YIG (Yttrium Iron Garnet) band rejection filter based on planar resonant coupling structure and fabrication method of YIG band rejection filter

A band-stop filter and resonant coupling technology, which is applied to waveguide devices, electrical components, circuits, etc., can solve the problems of reducing the volume, weight and power consumption of magnetically tuned YIG band-stop filters, and achieve strong practical value and small size The effect of reducing cost, improving efficiency and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

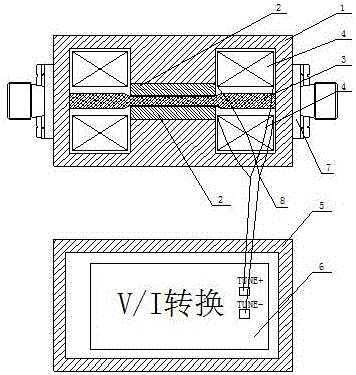

[0038] Embodiment 1: see Figure 1 to Figure 3 , a YIG band-stop filter based on a planarized resonant coupling structure 3, comprising a YIG band-stop filter and a driver, the YIG band-stop filter comprising a resonant cavity 14, and a planarized resonant coupling arranged in the resonant cavity 14 Structure 3, a permanent magnet bias magnetic circuit and an excitation coil 4 that provide a stable magnetic field for the resonant cavity 14;

[0039] The resonant cavity 14 is made of polyimide material, including an RF input end and an RF output end;

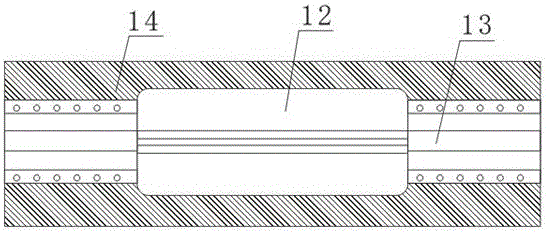

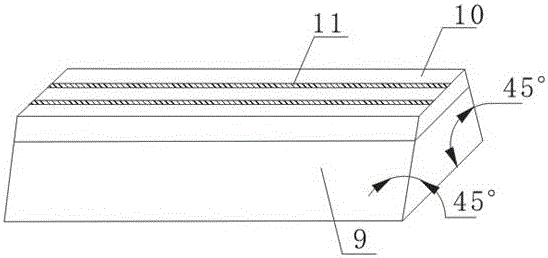

[0040] The planar resonant coupling structure 3 includes a YIG thin film circuit substrate 12 and microwave transmission circuit substrates on both sides thereof, the YIG thin film circuit substrate 12 includes a GGG glass 9, and the front side of the GGG glass 9 is provided with a YIG thin film 10, A coplanar waveguide circuit 11 is engraved on the upper surface of the YIG thin film 10 by sputtering lithography; the microwave t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com