1300-1500 DEG C-resistant and low-density carbon tile surface anti-oxidation coating and production method thereof

An anti-oxidation coating and low-density technology, applied in the field of anti-oxidation coating and its preparation on the surface of low-density carbon tiles resistant to 1300-1500 ° C, can solve poor thermal insulation performance, low-density carbon tile density and low thermal insulation performance, etc. problem, to achieve the effect of good anti-oxidation performance, simple method, and aerobic diffusion barrier ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing an anti-oxidation coating on the surface of a low-density carbon tile, using Si-C, Si-B-C, Zr-Si-C, or Zr-Si-B-C and other ceramic precursors as carriers, through multiple brushing, Drying and pyrolysis to obtain an anti-oxidation base coating with a certain depth on the surface, and then obtain a surface sealing layer by high-temperature pre-oxidation smoothing treatment in an air atmosphere or by directly brushing a glassy oxide film, and finally obtain an anti-oxidation coating. Low density carbon tile material. The concrete steps of this method are:

[0036] 1) According to the shape characteristics and dimensions of different heat protection products, low-density carbon tiles are processed to ensure the processing accuracy and obtain low-density carbon tile base materials;

[0037] 2) Use the ceramic precursor to brush the low-density carbon tile base material obtained in step 1) for 3-4 times, and dry it once after each brushing to obtain u...

Embodiment 1

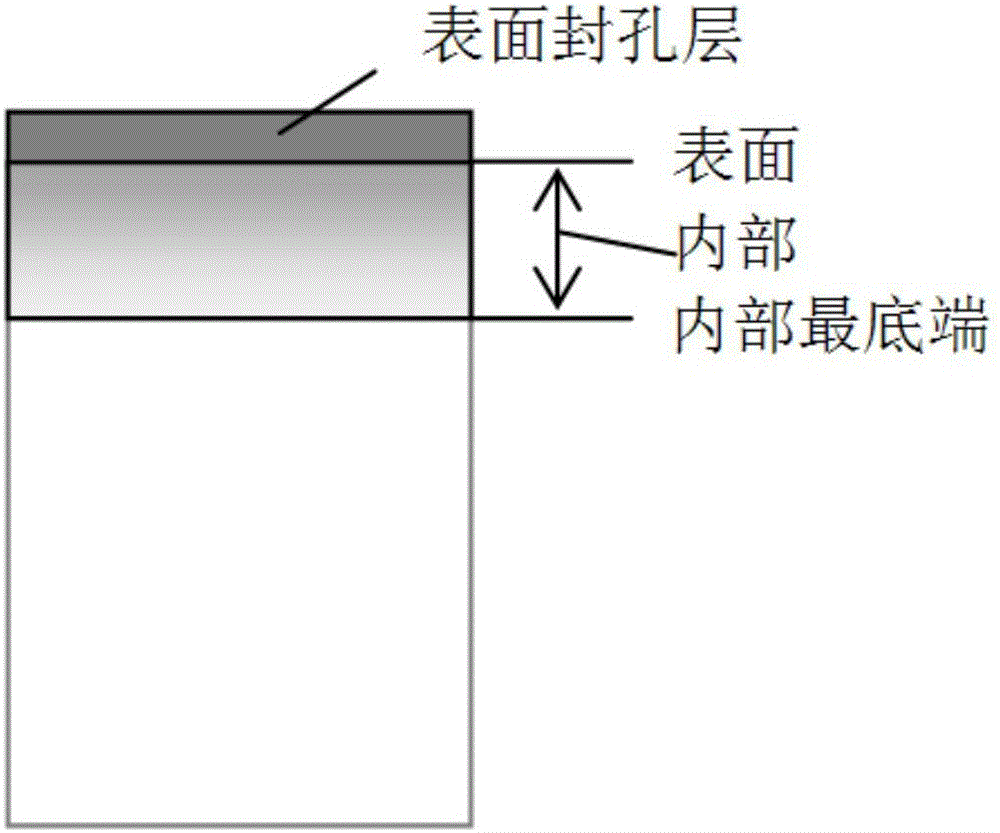

[0051] An anti-oxidation coating on the surface of a low-density carbon tile resistant to 1300-1500 °C, the anti-oxidation coating includes an anti-oxidation base coating and a surface sealing layer, wherein the anti-oxidation base coating is a refractory metal compound, and the refractory The metal compound enters the lowest position inside the low-density carbon tile to the top of the low-density carbon tile, which is the position on the surface of the low-density carbon tile, and its content increases successively, such as figure 1 shown; the thickness of the refractory metal compound is 2.1-2.6mm, and the elemental composition of the refractory metal compound includes Si, B and C; the surface sealing layer is a glass phase composed of Si, B and O, The thickness of the surface sealing layer is 35-50 μm;

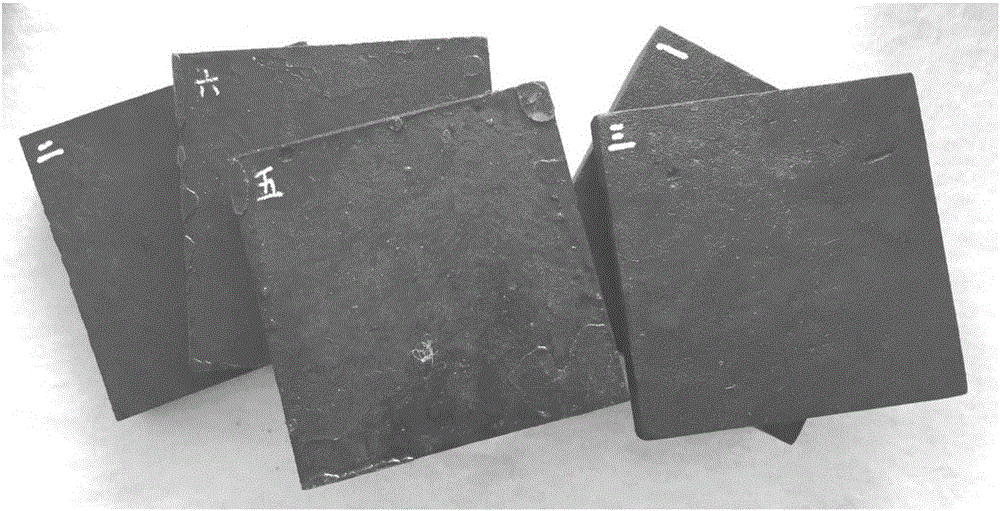

[0052] Aiming at the 100mm level flat sample, an anti-oxidation coating on the surface of low-density carbon tiles was designed and prepared, which includes an anti-oxidat...

Embodiment 2

[0062] An anti-oxidation coating on the surface of a low-density carbon tile resistant to 1300-1500 °C, the anti-oxidation coating includes an anti-oxidation base coating and a surface sealing layer, wherein the anti-oxidation base coating is a refractory metal compound, and the refractory The metal compound enters the lowest position inside the low-density carbon tile to the top of the low-density carbon tile, that is, the position on the surface of the low-density carbon tile, and its content increases successively; the thickness of the refractory metal compound is 2.0-2.5mm, and the refractory metal The element composition of the compound includes Si and C; the surface sealing layer is a glass phase composed of Si and O, and the thickness of the surface sealing layer is 45-50 μm;

[0063] Aiming at the 100mm level flat sample, an anti-oxidation coating on the surface of low-density carbon tiles was designed and prepared, which includes an anti-oxidation base coating and a su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com