Air-breathing photo-assisted biomass fuel cell and use thereof

A fuel cell, self-breathing technology, applied in the direction of aqueous electrolyte fuel cells, fuel cells, battery electrodes, etc., can solve the problems of few types, limit the absorption and utilization of sunlight, and achieve the effect of clean conversion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

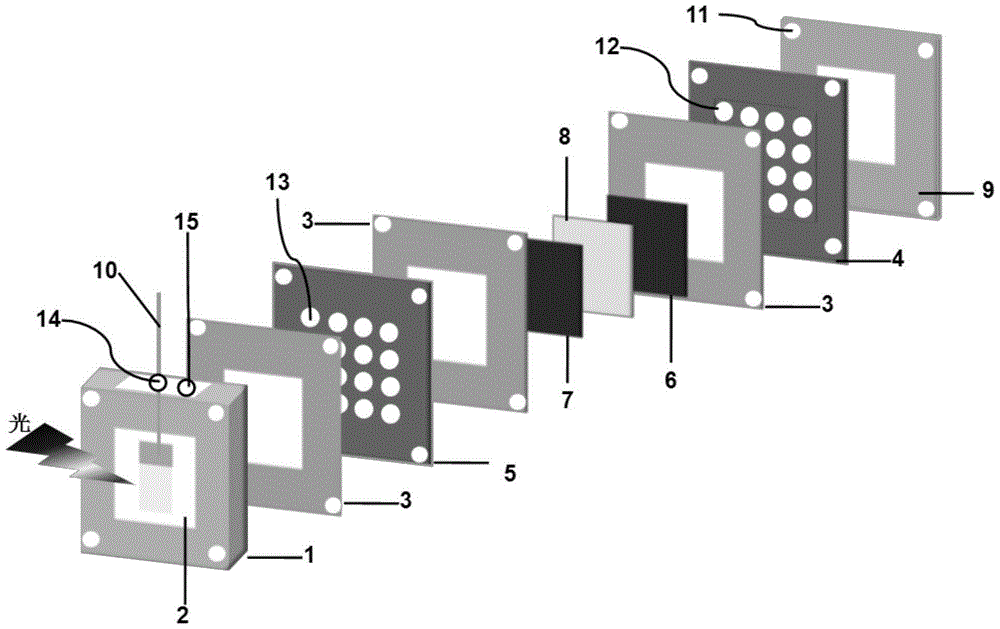

[0060] Such as figure 1 Shown is a self-breathing photo-assisted biomass fuel cell, including liquid storage cavity 1, optical window 2, sealing gasket 3, cathode collector plate 4, anode fixing plate 5, cathode gas diffusion layer 6, anode diffusion layer 7, Membrane electrode 8, end plate 9, photoanode 10.

[0061] Specifically, a sealing gasket 3 is respectively provided on the inner side of the anode fixing plate 5 and the cathode current collecting plate 4, a membrane electrode 8 is provided between the two sealing gaskets 3, and the membrane electrode 8 is provided with a cathode on the side of the cathode current collecting plate 4. The gas diffusion layer 6, the membrane electrode 8 is provided with an anode diffusion layer 7 on the side of the anode fixing plate 5, the cathode current collector plate 4 is provided with an end plate 9; the anode fixing plate 5 is provided with a liquid storage chamber 1, a liquid storage chamber There is a sealing gasket 3 between 1 and t...

Embodiment 2

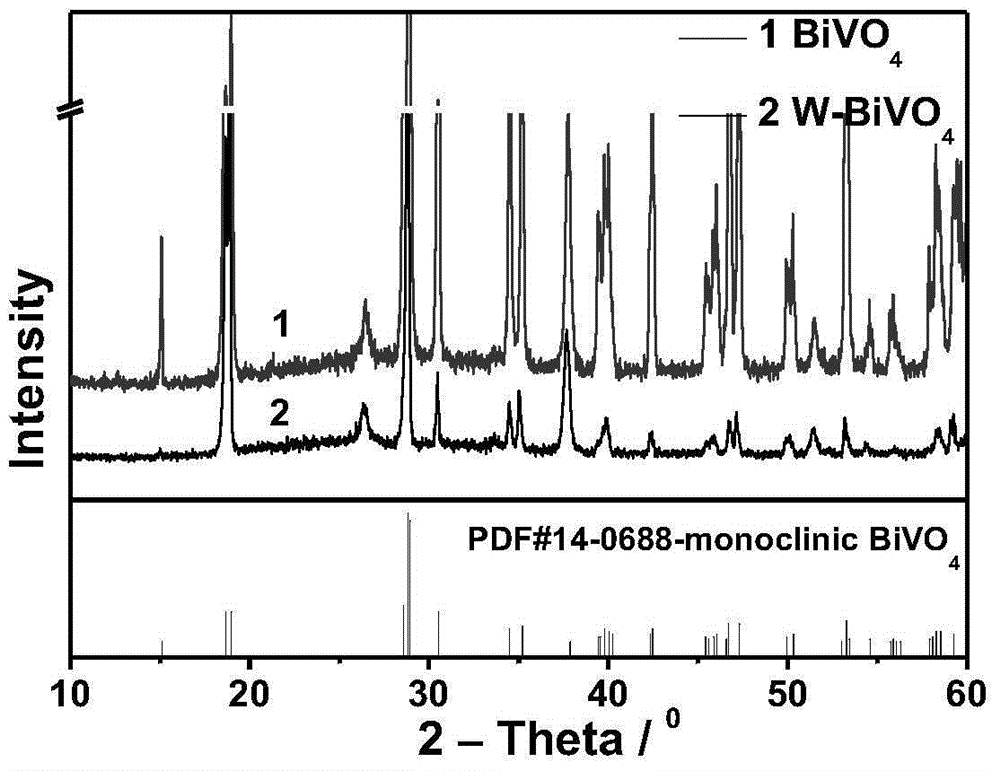

[0064] BiVO 4 And W-BiVO 4 Preparation of photoanode:

[0065] BiVO 4 Electrode or W-BiVO 4 The synthesis steps of the electrode are as follows:

[0066] BiVO 4 Preparation of photoanode: synthesis by constant potential deposition method. 202mL water plus 11mL 65% by mass concentrated HNO 3 , Said 8.75mmol VOSO 4 .xH 2 O is dissolved in the above solution, and 1.2133g Bi(NO 3 ) 3 .5H 2 O, 52g anhydrous sodium acetate adjust the pH to about 5.1, then add nitric acid to adjust the pH to 4.7. Use the above solution as the electrolyte, Pt sheet as the counter electrode, FTO as the working electrode, saturated calomel electrode SCE as the reference electrode, under the condition of 70℃ water bath constant temperature, use CHI760D electrochemical workstation to control the potential 1.855V vs. SCE, and deposit for 40 minutes Take out the cleaning, roast it in the air at 500℃ for 1h, the heating rate is 2℃ / min, and finally soak it with 1mol / L KOH for 15min to remove V 2 O 5 Impurities, t...

Embodiment 3

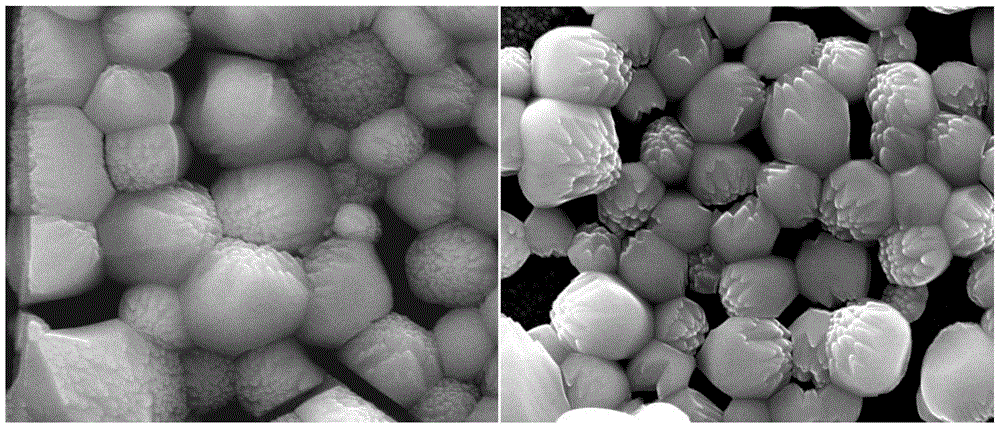

[0070] BiVO 4 And W-BiVO 4 Morphology characterization of photoanode:

[0071] BiVO 4 The electrode is composed of approximately spherical particles connected with each other, W-BiVO doped with W 4 Keep BiVO 4 The topography of the electrode, see the result image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com