Method for producing oil by co-pyrolysis of house refuse and forestry and agricultural residues

A technology for agricultural and forestry wastes and domestic wastes, which is applied in the field of co-pyrolysis of domestic wastes and agricultural and forestry wastes to prepare fuel oil, can solve problems such as insufficient self-sufficiency of pyrolysis energy, and achieves promotion of pyrolysis reaction, yield improvement, and technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

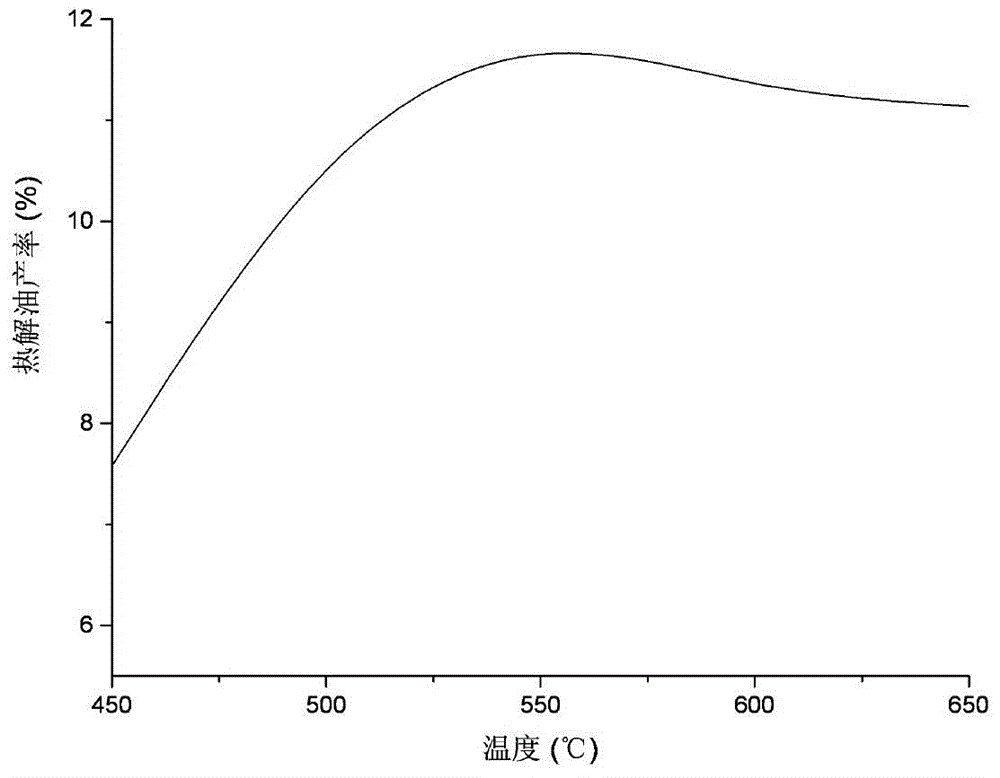

[0023] Mix domestic garbage and corn stalks evenly, the proportion of corn stalks in the mixed material is 50wt%, put the mixed material in a pyrolysis reactor, and heat from room temperature to 450°C to 650°C under anaerobic conditions, and the residence time is 30min. Volatile products enter the condensing device in gaseous form, non-condensable gas and pyrolysis coke backburn provide energy for the pyrolysis and drying process, and the condensed gas is recovered as pyrolysis liquid, which is separated from oil and water to obtain pyrolysis oil and water-soluble liquid . See the co-pyrolysis test results of domestic waste and corn stalks figure 2 , it can be found that in the range of the final pyrolysis temperature of 450°C to 650°C, with the increase of the pyrolysis temperature, the yield of pyrolysis oil first increases and then decreases, and the yield of pyrolysis oil reaches a maximum value of 11.94 at 550°C %.

Embodiment 2

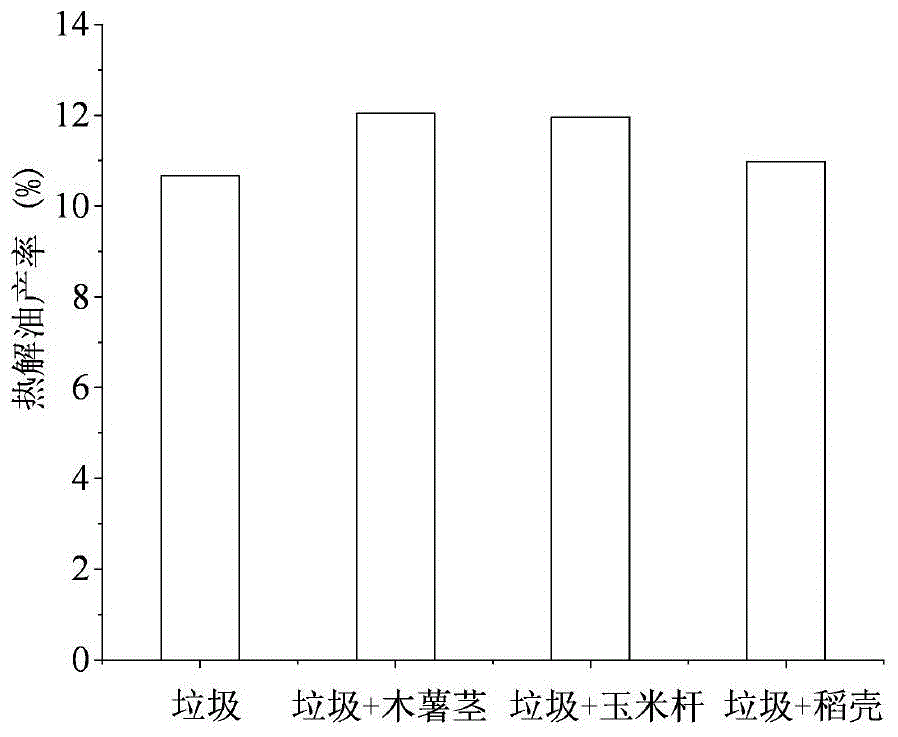

[0025] Mix domestic garbage with corn stalks, cassava stems, and rice husks evenly. The proportion of agricultural and forestry wastes in the mixed material is 50wt%. The mixed material is placed in a pyrolysis reactor and heated from room temperature to 550°C under anaerobic conditions. The residence time is 30min. Volatile products enter the condensing device in gaseous form, non-condensable gas and pyrolysis coke backburn provide energy for the pyrolysis and drying process, and the condensed gas is recovered as pyrolysis liquid, which is separated from oil and water to obtain pyrolysis oil and water-soluble liquid . The test results of co-pyrolysis of garbage and the above-mentioned agricultural and forestry wastes and separate pyrolysis of garbage are shown in image 3 , it can be seen that the yield of pyrolysis oil has been improved to varying degrees after adding agricultural and forestry wastes. Among them, the increase of pyrolysis oil yield after adding cassava ste...

Embodiment 3

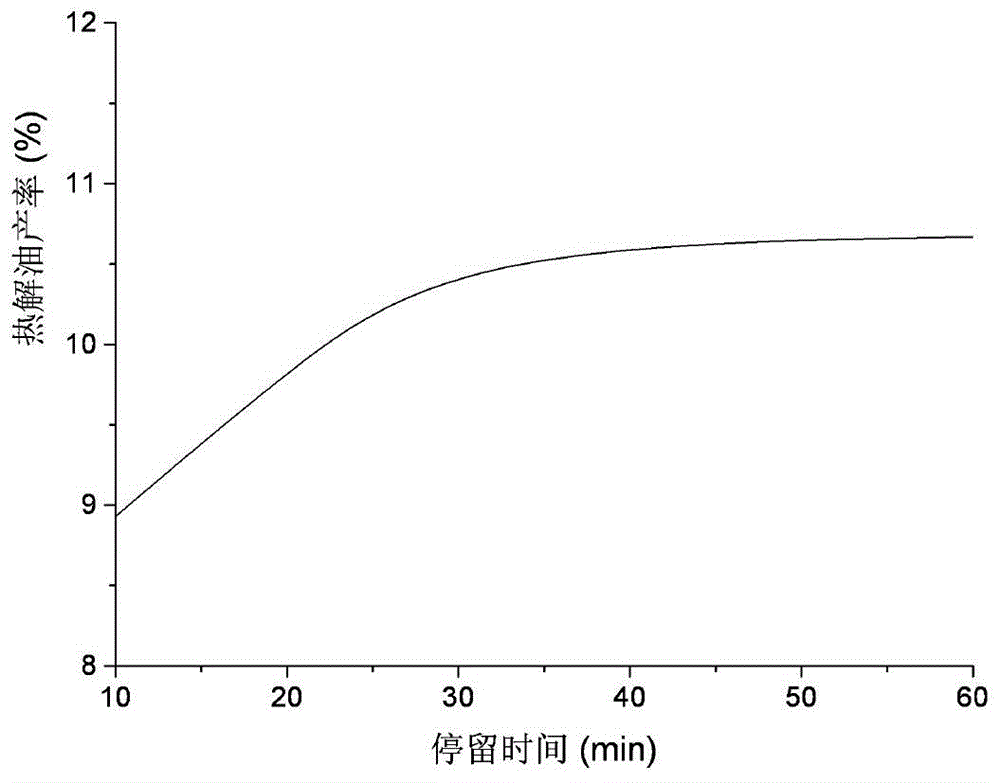

[0027] Mix domestic garbage and corn stalks evenly, the proportion of corn stalks in the mixed material is 0wt%, 10wt%, 30wt%, 50wt%, respectively, put the mixed material in a pyrolysis reactor, and heat it from room temperature to 550°C under anaerobic conditions , residence time 30min. Volatile products enter the condensing device in gaseous form, non-condensable gas and pyrolysis coke backburn provide energy for the pyrolysis and drying process, and the condensed gas is recovered as pyrolysis liquid, which is separated from oil and water to obtain pyrolysis oil and water-soluble liquid . The co-pyrolysis test results of domestic waste and different proportions of corn stalks are shown in Figure 4 , it can be seen that the yield of pyrolysis oil increases after adding different proportions of corn stalks. In the range of 0wt% to 50wt%, with the increase of the proportion of cornstalks, the yield of pyrolysis oil increases continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com