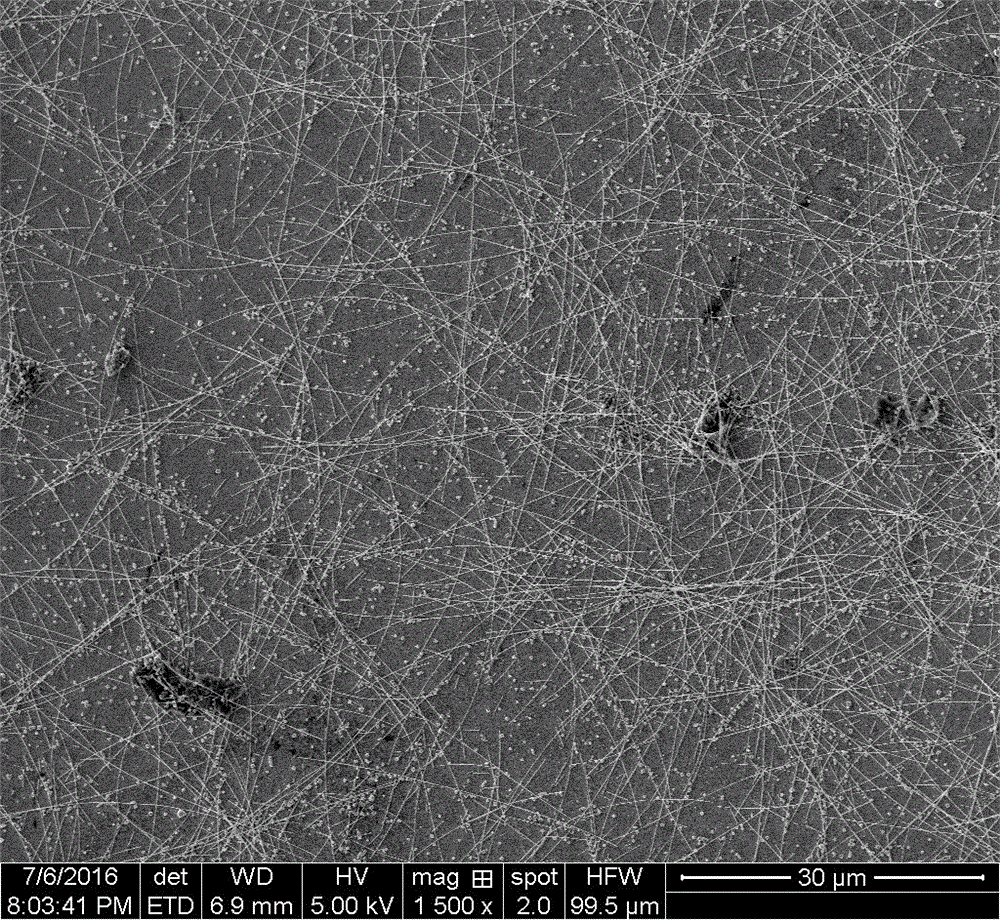

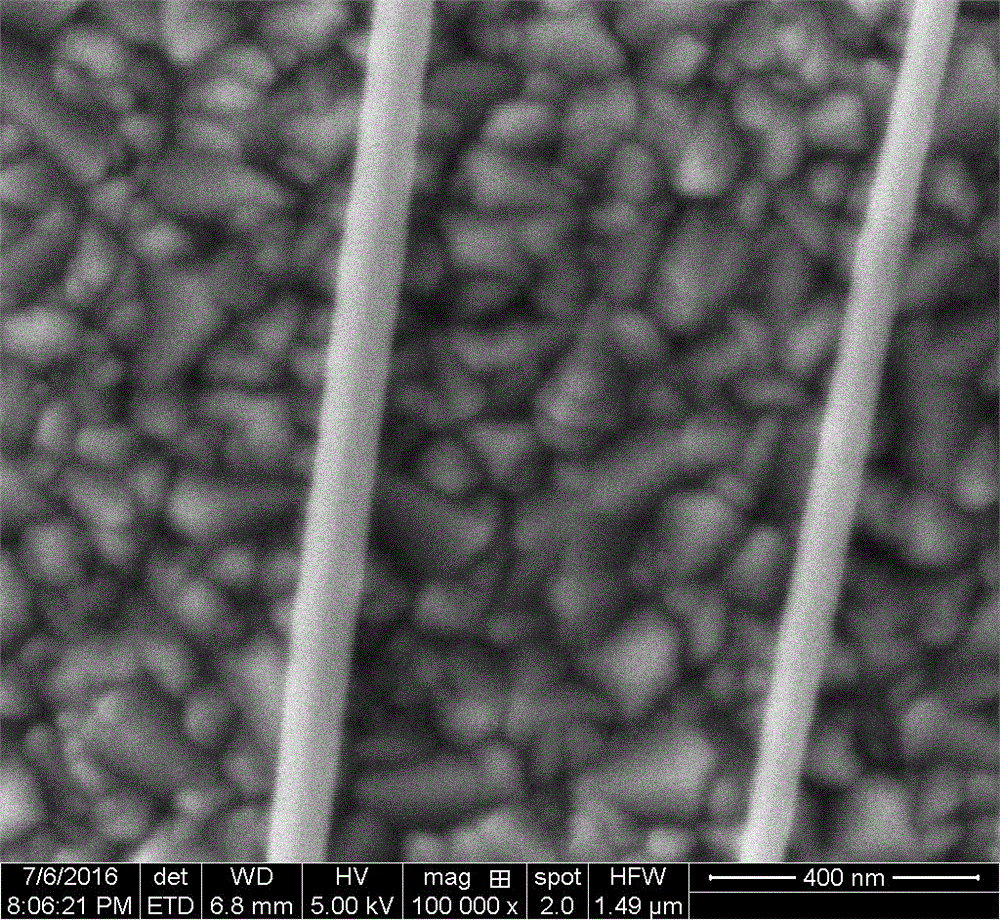

Method for preparing ultra-long silver nanowires through trace-salt-assisted polyol method

A technology of polyol method and silver nanowire, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of difficult to realize large-scale industrial production, low aspect ratio of silver nanowire, production To solve the problem of high cost, achieve the effect of low cost, good dispersion and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1: (1) get the anhydrous FeCl of 0.0018 g 3 Added to 100 mL of EG solution to prepare FeCl 3 / EG solution, and take 15 mL for later use; (2) Add 0.34g PVP to the above 15 mL FeCl 3 / EG solution at 170 o Heating and stirring under C conditions; (3) 0.13 g of AgNO 3 Dissolve in 5 mL ethylene glycol solution; (4) Take 0.030 g of AgNO 3 Join in step (2), at 170 o Stir at a slow speed under C heating conditions; (5) gradually add the solution prepared in step (3) dropwise to the solution prepared in step (4) within 10 min, at 170 o Continue to stir slowly under the condition of C, and the reaction time is 0.5 h; (6) After cooling the solution prepared in step (5) at room temperature, use a mixture of acetone and ethanol (1:1) and ethanol solution at 9000 rpm respectively Centrifuge and wash 3 times, then disperse in ethanol solution.

Embodiment 2

[0018] Embodiment 2: (1) get the anhydrous FeCl of 0.0018 g 3 Added to 100 mL of EG solution to prepare FeCl 3 / EG solution, and take 15 mL for later use; (2) Add 0.34 g PVP to the above 15 mL FeCl 3 / EG solution at 170 o Heating and stirring under C conditions; (3) 0.16 g of AgNO 3 Dissolve in 5 mL ethylene glycol solution; (4) Take 0.030 g of AgNO 3 Join in step (2), at 170 o Stir at a slow speed under C heating conditions; (5) the solution prepared in step (3) is gradually added dropwise to the solution prepared in step (4) within 5 min, at 170 o Continue to stir slowly under the condition of C, and the reaction time is 0.5 h; (6) After cooling the solution prepared in step (5) at room temperature, use acetone and ethanol mixture (1:1) and ethanol solution at 9000 rpm respectively Centrifuge and wash 3 times, then disperse in ethanol solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com