Silver electroplating coating composition, preparation method and application thereof

A technology of electroplating silver and composition, which is applied in anti-corrosion coatings, polyester coatings, cellulose coatings, etc., can solve problems such as difficulty in spraying electroplating silver coatings, inability to achieve wet spraying effects, easy discoloration of paint films, etc., to achieve The effect of improving crosslinking density and reactivity, suitable for industrial production, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

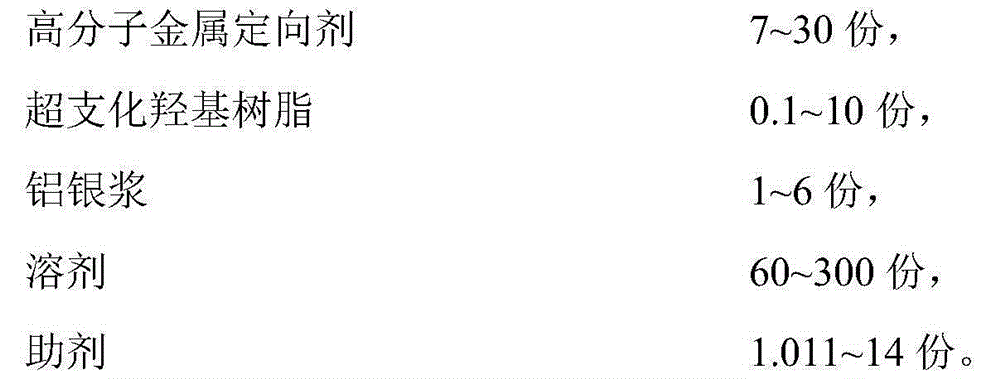

Method used

Image

Examples

Embodiment 1

[0055] Table 1

[0056] serial number

[0057] 9、

[0058] In the first container, add 0.2 part of hyperbranched hydroxyl resin to 13 parts of propylene glycol methyl ether acetate and 22.9 parts of butyl acetate, and stir evenly; in the second container, add 10 parts of butyl acetate and 10 parts of propylene glycol methyl ether Add 3.5 parts of aluminum silver paste VP12359 to the acetate, stir well, then add 0.05 parts of BYK-110, 4 parts of CAB381-20, 0.005 parts of BYK-320, and continue stirring evenly; add the mixture in the second container to the first container , and stir evenly; finally, add 20 parts of polymer metal directional agent KX-630 and 150 parts of S-100# solvent oil to the first container and stir evenly, the stirring time is 0.1~5h; the stirring speed is 100~700r / min, Thereby an electroplating silver coating composition was obtained.

Embodiment 2

[0060] Table 2

[0061] serial number

[0062] In the first container, add 0.4 part of hyperbranched hydroxyl resin to 13 parts of propylene glycol methyl ether acetate and 22.9 parts of butyl acetate, and stir evenly; in the second container, add 10 parts of butyl acetate and 10 parts of propylene glycol methyl ether Add 3.5 parts of aluminum silver paste VP12359 to the acetate, stir well, then add 0.05 parts of BYK-110, 4 parts of CAB381-20, 0.02 parts of BYK-320, and continue stirring evenly; add the mixture in the second container to the first container , stir evenly; finally add 30 parts of polymer metal directional agent KX-630 and 150 parts of S-100# solvent oil to the first container and stir evenly, the stirring time is 0.1~5h; the stirring speed is 100~700r / min, Thereby an electroplating silver coating composition was obtained.

Embodiment 3

[0064] table 3

[0065] serial number

[0066] In the first container, add 0.4 part of hyperbranched hydroxyl resin to 13 parts of propylene glycol methyl ether acetate and 22.9 parts of butyl acetate, and stir evenly; in the second container, add 10 parts of butyl acetate and 10 parts of propylene glycol methyl ether Add 3.5 parts of aluminum silver paste VP12359 to the acetate, stir well, then add 0.05 parts of BYK-110, 4 parts of CAB381-20, 0.02 parts of BYK-320, and continue stirring evenly; add the mixture in the second container to the first container , and stir evenly; finally, add 15 parts of polymer metal directional agent KX-630 and 150 parts of S-100# solvent oil to the first container and stir evenly, the stirring time is 0.1~5h; the stirring speed is 100~700r / min, An electroplating silver coating composition is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com