Preparation method for conjugated oil, conjugated oil and application thereof

A kind of oil and conjugation technology, applied in the application, fatty acid production, fatty acid chemical modification and other directions, can solve the problems of increasing the viscosity of waste oil, increasing the peroxide value, deepening the color and so on, to achieve high conversion rate and less catalyst dosage , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

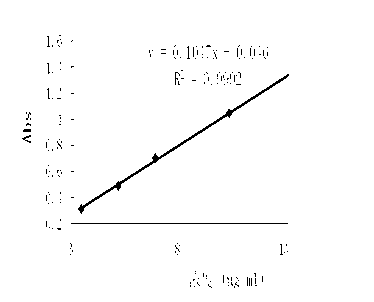

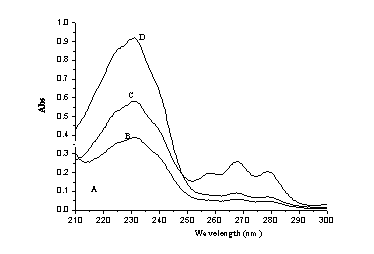

Embodiment 1

[0068] Weigh 100g of transgenic soybean oil (the mass fraction of linoleic acid as determined by gas chromatography is 50.88%, and the mass fraction of linolenic acid is 6.86%, purchased from COFCO Group) and 0.5g of elemental iodine are placed in a three-necked flask, heated and stirred, and passed through immediately. Inject high-purity nitrogen, reflux at 180°C for 3 hours, and then turn off the nitrogen after cooling down to room temperature. The product was washed three times with dilute sodium thiosulfate solution, washed three times with distilled water, and dried over anhydrous sodium sulfate to obtain a sample. The reaction conversion rate was determined to be 97.5% by ultraviolet absorption spectroscopy.

Embodiment 2

[0070] Weighed 100g of transgenic soybean oil (the mass fraction of linoleic acid was 50.88% and the mass fraction of linolenic acid was 6.86% as determined by gas chromatography, purchased from COFCO) and 0.1g of elemental iodine were placed in a three-necked flask, heated and stirred, and passed through immediately. Inject high-purity nitrogen (99.99%), reflux at 140°C for 2 hours, and then turn off the nitrogen after cooling down to room temperature. The product was washed three times with dilute sodium thiosulfate solution, washed three times with distilled water, and dried over anhydrous sodium sulfate to obtain a sample. The reaction conversion rate was determined to be 92.3% by ultraviolet absorption spectroscopy.

Embodiment 3

[0072] Weighed 100g of transgenic soybean oil (the mass fraction of linoleic acid was 50.88% and the mass fraction of linolenic acid was 6.86% as determined by gas chromatography, purchased from COFCO Group) and 1g of elemental iodine were placed in a three-necked flask, heated and stirred, and immediately passed into High-purity nitrogen, reflux at 100°C for 1 hour, and then turn off the nitrogen after cooling down to room temperature. The product was washed three times with dilute potassium iodide solution, washed three times with distilled water, and dried over anhydrous sodium sulfate to obtain a sample. The reaction conversion rate was 96.1% as determined by ultraviolet absorption spectrum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com