Hybrid polyanion-type lithium manganese silicate positive electrode material and preparation method thereof

A polyanionic, lithium manganese silicate technology, applied in the field of materials science, can solve problems such as low conductivity and poor cycle stability, and achieve the effects of improving electrochemical performance, improving electronic conductivity and good cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

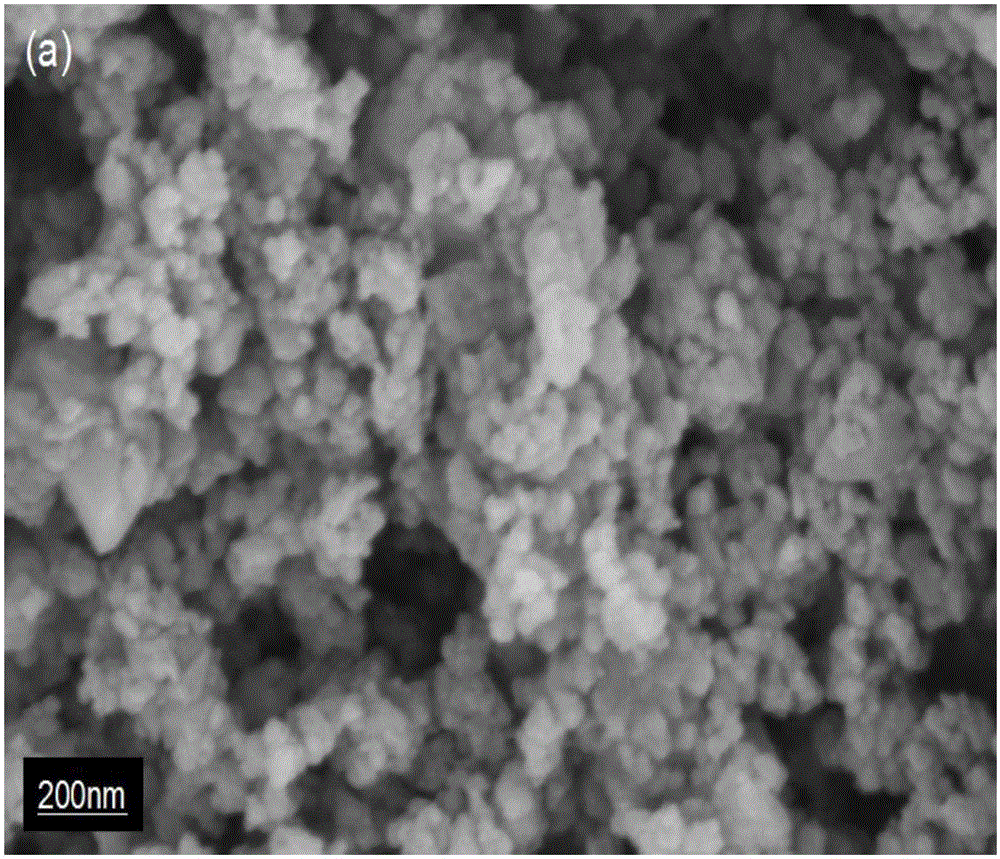

[0037] A mixed polyanionic manganese lithium silicate positive electrode material is carbon-coated boron-doped manganese lithium silicate, wherein the molecular formula of boron-doped manganese lithium silicate is Li 2+x MnB x Si 1-x o 4 / C, where x=0.06.

[0038] The above-mentioned preparation method of a mixed polyanionic manganese lithium silicate positive electrode material specifically comprises the following steps:

[0039] (1) Weigh 2.06mol lithium acetate dihydrate, 1mol manganese acetate tetrahydrate, 0.06mol boric acid and 90g citric acid in a container, add 500ml deionized water and stir to dissolve on a magnetic stirrer until the solid particles are completely dissolved , then add a mixed solution of absolute ethanol (94ml) and tetraethyl orthosilicate (263.2ml) to the solution, stir evenly, vibrate ultrasonically, then seal the mouth of the container, and keep the temperature in a closed reflux system in a water bath at 80°C for 12h to form a white Emulsion s...

Embodiment 1

[0044] A lithium-ion battery positive electrode material, i.e. carbon-coated boron-doped manganese lithium silicate, its molecular formula is Li 2 MnSiO 4 / C;

[0045] The preparation method of above-mentioned a kind of lithium-ion battery cathode material specifically comprises the following steps:

[0046] (1) Weigh 2 mol of lithium acetate dihydrate, 1 mol of manganese acetate tetrahydrate and 90 g of citric acid in a container, add 500 ml of deionized water and stir to dissolve on a magnetic stirrer until the solid particles are completely dissolved, then pour into the solution Add a mixed solution of absolute ethanol (100ml) and tetraethyl orthosilicate (280ml), stir evenly, oscillate ultrasonically, then seal the mouth of the container, keep the temperature in a closed reflux system in a water bath at 80°C for 12 hours to form a white milky sol, and then gradually heat To 80 ~ 82 ℃, the solvent evaporates, and finally slowly becomes a viscous sol;

[0047] C used abov...

Embodiment 2

[0051] A mixed polyanionic manganese lithium silicate positive electrode material is carbon-coated boron-doped manganese lithium silicate, wherein the molecular formula of boron-doped manganese lithium silicate is Li 2+x MnB x Si 1-x o 4 / C, where x=0.03.

[0052] The above-mentioned preparation method of a mixed polyanionic manganese lithium silicate positive electrode material specifically comprises the following steps:

[0053] (1) Weigh 2.03mol of lithium acetate dihydrate, 1mol of manganese acetate tetrahydrate, 0.03mol of boric acid and 90g of citric acid in a container, add 500ml of deionized water and stir to dissolve on a magnetic stirrer until the solid particles are completely dissolved , then add a mixed solution of absolute ethanol (97ml) and tetraethyl orthosilicate (271.6ml) to the solution, stir evenly, vibrate ultrasonically, then seal the mouth of the container, and keep the temperature in a closed reflux system in a water bath at 80°C for 12h to form a wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com