Tool provided with cutting chip flow guiding capillaries and functions and machining method of tool

A capillary and tool technology, which is applied to tools for lathes, cutting inserts, metal processing equipment, etc., can solve the problems of cooling and lubricating fluid infiltration, cluttered capillaries, and poor control of width and depth, reducing cutting force and Effects of cutting heat, extended tool life, and improved workpiece quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

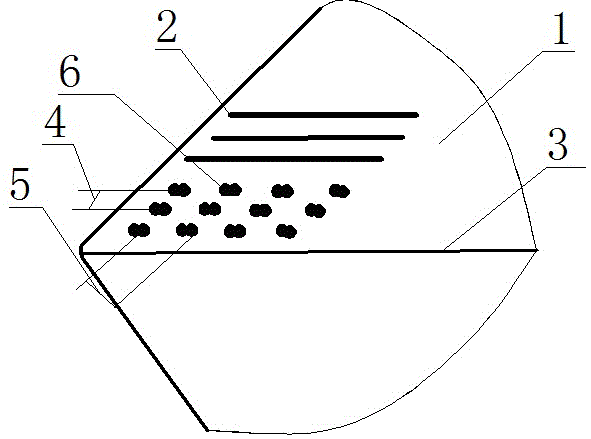

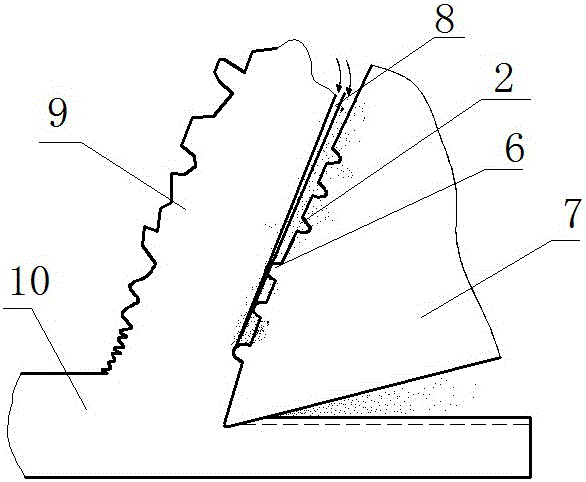

[0024] In this embodiment, the cutting tool is made of high-speed steel, the cutting material is aluminum alloy, and the cutting method is pouring.

[0025] In this embodiment, the diode-pumped YAG laser is the first choice. By laser processing the working surface of the high-speed steel tool material, the pouring cutting method is adopted. Since the feed rate of the pouring cutting method is relatively large, it is necessary to actively form a wider and deeper hole at the bottom of the chip. Capillary: Due to the cutting of soft aluminum alloy material, the size of the texture array can be completely copied to the bottom of the chip to form the best capillary.

[0026] The implementation of technical characterictic of the present invention comprises the following steps:

[0027] In step A, the surface of the tool is pretreated; the surface of the tool to be textured is polished so that the measured surface roughness Ra is less than 0.3 microns.

[0028] Step B: Carry out las...

Embodiment 2

[0036] In this embodiment, the cutter is a PCBN cutter, the cutting material is hard titanium alloy, and the cutting method is spraying.

[0037] Fiber laser is the first choice in this embodiment. By laser processing the working surface of PCBN tool material, due to the cutting of hard titanium alloy material, the size of the texture array cannot be completely copied at the bottom of the chips. It is necessary to control the arrangement and size of the texture array so that at the bottom of the chips Optimal capillary formation.

[0038] The implementation of technical characterictic of the present invention comprises the following steps:

[0039] In step A, the surface of the tool is pretreated; the surface of the tool to be textured is polished so that the measured surface roughness Ra is less than 0.3 microns.

[0040] Step B, laser processing is carried out on the working surface of the PCBN tool, and the asperity shape array is processed, which is 200 microns away from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com