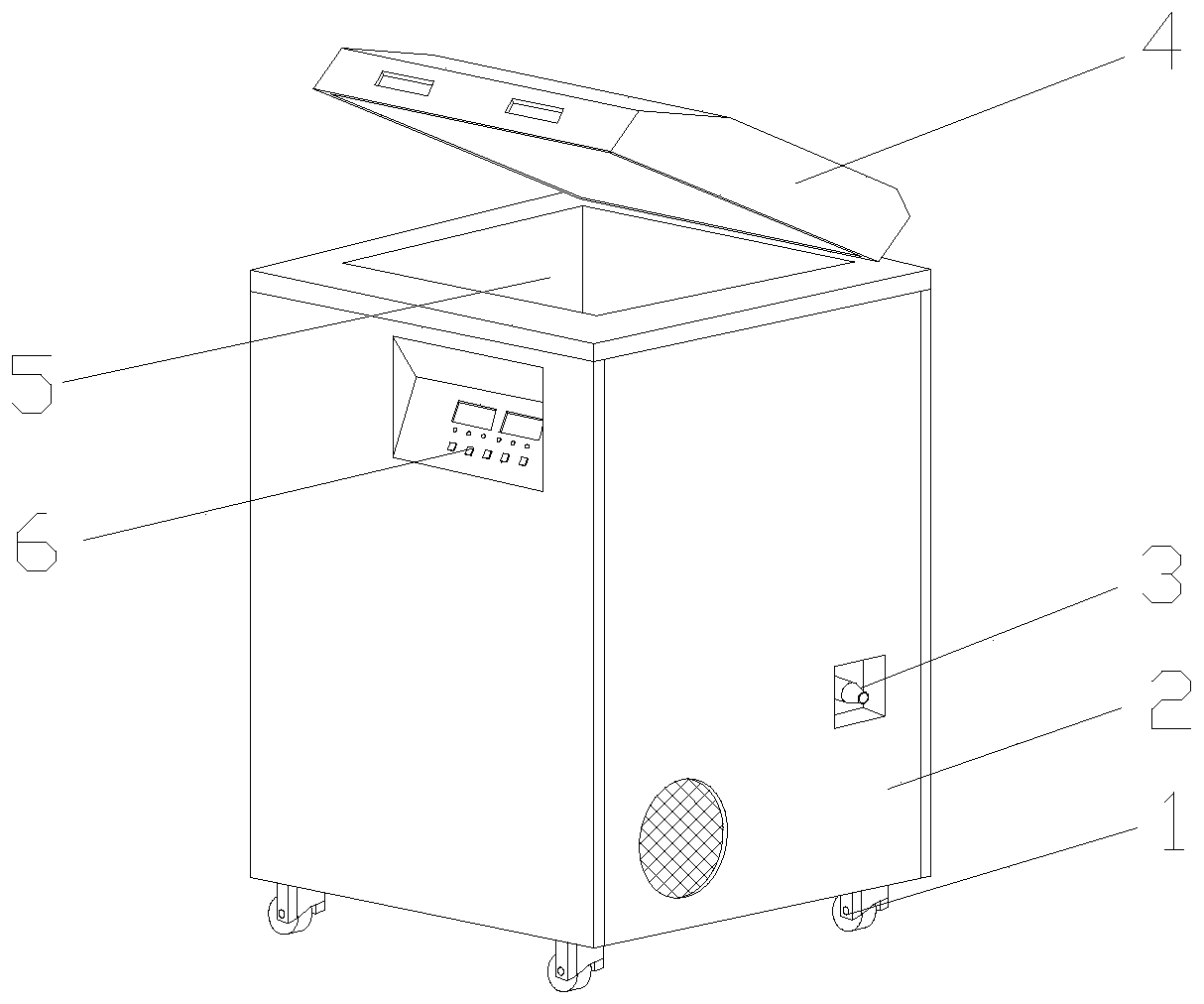

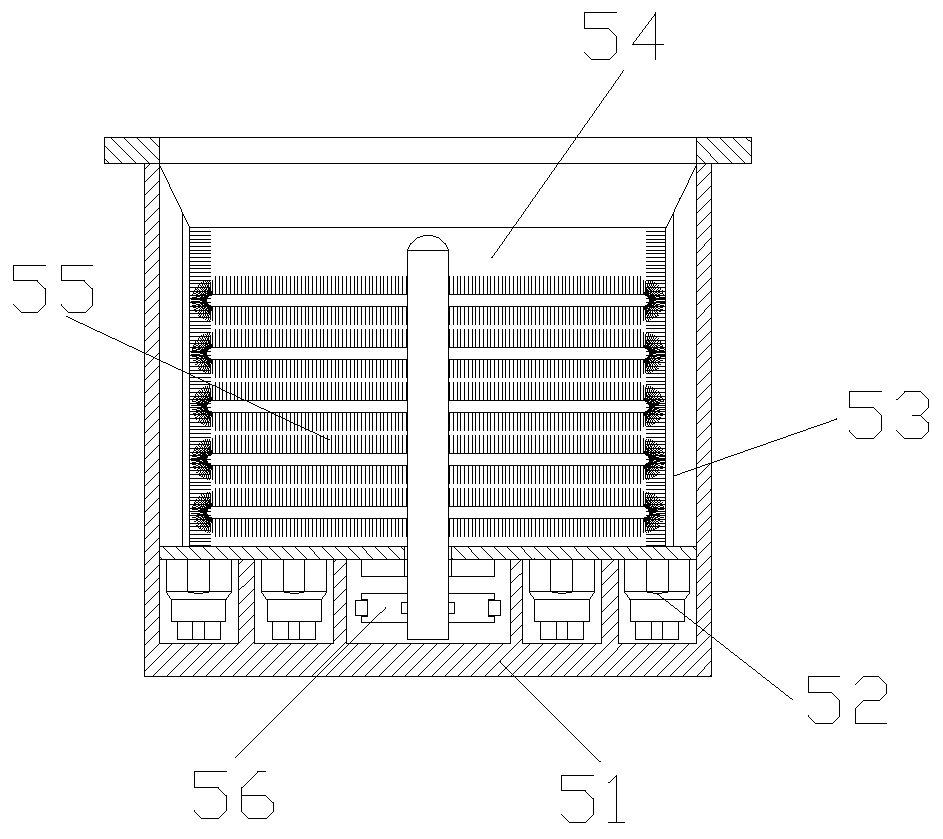

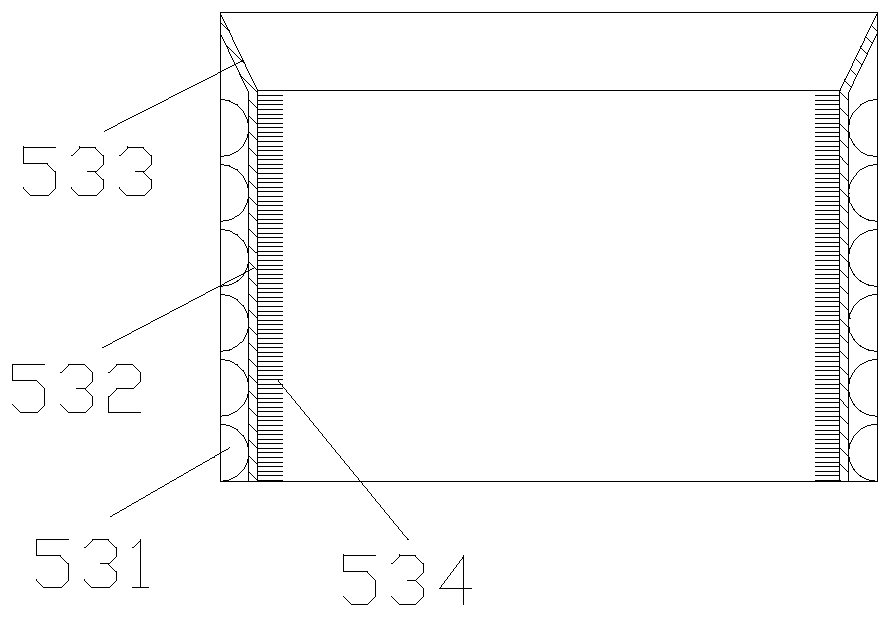

[0033] Its structure includes caster 1, cabinet 2, drain pipe 3, case cover 4, cleaning mechanism 5, control panel 6, and described caster 1 is installed on the lower end of cabinet 2 and adopts mechanical connection, and described drain pipe 3 is embedded in cabinet 2 inside and It communicates with the cleaning mechanism 5. The box cover 4 is installed horizontally on the upper end of the cabinet 2 and connected by hinges. The cleaning mechanism 5 is embedded and installed inside the cabinet 2. Electrically connected by wires; the cleaning mechanism 5 includes an outer box 51, an ultrasonic transducer 52, an inner edge protection structure 53, a cleaning chamber 54, an auxiliary cleaning structure 55, and a rotating wheel 56, and the ultrasonic transducer 52 is embedded and installed Inside the outer box 51, the inner edge protection structure 53 is emb...

Embodiment 2

[0038] Example 2: Please refer to Figure 1-Figure 2 , Figure 6-Figure 12 , the specific embodiments of the present invention are as follows:

[0039] Its structure includes caster 1, cabinet 2, drain pipe 3, case cover 4, cleaning mechanism 5, control panel 6, and described caster 1 is installed on the lower end of cabinet 2 and adopts mechanical connection, and described drain pipe 3 is embedded in cabinet 2 inside and It communicates with the cleaning mechanism 5. The box cover 4 is installed horizontally on the upper end of the cabinet 2 and connected by hinges. The cleaning mechanism 5 is embedded and installed inside the cabinet 2. Electrically connected by wires; the cleaning mechanism 5 includes an outer box 51, an ultrasonic transducer 52, an inner edge protection structure 53, a cleaning chamber 54, an auxiliary cleaning structure 55, and a rotating wheel 56, and the ultrasonic transducer 52 is embedded and installed Inside the outer box 51, the inner edge protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com