A DIC technology-based method and system for on-site rock mass crack propagation pattern recognition in holes

A technology for crack propagation and pattern recognition, which is applied in the field of recognition of crack propagation patterns in on-site rock excavation and unloading, and achieves the effects of fast calculation speed, convenient operation and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

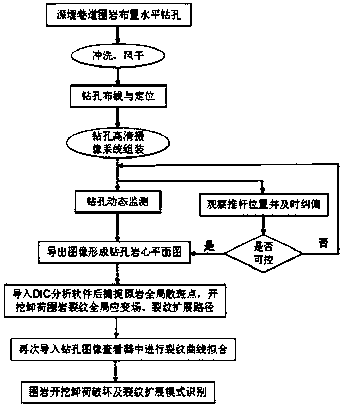

Method used

Image

Examples

Embodiment 1

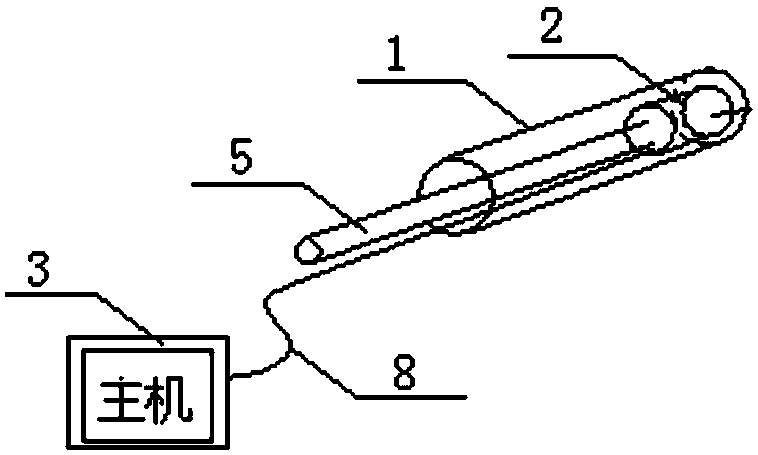

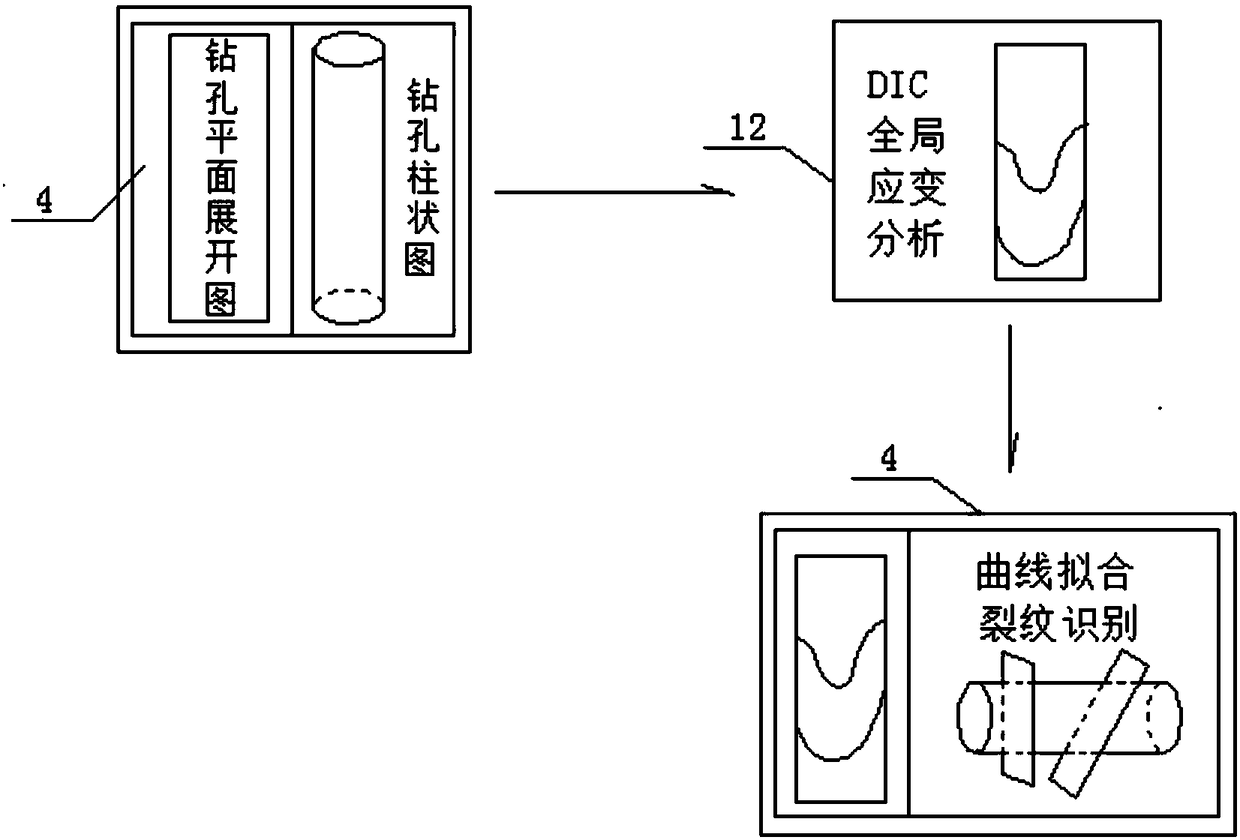

[0041] See attached figure 2 , 3 , 4, the present invention is based on DIC technology on-site rock mass crack propagation pattern recognition system in the hole, the recognition system includes a high-definition probe 2, a host 3, a push rod 5, a guide rod 6, and a cable 8; the high-definition probe 2 passes through the cable 8 is electrically connected to the host 3; two guide rods 6 are fixedly connected to the bottom of both sides of the HD probe 2 through black tape 7, and a push rod parallel to the axis of the HD probe 2 is fixedly connected to the center of the end face of the HD probe 2 5;

[0042] The host 3 includes an image viewer 4, DIC analysis and calculation software 12;

[0043] In this embodiment, the guide rod is a glue stick;

[0044] HD probe 2 is a 4D ultra-high-definition fully intelligent in-hole TV (GD3Q-GA type produced by Wuhan Good Technology Co., Ltd.);

[0045] DIC analysis and calculation software 12 is Gom correlate professional V8 software ...

Embodiment 2

[0047] See attached figure 2 , 3 , 4, 5, for a certain large-scale underground phosphate mine, adopt a kind of on-the-spot rock mass crack propagation pattern recognition method based on DIC technology of the present invention to identify its on-site rock mass crack propagation pattern in the hole.

[0048] Basic situation of the mine:

[0049] According to the specific geological data and mining technical conditions of the mining area, the development depth of the mine (the lower phosphorus 5 panel in the middle section of 640) has reached 600-700m from the surface, the vertical depth has exceeded 800m, the average thickness of the ore body is 6.07m, and the dip angle is 20-45. °, the ore body is mined using the strike longwall method. After drilling and coring the phosphate ore body in a certain stope in the panel area, it was found that the phosphate ore body and its surface have a relatively obvious difference in natural gray scale, which is because the mineral particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com