Thin film transistor

A technology of thin film transistors and semiconductors, applied in the direction of transistors, semiconductor devices, electric solid devices, etc., can solve the problems of not being able to improve the light transmittance of large-size TFTs, increase the area of the GDM circuit frame, etc., to improve the curing rate of the frame glue and reduce the size , the effect of saving wasted space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

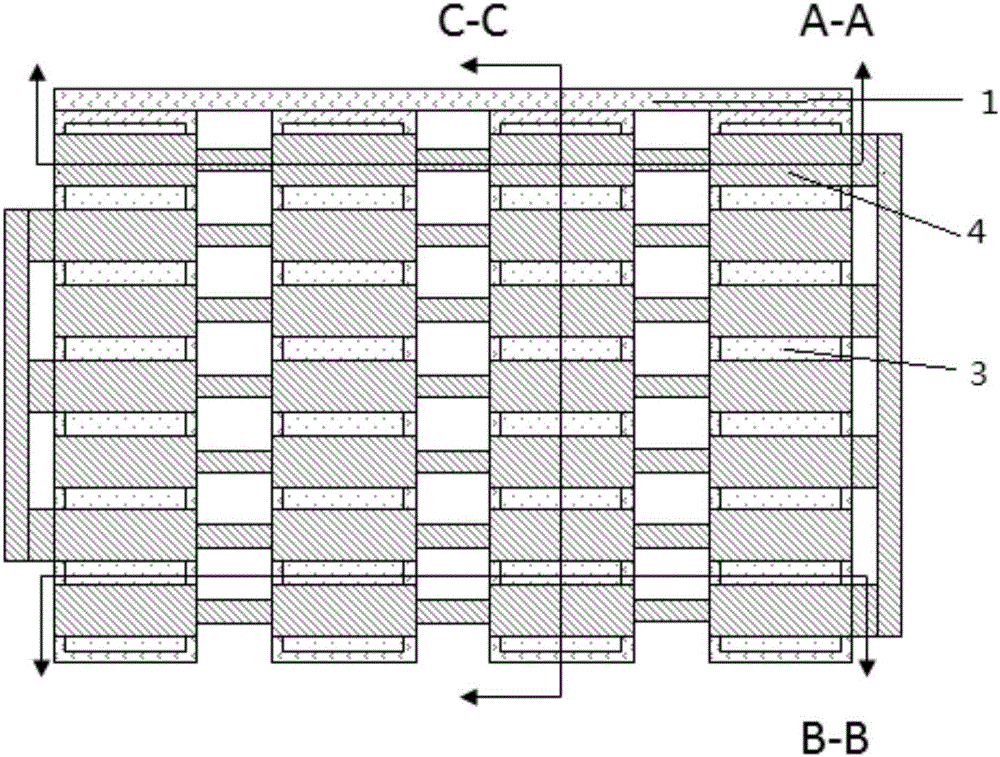

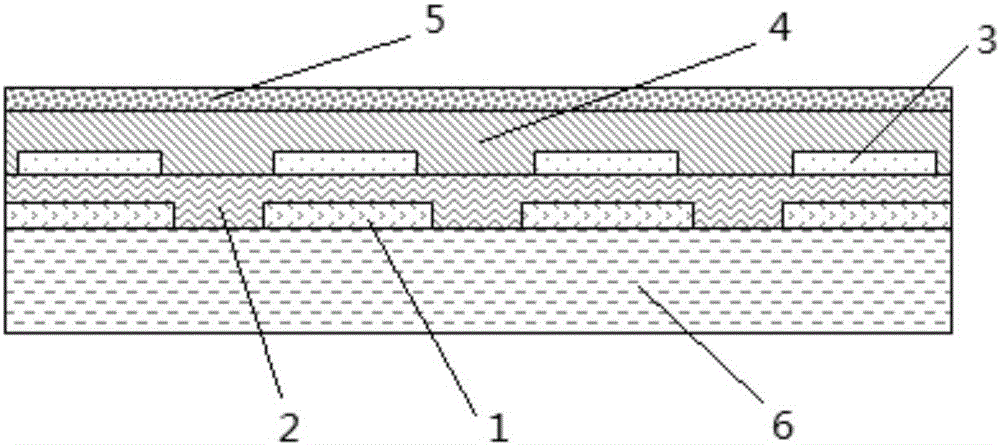

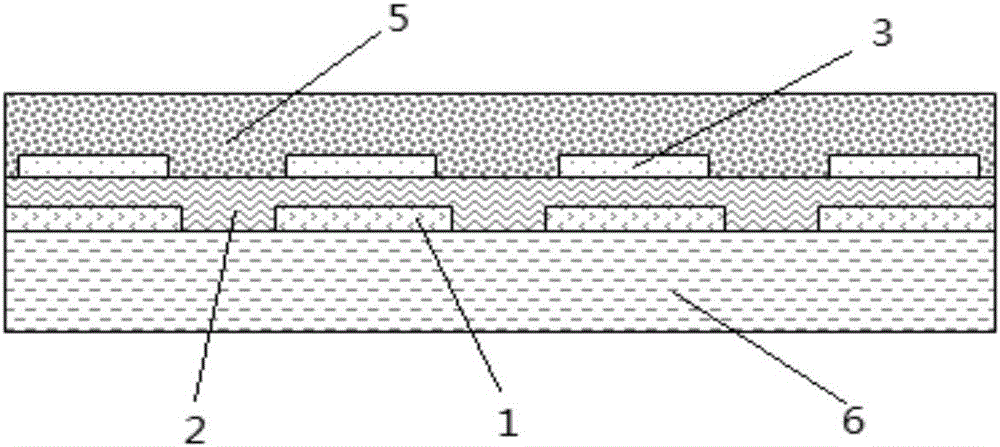

[0046] Such as Figure 1-4 As shown, it is a kind of thin film transistor of the present invention, which is a hollow type TFT with BCE structure, and there is no capacitance in the TFT. The hollow type TFT comprises a first metal layer gate (1), a first insulating layer gate insulating layer (2), a semiconductor layer (3), a second metal layer source drain (4) and a third insulating layer passivation layer (5); the first metal layer gate (1) is directly formed on the substrate glass layer (6), and the gate is formed from this layer of metal; the first insulating layer is located on the first metal layer gate (1) Above, a gate insulating layer is formed to separate the gate from the semiconductor layer (3); the semiconductor layer (3) is on the first insulating layer gate insulating layer (2); the second metal layer is used to form the source and drain , located on the semiconductor layer (3) directly in contact with the semiconductor layer (3), the third insulating layer pas...

Embodiment 2

[0049] Such as Figure 5-8 As shown, an improved thin film transistor based on Example 1 is a hollowed-out TFT with a BCE structure, and there is a capacitor in the TFT. The difference between Example 2 and Example 1 is that the gate metal line and the source drain The pole metal lines overlap, and the overlap forms a capacitor. Between the TFTs, a capacitor is formed due to the overlapping of the gate metal line and the source-drain metal line, and the capacitor is jointly formed by the first metal layer, the first insulating layer and the second metal layer. Because part of the capacitance has been formed in the TFT, the size of the original capacitance of the GDM circuit can be reduced in this way, thereby further reducing the frame width.

Embodiment 3

[0051] Such as Figure 9-12 As shown, it is a thin film transistor of the present invention, which is a hollow TFT with ES structure, and there is no capacitor in the TFT. The hollow-out TFT comprises a first metal layer gate (1), a first insulating layer gate insulating layer (2), a semiconductor layer (3), a second insulating layer etch barrier layer (7), and a second metal layer source The drain (4) and the third insulating layer passivation layer (5), the first metal layer gate (1) is directly formed on the substrate glass layer (6), and the gate is formed by this layer of metal; the first The insulating layer is located on the gate (1) of the first metal layer to form a gate insulating layer to separate the gate from the semiconductor layer; the semiconductor layer (3) is on the first insulating layer gate insulating layer (2); the second metal layer , for forming source and drain electrodes, located on the second insulating layer etching barrier layer (7), through the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com