Novel floating positioning horizontal broaching plate for broaching machine

A positioning horizontal and new type of technology, applied in broaching machines, broaching devices, metal processing equipment, etc., can solve problems such as misalignment of center lines, and achieve practical, high-efficiency, and high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

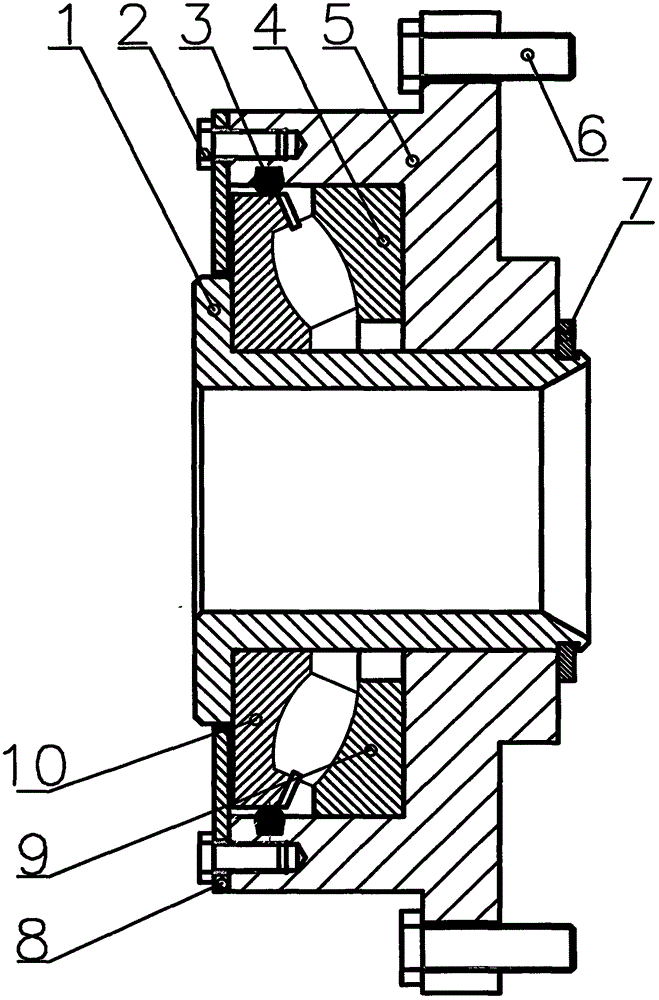

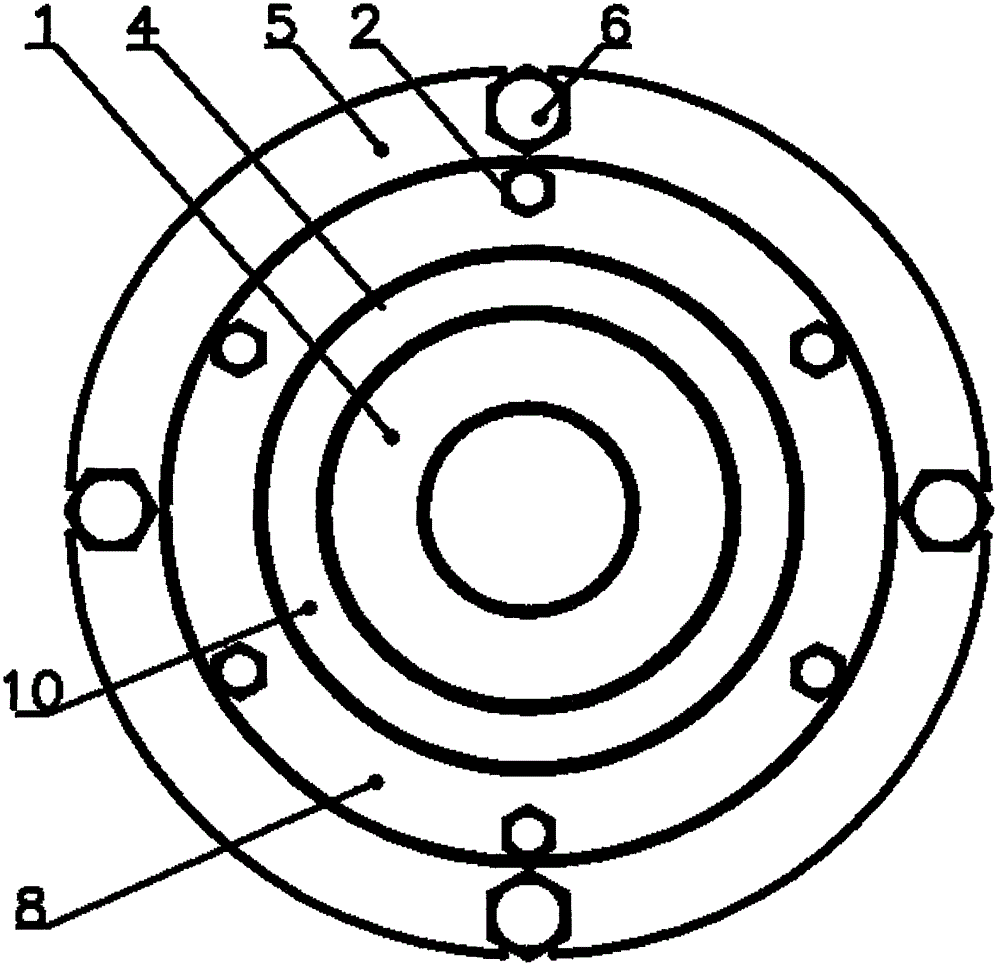

[0017] Such as figure 1 , figure 2 As shown, a new type of floating positioning horizontal broaching puller, when the present invention is assembled as a whole, firstly press the bearing seat ring 9 into the cavity of the bearing seat type puller 5 according to the small interference fit, so as to ensure The end surface of the bearing race 9 is firmly attached to the bottom surface of the cavity of the bearing seat puller 5, and then the journal of the quick-change bushing 1 is lightly pressed into the inner diameter of the bearing shaft ring 10 according to a small interference fit, so that the quick-change bushing The end face of the step of 1 is closely attached to the end face of the bearing shaft ring 10; install the O-shaped rubber ring 3 in the O-shaped sealing ring groove in the cavity of the bearing housing type pull plate 5, and install the bearing shaft ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com