Porous mullite-corundum ceramics preparation method

A technology of porous mullite and mullite, which is applied to ceramic products, applications, household appliances, etc., can solve the problems of reducing the mechanical strength of ceramic products, easy cracking of ceramic frames, and difficult control of air bubbles, so as to overcome difficult control and thermal expansion. The effect of small coefficient and easy factory construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

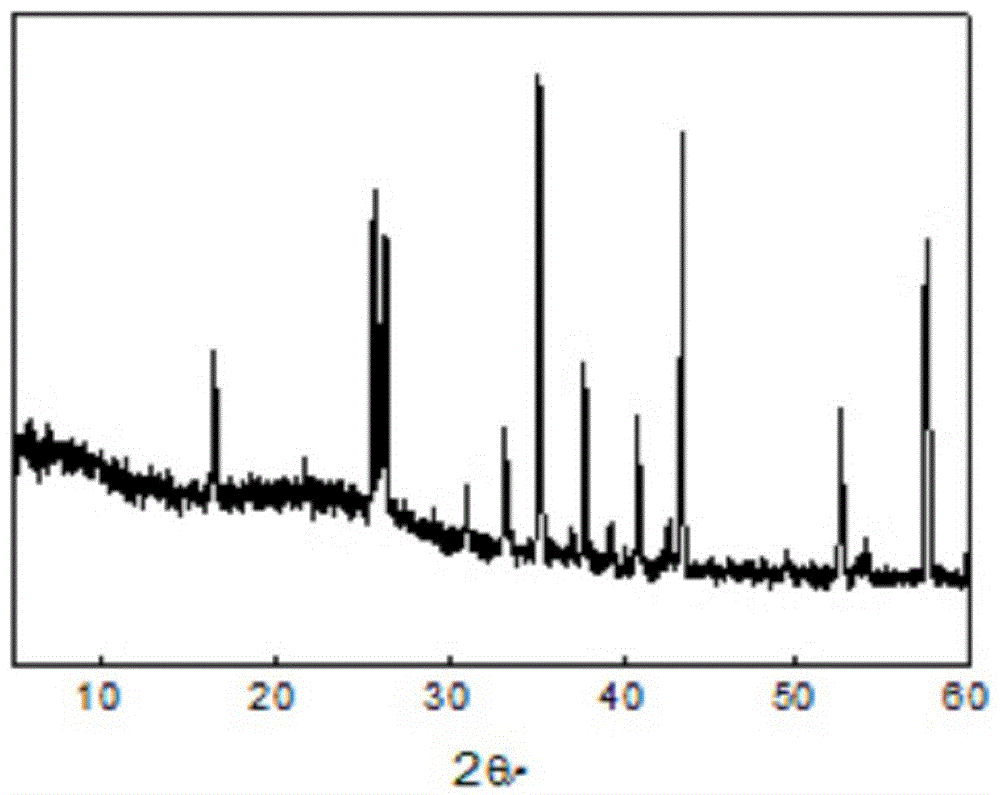

Image

Examples

Embodiment 1

[0018] A preparation method of porous mullite-corundum ceramics, comprising the following steps:

[0019] Weigh 320 grams of bauxite (2.825 moles of Al 2 o 3 ) and 80 g of diatomaceous earth (1.132 mol SiO 2 ) into the mill for continuous wet grinding for 12 hours, filter the slurry to obtain a filter cake, dry the filter cake in an oven at 110°C and grind to obtain a mixed powder, put the mixed powder in a container and add water (the amount of water and powder The weight ratio is 1.2:1) Stir for 30min, then add 20g starch, 2.0g triammonium citrate, 0.4g sodium carboxymethylcellulose and 0.6g silicone polyether emulsion (solid content 55wt%), stir well before adding 4g of sodium lauryl sulfate, stirred for 6 minutes to obtain a uniform and stable foam slurry and then injection molded, then placed the formed foam slurry in an oven at 40°C for 60 minutes, and demoulded to obtain a solidified foam body. Insulate in an oven at 110°C for 24 hours, cool naturally and place in an...

Embodiment 2

[0021] A preparation method of porous mullite-corundum ceramics, comprising the following steps:

[0022] Weigh 332 grams of bauxite (2.930 moles of Al 2 o 3 ) and 69 g of diatomaceous earth (0.976 mol SiO 2 ) into the mill for continuous wet grinding for 6 hours, filter the slurry to obtain a filter cake, dry the filter cake in an oven at 110°C and grind to obtain a mixed powder, put the mixed powder in a container and add water (the amount of water and powder The weight ratio is 1.2:1) and stir for 10min, then add 20g starch, 2.0g triammonium citrate, 0.2g sodium carboxymethylcellulose and 0.8g silicone polyether emulsion (solid content 55wt%), stir well and add 4.0 g sodium lauryl sulfate, stirred for 4 minutes to obtain a uniform and stable foam slurry, then injection molded, then placed the formed foam slurry in an oven at 70 ° C for 10 minutes, demolded to obtain a solidified foam body Put it in an oven at 140°C for 6 hours, and after natural cooling, place it in an e...

Embodiment 3

[0024] A preparation method of porous mullite-corundum ceramics, comprising the following steps:

[0025] Weigh 259 grams of bauxite (2.286 moles of Al 2 o 3 ) and 40.5 g of diatomaceous earth (0.573 mol of SiO 2 ) into the mill for continuous wet grinding for 11 hours, filter the slurry to obtain a filter cake, dry the filter cake in an oven at 110°C and grind to obtain a mixed powder, put the mixed powder in a container and add water (water and powder The weight ratio is 1.3:1) and stir for 30min, then add 15g starch, 1.5g triammonium citrate, 0.6g sodium carboxymethylcellulose and 0.2g silicone resin polyether emulsion (solid content 55wt%), stir well and then add 2.5 g sodium lauryl sulfate, stirred for 5 minutes to obtain a uniform and stable foam slurry, then injection molded, then placed the formed foam slurry in an oven at 40 ° C for 50 minutes, demolded to obtain a solidified foam body Put it in an oven at 110°C for 20 hours, cool it naturally and place it in an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com