Chlorine-free rust-proof concrete early strength water-reducing agent and preparation method thereof

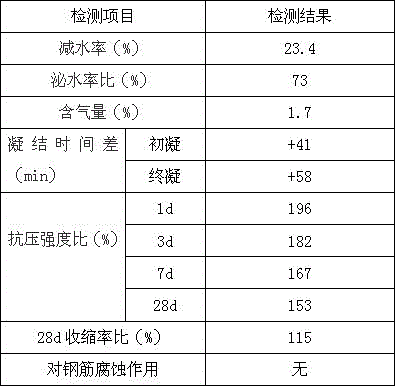

An early-strength water-reducing agent and concrete technology, applied in the field of concrete admixtures, can solve the problems of corrosion of concrete steel bars, cracking of concrete, inability to meet high-performance concrete and other problems, and achieve good early-strength effect, high water reduction rate, and anti-cracking effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] A chlorine-free antirust concrete early-strength water reducer, which is composed of the following raw materials by weight (kg): sulfonated melamine formaldehyde resin 16, p-aminobenzenesulfonate-sulfonated acetone-formaldehyde condensate 12, starch-acrylic acid glue Branch copolymer 10, calcium butyrate 6, sodium sulfate 8, magnesium chromate 6, poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt 12, pullulan 9, urea 4, polyacrylic acid Sodium6.

[0013] A preparation method of chlorine-free antirust concrete early-strength water reducer, comprising the following steps:

[0014] (1) The sulfonated melamine formaldehyde resin, p-aminobenzenesulfonate-sulfonated acetone-formaldehyde condensate, starch-acrylic acid graft copolymer, poly(4-styrenesulfonic acid-copolymerization-maleic acid) sodium salt Mix evenly, then add in the ball mill, control the ball-to-material ratio to be 8:1, the rotating speed is 550r / min, dry ball mill for 7h, then add pullula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com