A blade clamping and centering adjustment device for an indexable blade peripheral grinder

A technology for indexing inserts and peripheral grinding machines, which is applied in the directions of grinding machine parts, grinding/polishing equipment, and workpiece feed motion control, etc. problems such as lowering, to achieve the effect of shortening processing auxiliary time, low manufacturing cost, and high centering accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

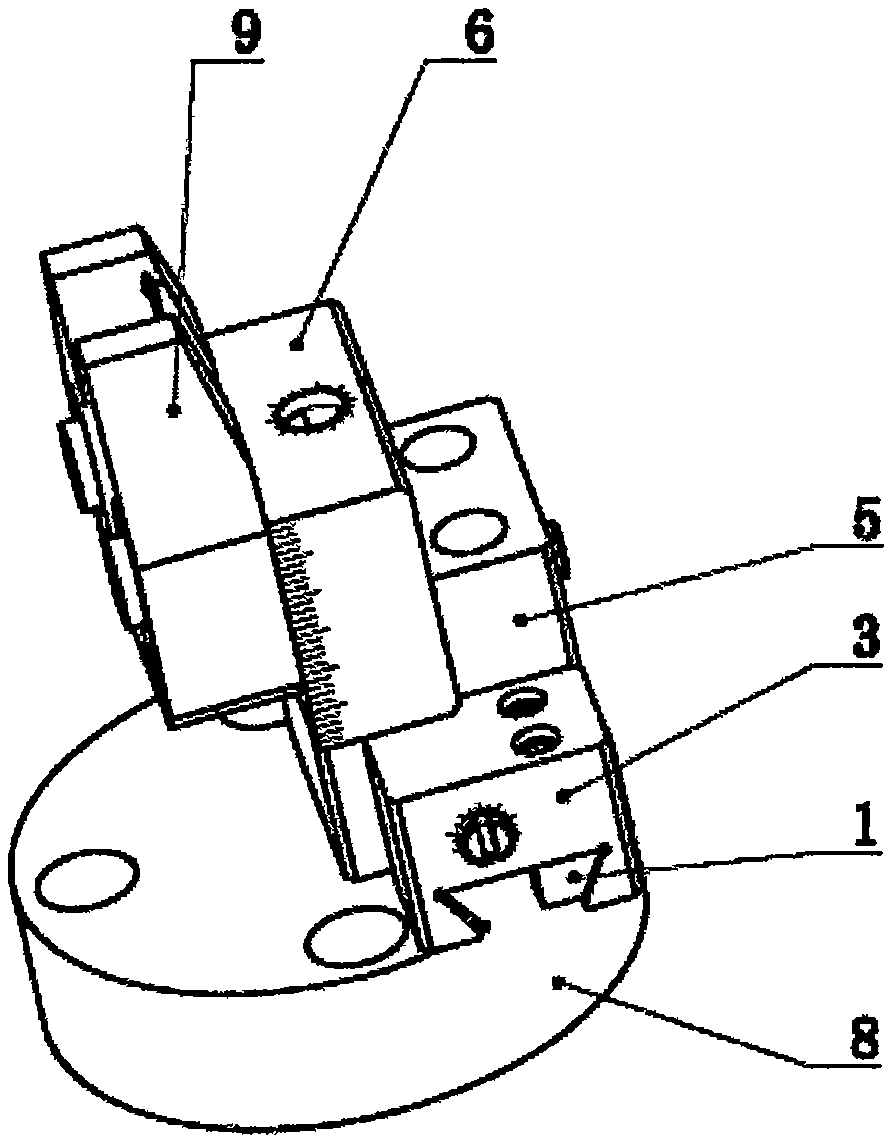

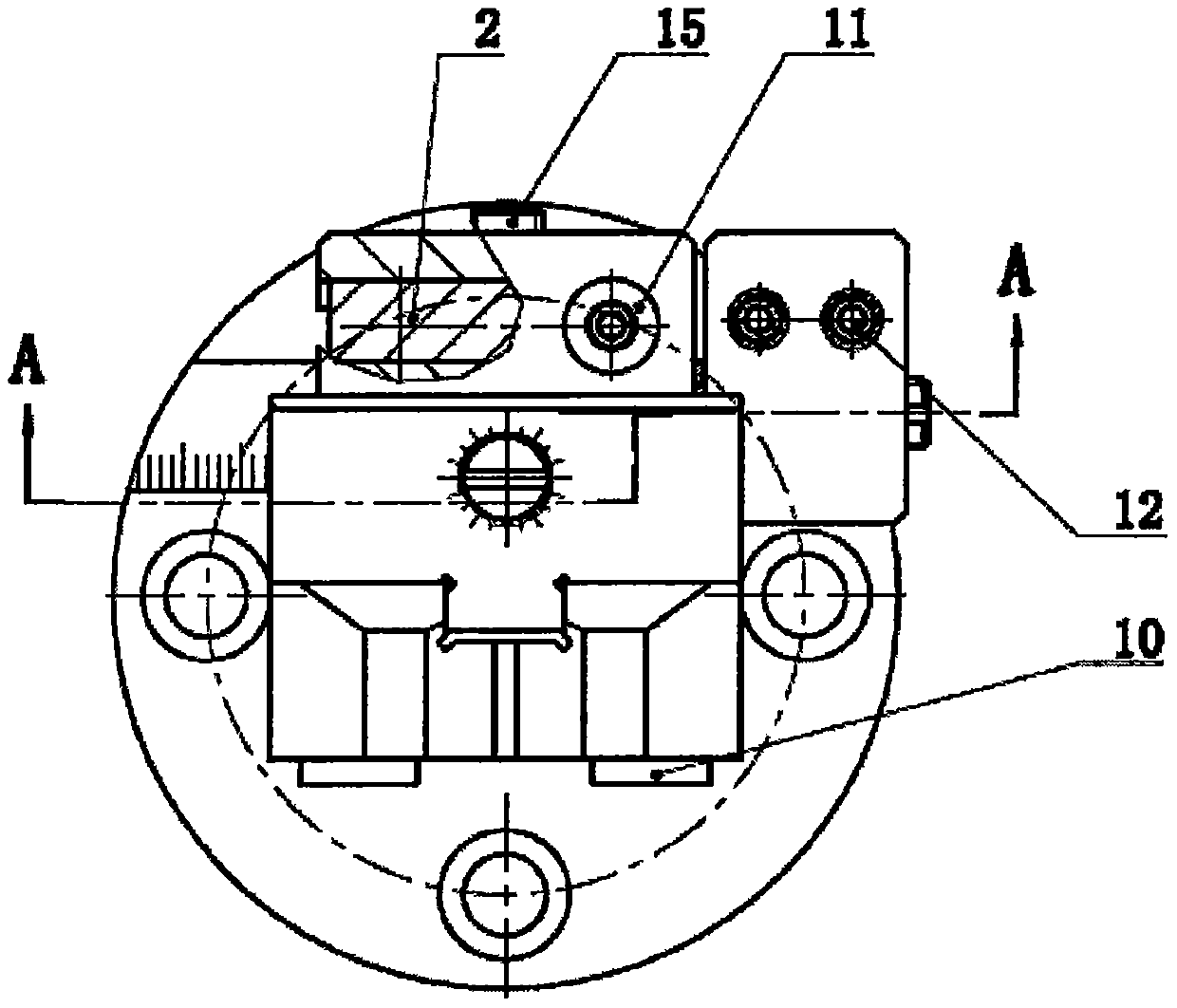

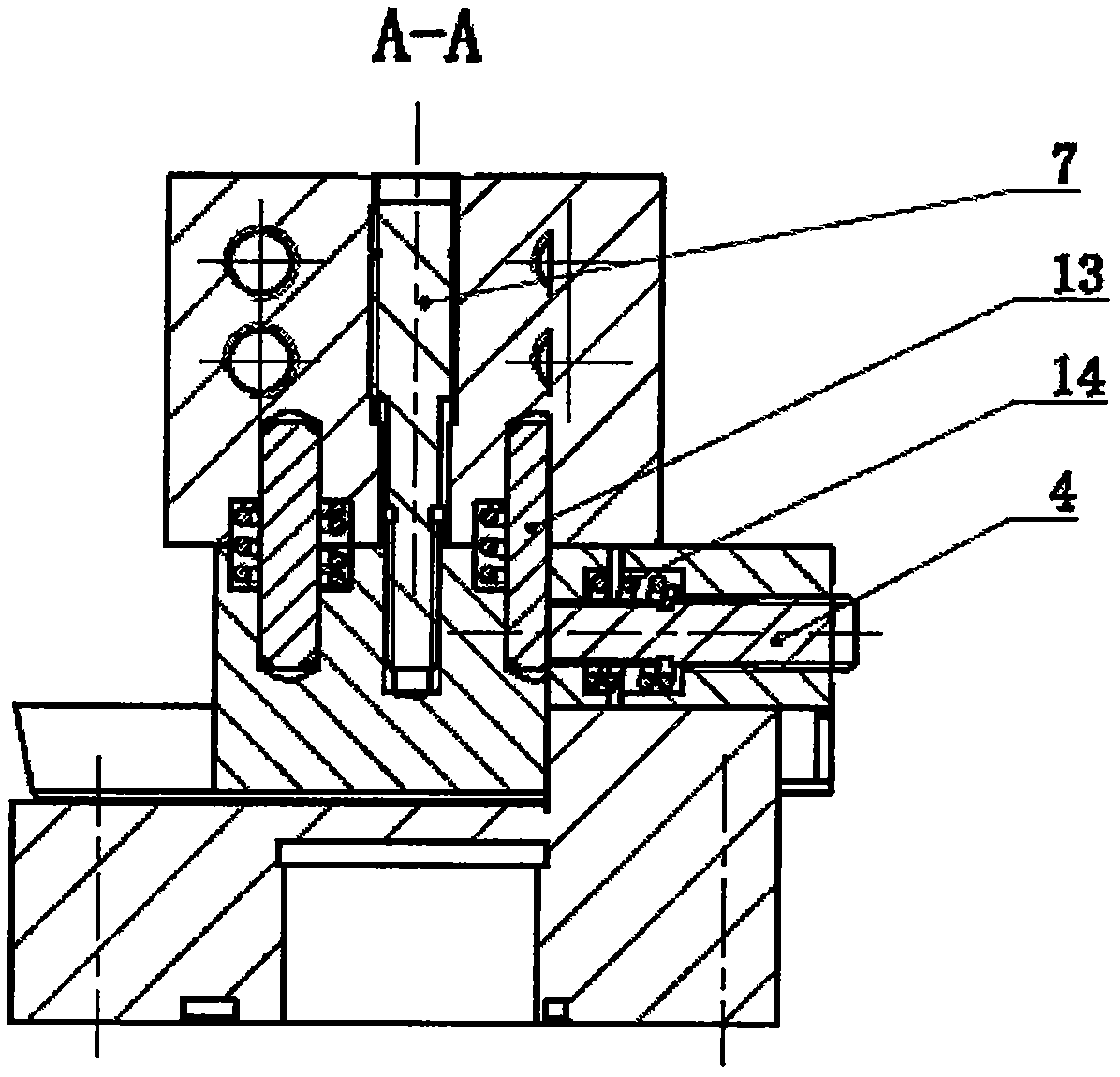

[0017] Such as figure 1 , 2 , 3, the present invention includes a V-shaped positioning block 9, a vertical moving block 6, a horizontal moving block 5, a guide fixing block 3, a flange seat 8, a horizontal differential screw 4, a vertical differential screw 7, and an A wedge Block 1, B wedge 2, guide post 13 and compression spring 14; the V-shaped positioning block 9 is installed on the vertical moving block 6; the horizontal moving block 5 passes through the dovetail groove on it, the B wedge 2 is connected with the flange seat 8; the guide fixed block 3 is connected with the flange seat 8 through the dovetail groove and the A wedge block 1; the vertical differential screw 7 is connected with the vertical moving block 6 and the horizontal The moving block 5 is provided with a guide column 13 and a compression spring 14 on the inner side of the joint for guiding and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com