Method for preparing supported bimetal organic framework material MIL-100(Fe-Cu) and denitration application

An organic framework and bimetal technology, applied in the field of preparation of new dual-core metal-organic framework material MIL-100, can solve the problems of high reaction temperature, narrow temperature window, vanadium toxicity, etc., and achieve high catalytic activity, regular pore structure, crystal uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: The preparation method of stable metal precursor solution.

[0031] Prepare 5mL, 0.7mol / LCuSO 4 ·5H 2 The O solution was dissolved in 60 mL of ultrapure water, and a mixed solution of CTAB, PVP, and citric acid (molar ratio 1:1:3) was added dropwise, and magnetically stirred for 10 min. 5mL, 1.2mol / L NaOH solution or 1.2mol / L NaBH 4The solution was dropped into the above solution at a constant speed. Ultrasonic treatment was carried out for 30 minutes while titrating, and after all the titration was completed, it was placed on a magnetic stirrer and stirred for 30 minutes.

Embodiment 2

[0032] Embodiment 2: the preparation method of MIL-100 (Fe) catalyst.

[0033] Ferric nitrate nonahydrate (3.35 mmol) and trimesic acid (3.35 mmol) were dissolved in 25 mL of ultrapure water. The uniformly mixed solution was placed in a closed glass container, and the mixed solution was heated by high-frequency electromagnetic wave oscillating microwaves. After a heating time of 25s, the temperature was increased to 160°C and maintained for 15 minutes, and a uniformly dispersed orange solid was obtained.

[0034] The product was treated in a water bath with high-purity water and absolute ethanol at 60°C (1 g of catalyst was added to about 150 mL of high-purity water or ethanol) to remove impurities. and dried in a constant temperature drying oven at 70°C. The dried samples were subjected to vacuum activation treatment to prepare catalysts.

Embodiment 3

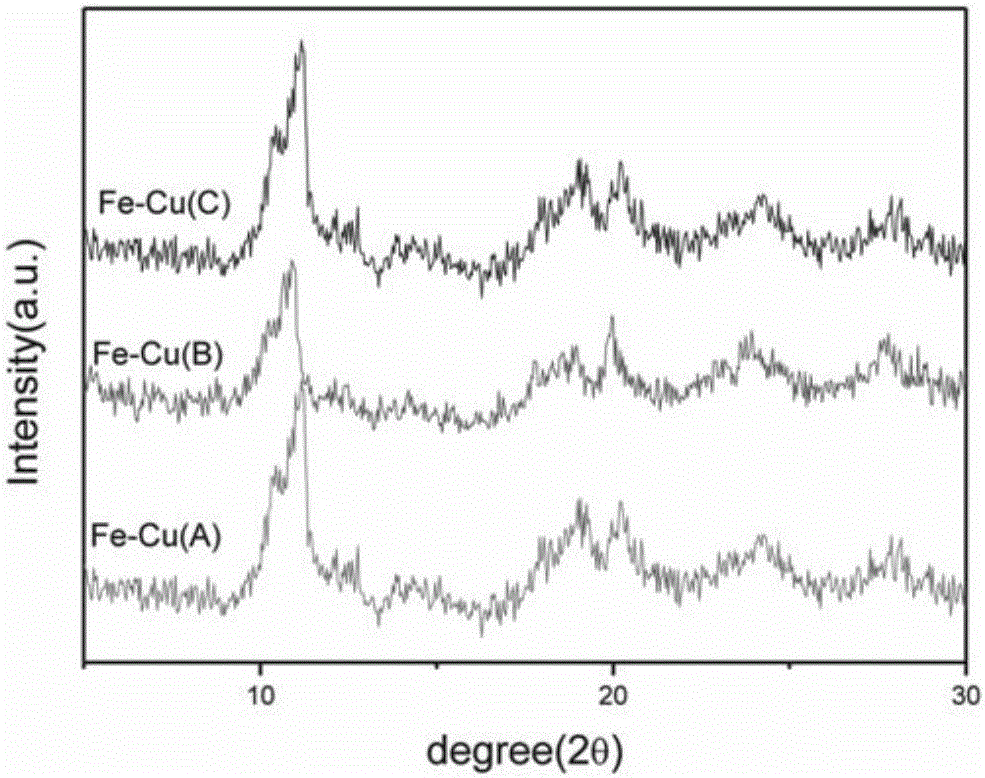

[0035] Embodiment 3: the preparation method of MIL-100 (Fe-Cu) catalyst.

[0036] Take 5mL, 10mL, and 15mL of the above-mentioned stable metal precursors, add 0.2g of Fe-MOF material, and stir magnetically for 2h. Then move the reactant to a polyvinyl chloride liner reactor, seal it and place it in an oven for heating at 100°C for 12h. After the reaction kettle is lowered to room temperature, the product is centrifuged for 3-5 times (the solution is high-purity water), soaked in absolute ethanol solution and washed repeatedly. Finally, the product was heated overnight in a constant temperature drying oven at 70° C. to obtain a pure brown yellow powder, namely the organic framework material MIL-100 (Fe—Cu), with a yield of 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com