Moderate-strength aluminum liquid cooled shell welding method

A welding method and shell technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as tiny cracks and weld sealing failure, and achieve the removal of welding residual stress, increase the sealing area, and improve the electron beam. Weldability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

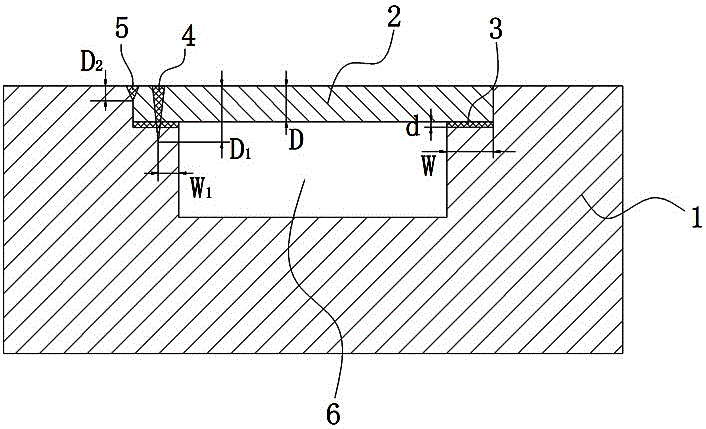

[0020] Such as figure 1 As shown, a method for welding a medium-strength aluminum liquid-cooled shell includes the following steps:

[0021] S1. Welding parts processing: According to the product structure and process size requirements, process the base plate 1 and the cover plate 2 respectively, process the cold runner 6 with steps on the base plate 1, and reserve 1mm margin for the shape of the base plate 1 and cover plate 2 ;

[0022] S2. Pre-treatment of parts: chemical cleaning and drying are used to remove oil and impurities on the surface of the workpiece. According to the needs, the fiber material 3 with a thickness of d is cut and assembled. The crystal solder Al88SiMg, with a thickness of 0.1mm, is used in superimposition according to the thickness d of the solder 3, and the cover plate 2 is fixed in the step of the base plate 1;

[0023] S3. Welding: the distance between the sealing weld 4 and the inner wall of the liquid-cooled flow channel 6 is W1, the penetrati...

Embodiment 2

[0027] Such as figure 1 As shown, a method for welding a medium-strength aluminum liquid-cooled shell includes the following steps:

[0028] S1. Welding parts processing: according to the product structure and process size requirements, process the base plate 1 and the cover plate 2 respectively, process the cold runner 6 with steps on the base plate 1, and reserve 0.8mm for the shape of the base plate 1 and cover plate 2 quantity;

[0029] S2. Pre-treatment of parts: chemical cleaning and drying are used to remove oil and impurities on the surface of the workpiece. According to the needs, the fiber material 3 with a thickness of d is cut and assembled. The crystal solder Al88SiMg, with a thickness of 0.07m, is used in superimposition according to the thickness d of the solder 3, and the cover plate 2 is fixed in the step of the base plate 1;

[0030] S3. Welding: the distance between the sealing weld 4 and the inner wall of the liquid-cooled flow channel 6 is W1, and the pe...

Embodiment 3

[0034] Such as figure 1 As shown, a method for welding a medium-strength aluminum liquid-cooled shell includes the following steps:

[0035] S1. Welding parts processing: According to the product structure and process size requirements, process the base plate 1 and cover plate 2 respectively, process the cold runner 6 with steps on the base plate 1, and reserve 0.5mm for the shape of the base plate 1 and cover plate 2 quantity;

[0036] S2. Pre-treatment of parts: chemical cleaning and drying are used to remove oil and impurities on the surface of the workpiece. According to the needs, the fiber material 3 with a thickness of d is cut and assembled. The crystal solder Al88SiMg, with a thickness of 0.05mm, is used in superimposition according to the thickness d of the solder 3, and the cover plate 2 is fixed in the step of the base plate 1;

[0037] S3. Welding: the distance between the sealing weld 4 and the inner wall of the liquid cooling channel 6 is W1, the penetration d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com