Pinion-and-rack driven elevator using planetary gear reducer

A technology of gear reducer and rack and pinion, which is applied to elevators, electrical components, electromechanical devices in buildings, etc., can solve problems such as increasing energy consumption, reducing the effective capacity of elevator cars, and increasing elevator car loads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

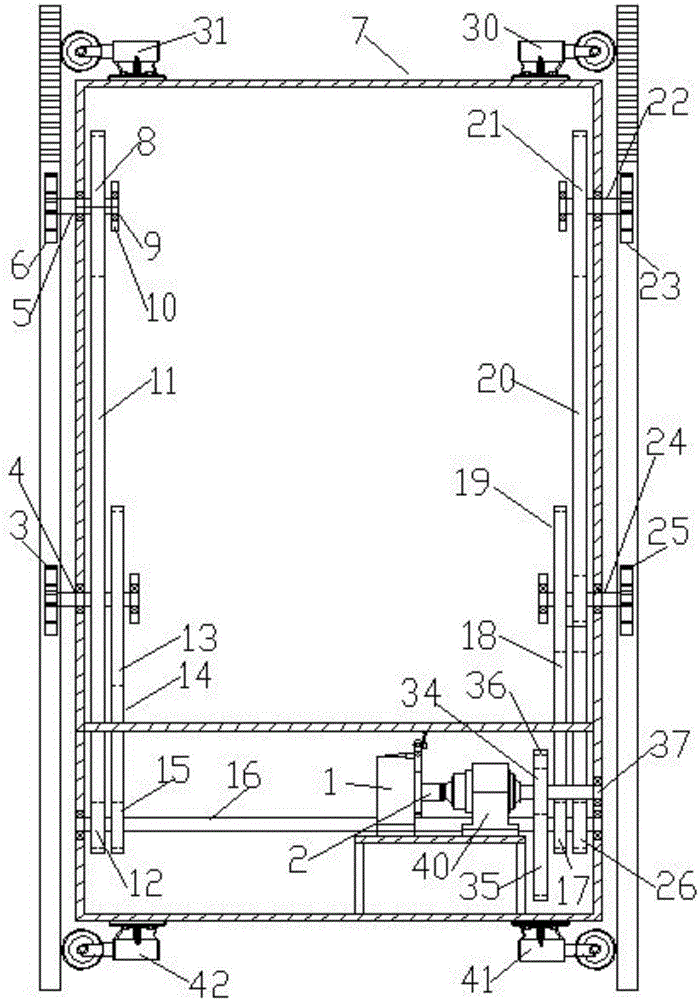

[0017] Embodiment 1, an outdoor construction ladder or indoor debris ladder or freight elevator, its structure and accessories Figure 1~4 Roughly the same, the description of the composition and function of its various parts can be found in paragraphs [0004], [0005], [0006], and [0007]. Considering that it matches its rated load, the planetary gear reducer used is a single-stage NGW planetary gear reducer, attached Figure 6 It is a schematic diagram of its transmission system. Its transmission relationship is that the input shaft 51 drives the sun gear 56 to rotate, and the sun gear 56 meshes with the transmission planetary gear 55 to rotate. The ring 54 (the inner surface of the ring is covered with teeth) meshes, and the ring gear 54 is fixed on the reducer housing 52, so the planetary gear 55 rotates on its own, and revolves around the sun gear 56 on the one hand, and drives the planetary carrier 53 through its rotating shaft Rotating around the central axis of the sun g...

Embodiment 2

[0018] Embodiment 2, this is a kind of elevator that load is bigger than embodiment 1, its structure and accessory Figure 1~4 Roughly the same, the description of the composition and function of its various parts can be found in paragraphs [0004] and [0005]. During installation, attention should be paid to the quality of the installation to ensure the necessary accuracy. Including ultrasonic flaw detection for the materials of drive gears and racks, using a laser elevator guide rail verticality measuring instrument to measure the verticality of the guide rails; the "power-off star connection" unit circuit in its electrical control system Figure 5 And [0006] paragraph described the same, its working principle is described in embodiment 1; The difference is that the planetary gear reducer that adopts is a two-stage NGW planetary gear reducer, with Figure 7 It is a schematic diagram of the transmission system, and its transmission relationship is that the input shaft 63 drives...

Embodiment 3

[0019] Embodiment 3, this is a kind of elevator similar to Embodiment 2, its structure and accessories Figure 1~4 Roughly the same, the description of the composition and function of its various parts can be found in paragraphs [0004] and [0005]. During installation, attention should be paid to the quality of the installation to ensure the necessary accuracy. Including ultrasonic flaw detection for the materials of drive gears and racks, using a laser elevator guide rail verticality measuring instrument to measure the verticality of the guide rails; the "power-off star connection" unit circuit in its electrical control system Figure 5And [0006] section described same, its working principle is described in embodiment 1; What adopt is the two-stage NGW planetary gear reducer that has gear coupling, it is not to pass between its high-speed stage and low-speed stage. The intermediate shaft is directly connected, but is connected through a gear coupling. In the planetary gear tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com