A kind of preparation method of solid iron sulfate

A technology of solid sulfuric acid and ferrous sulfate, applied in the fields of ferric sulfate, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of high water insoluble matter, low product content, environmental pollution, etc., and achieve fast sedimentation speed and effect. Significant, cost-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

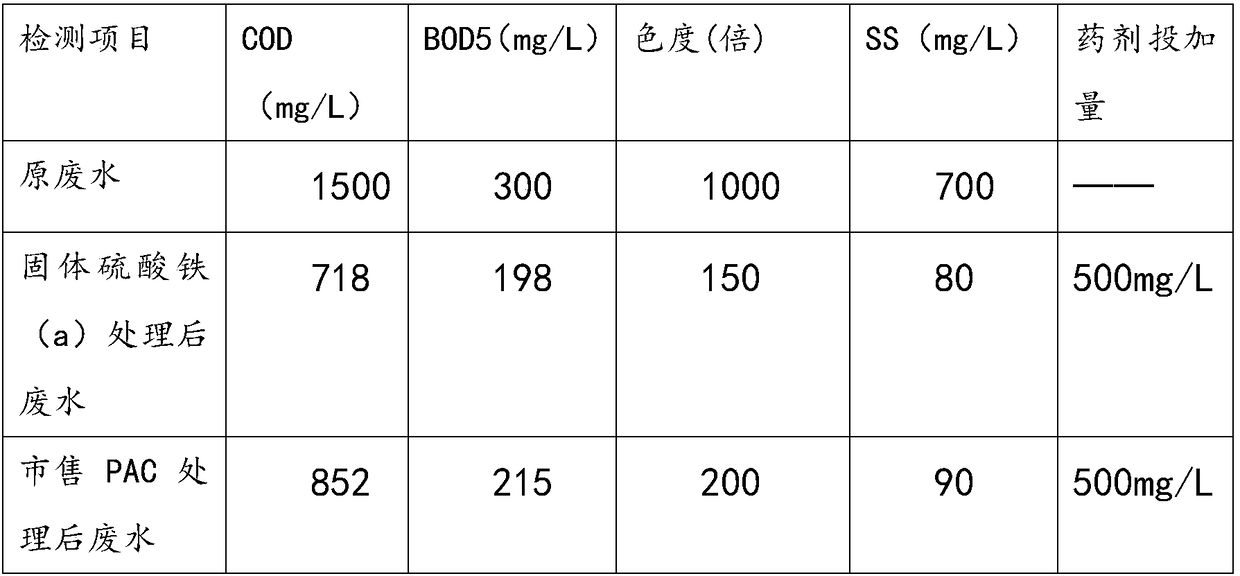

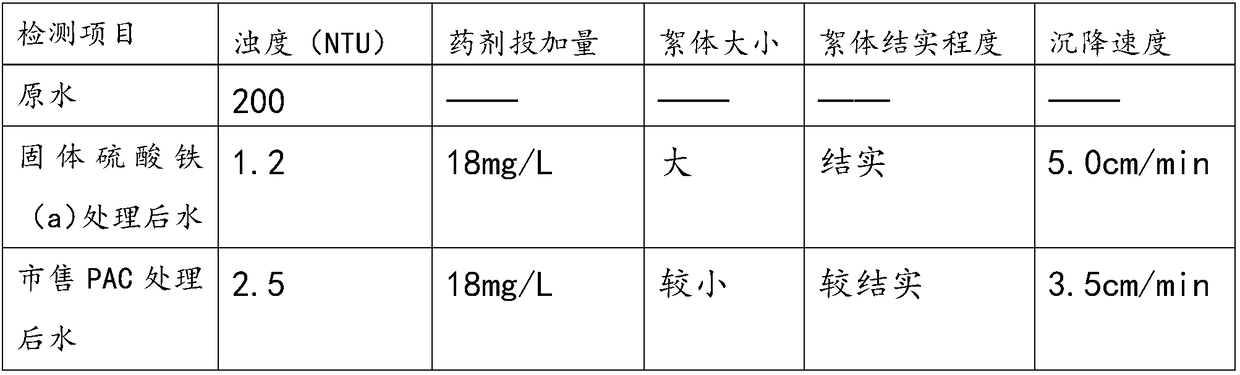

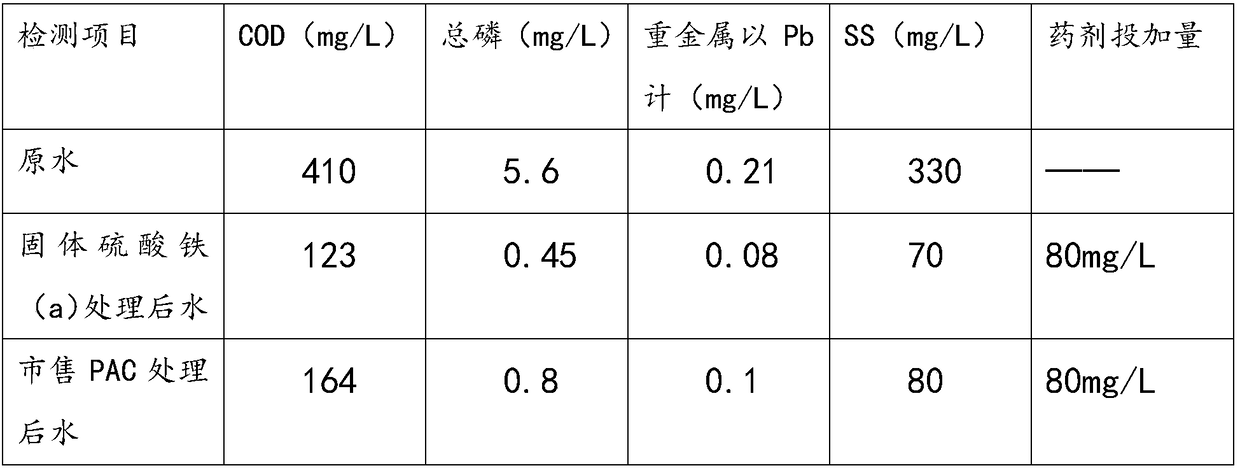

Examples

Embodiment 1

[0022] Add 180kg of 98% sulfuric acid into the reactor, then add 1000kg of titanium dioxide with an iron content of about 17% by-product ferrous sulfate to the reactor, and start stirring; dissolve 10kg of 99% sodium nitrite in 10kg The prepared catalyst is slowly added dropwise into the reactor, and the industrial oxygen valve is opened to continuously feed oxygen into the reactor after sealing the reactor. When the oxygen consumption reaches 18kg and the reaction time reaches 4 hours, the reaction When the temperature reaches about 80°C, take a sample to detect Fe 2+ If the mass fraction is less than 0.1%, add 1.0g of sodium carbonate, a crystallization and curing agent, and finally put the product into an open container, the product is about 2 / 3 of the height of the open container, and then put the open container containing the product into the environment In a system with a temperature of about 35°C, natural crystallization and drying for 24 hours can obtain a mass fractio...

Embodiment 2

[0027] Add 190g of 93% sulfuric acid into the reactor, then add 300g of industrial ferrous sulfate heptahydrate with an iron content of about 19% and 380g of industrial ferrous sulfate monohydrate with an iron content of about 30% to the reactor, start Stir; use 40g of nitric acid with a content of about 50% as a catalyst, slowly drop into the reactor, close the reactor, open the industrial liquid oxygen valve to vaporize it into oxygen, and continuously feed oxygen into the reactor. When the mass reaches 18g, after the reaction time reaches 2h, and the reaction temperature reaches about 70°C, take a sample to detect Fe 2+ If the mass fraction is less than 0.1%, add 0.8g of ammonium carbonate as a crystallization and curing agent, and finally put the product into an open container, the product is about 2 / 3 of the height of the open container, and then put the open container containing the product into the environment In a system with a temperature of about 25°C, natural crysta...

Embodiment 3

[0032] Add 220kg of 80% sulfuric acid into the reactor, then add 790g of industrial ferrous sulfate tetrahydrate with an iron content of about 21.5% to the reactor, and start stirring; add 20g of 99% industrial sodium nitrate and 99% Dissolve 20g of industrial sodium nitrite in 40g of water as a catalyst, then slowly add the prepared catalyst dropwise into the reactor, leave a small outlet hole in the reactor to lead to the tail gas absorption device, and pass compressed air into the reactor, When the volume of air introduced under the standard atmospheric pressure is 400 cubic meters, after the reaction time reaches 6 hours, and the reaction temperature reaches about 90°C, samples are taken to detect Fe 2+ If the mass fraction is less than 0.1%, add 0.8g of crystallization and curing agent calcium bicarbonate, and finally put the product into an open container, the product is about 2 / 3 of the height of the open container, and then put the open container containing the product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com