High-toughness hybrid fiber reinforced concrete and a preparing method thereof

A technology of reinforced concrete and mixed fibers, which is applied in the field of building materials, can solve the problems such as the incorporation of nanoparticles and the reduction of concrete toughness, and achieve the effects of microstructure improvement, compactness, bending toughness and fracture toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The concrete (in 1 m 3 The method of preparation) is as follows:

[0062] (1) Weigh the following raw materials by weight:

[0063] Cement 390 kg (ordinary Portland cement with a strength grade of P.O 42.5, the same below),

[0064] Coarse aggregate 1140 kg (granite crushed stones with a particle size not greater than 20 mm, and the granite crushed stones are hard and well-graded, the same below),

[0065] Fine aggregate 650 kg (natural river sand with a fineness modulus of 2.76, the same below),

[0066] Fly ash 75 kg ( Grade fly ash with a fineness of 9.2%; manufacturer: Pingdingshan Yaomeng Power Plant, the same below),

[0067] Nano silica 25 kg (particle size less than 30 nm; manufacturer: Hangzhou Wanjing New Material Co., Ltd., the same below),

[0068] Polycarboxylate superplasticizer 5 kg (water reducing rate greater than 22%, manufacturer: Shanxi Huanghe New Chemical Co., Ltd., the same below),

[0069] water 165 kg,

[0070] Polyvinyl alcohol fiber 0....

Embodiment 2

[0088] The concrete (in 1 m 3 The preparation raw materials and weight are as follows:

[0089] 400 kg of cement, 1140 kg of coarse aggregate, 650 kg of fine aggregate, 75 kg of fly ash, 15 kg of nano-silica, 5 kg of polycarboxylate superplasticizer, 165 kg of water, 0.6 kg of polyvinyl alcohol fiber, Steel fiber 75 kg;

[0090] The preparation method is the same as in Example 1.

[0091] Gained concrete is tested, and test method is with embodiment 1, and result is as follows:

[0092] tested,

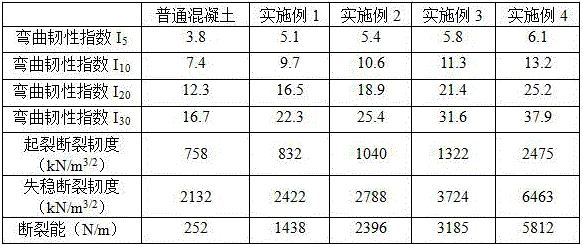

[0093] The obtained concrete flexural toughness index I 5 , I 10 , I 20 and I 30It can reach 5.4, 10.6, 18.9 and 25.4 respectively, which are 42%, 43%, 54% and 52% higher than ordinary concrete;

[0094] Crack initiation fracture toughness and instability fracture toughness can respectively reach 1040kN / m 3 / 2 and 2788kN / m 3 / 2 , respectively 37% and 31% higher than ordinary concrete;

[0095] The fracture energy can reach 2396N / m, which is 8.5 times higher than that of ordin...

Embodiment 3

[0097] The concrete (in 1 m 3 The preparation raw materials and weight are as follows:

[0098] 380 kg of cement, 1140 kg of coarse aggregate, 650 kg of fine aggregate, 75 kg of fly ash, 35 kg of nano-silica, 5 kg of polycarboxylate superplasticizer, 165 kg of water, 0.7 kg of polyvinyl alcohol fiber, Steel fiber 120 kg;

[0099] The preparation method is the same as in Example 1.

[0100] Gained concrete is tested, and test method is with embodiment 1, and result is as follows:

[0101] tested,

[0102] The obtained concrete flexural toughness index I 5 , I 10 , I 20 and I 30 It can reach 5.8, 11.3, 21.4 and 31.6 respectively, 53%, 53%, 74% and 89% higher than ordinary concrete;

[0103] Crack initiation fracture toughness and instability fracture toughness can respectively reach 1322kN / m 3 / 2 and 3724kN / m 3 / 2 , respectively 74% and 75% higher than ordinary concrete;

[0104] The fracture energy can reach 3185N / m, which is 11.6 times higher than that of ordinary con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com