Fat meal for laying hens and preparation method thereof

A technology of fat powder and laying hens, which is applied in application, animal feed, additional food elements, etc., can solve the problems of insufficient energy intake of laying hens, reduce the burden of fat metabolism, have strong operability, and improve egg production The effect of rate and egg weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

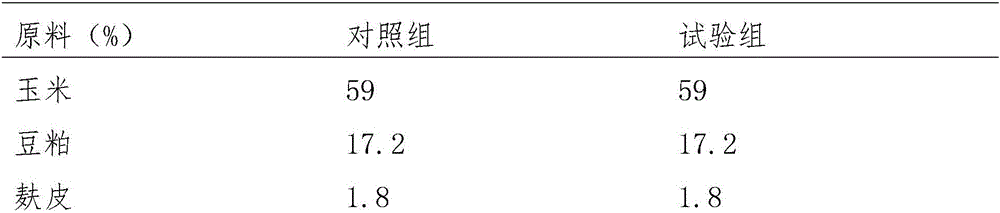

Image

Examples

Embodiment 1

[0034] Production of laying hen fat powder products with a crude fat content of 50%

[0035] A kind of fat powder that prevents fatty liver syndrome of laying hens is according to the following weight percentages:

[0036] 20 parts of palm kernel oil, 18 parts of sunflower oil, 7 parts of linseed oil, 5 parts of compound emulsifier, 5 parts of functional additives, 43 parts of carrier, 2 parts of dispersing agent;

[0037] The compound emulsifier includes 3 parts of modified soybean lecithin oil and 2 parts of mono- and diglycerides;

[0038] Functional additives include 4 parts of betaine and 1 part of Bacillus licheniformis;

[0039] The carrier includes extruded cornmeal;

[0040] Fluids include silica.

[0041] The preparation method of above-mentioned fat powder is as follows:

[0042] (1) Prepare raw materials;

[0043] (2) Mixed emulsification: put 200kg of palm kernel oil, 180kg of sunflower oil, 70kg of linseed oil, and 50kg of compound emulsifier into the emulsi...

Embodiment 2

[0048] Production of laying hen fat powder products with a crude fat content of 55%

[0049]A kind of fat powder that prevents fatty liver syndrome of laying hens is according to the following weight percentages:

[0050] 22 parts of palm kernel oil, 19 parts of sunflower oil, 8.5 parts of linseed oil, 5.5 parts of compound emulsifier, 5 parts of functional additive, 38 parts of carrier, 2 parts of dispersant;

[0051] The compound emulsifier includes 3 parts of modified soybean lecithin oil and 2.5 parts of mono- and diglycerides;

[0052] Functional additives include 4 parts of betaine and 1 part of Bacillus licheniformis;

[0053] The carrier includes extruded cornmeal;

[0054] Fluids include silica.

[0055] The preparation method of above-mentioned fat powder is as follows:

[0056] (1) Prepare raw materials;

[0057] (2) Mixed emulsification: Put 220kg of palm kernel oil, 190kg of sunflower oil, 85kg of linseed oil, and 55kg of compound emulsifier into the emulsifi...

Embodiment 3

[0062] Production of laying hen fat powder products with a crude fat content of 60%

[0063] A kind of fat powder that prevents fatty liver syndrome of laying hens is according to the following weight percentages:

[0064] 30 parts of palm kernel oil, 14 parts of sunflower oil, 10 parts of linseed oil, 6 parts of compound emulsifier, 5 parts of functional additive, 33 parts of carrier, 2 parts of dispersing agent;

[0065] The compound emulsifier includes 3 parts of modified soybean lecithin oil and 3 parts of mono- and diglycerides;

[0066] Functional additives include 4 parts of betaine and 1 part of dihydropyridine;

[0067] The carrier includes extruded cornmeal;

[0068] Fluids include silica.

[0069] The preparation method of above-mentioned fat powder is as follows:

[0070] (1) Prepare raw materials;

[0071] (2) Mixed emulsification: Put 300kg of palm kernel oil, 140kg of sunflower oil, 100kg of linseed oil, and 60kg of compound emulsifier into the emulsificati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com