Defective engine block recycling method in continuous casting line

A technology for engine cylinder blocks and casting production lines, which is applied to engine components, cylinders, mechanical equipment, etc., can solve problems such as complex equipment, and achieve the effect of reducing recovery costs and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

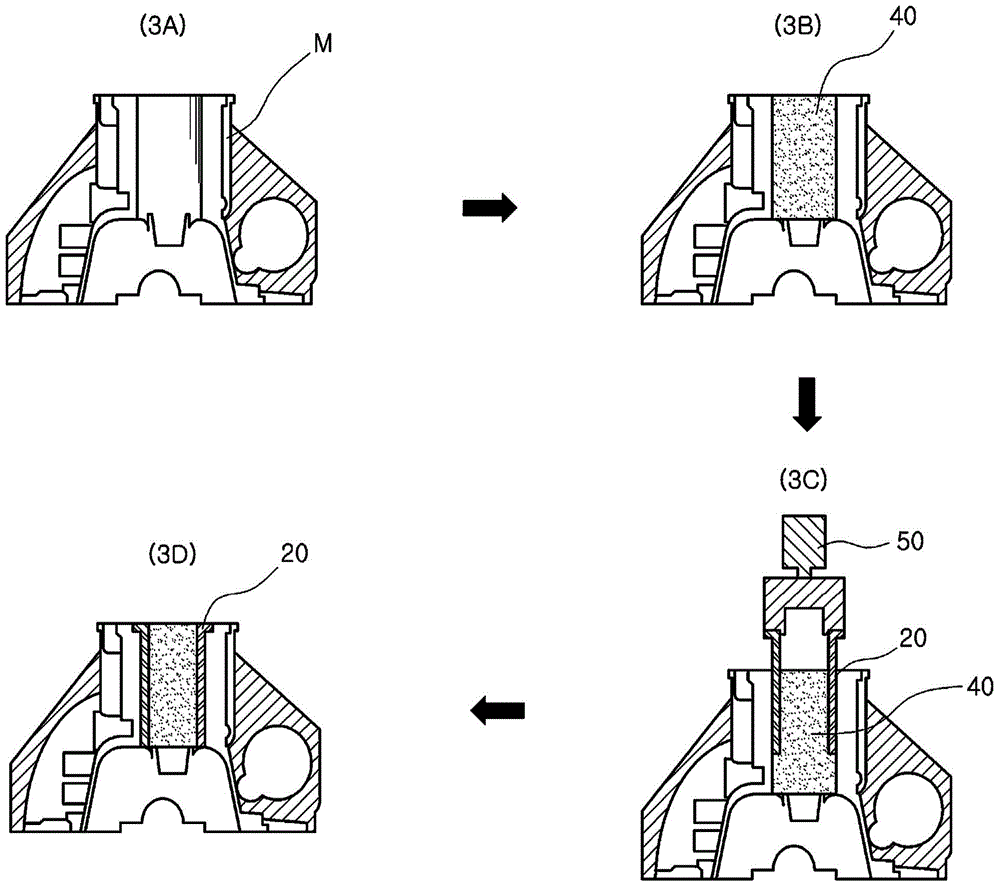

[0054] Now, will refer to Figure 5 with Image 6 A preferred embodiment of the method for recycling defective engine cylinders in a continuous casting production line according to the present invention is described.

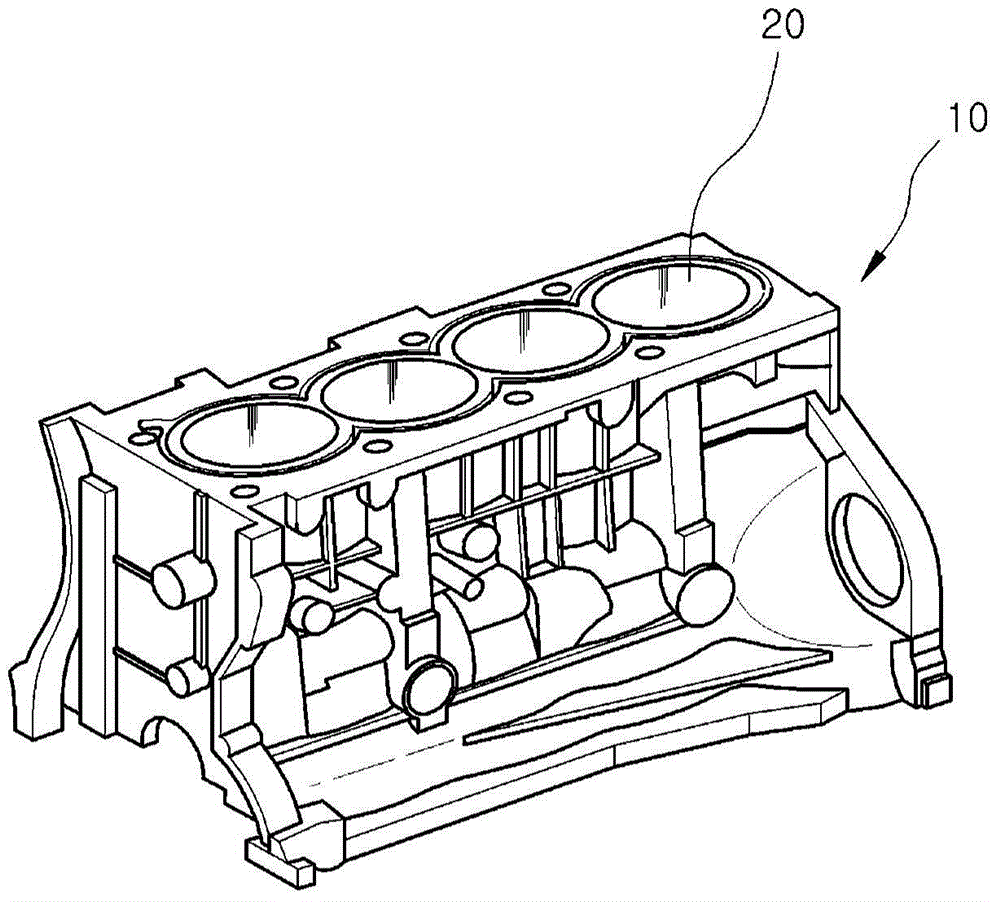

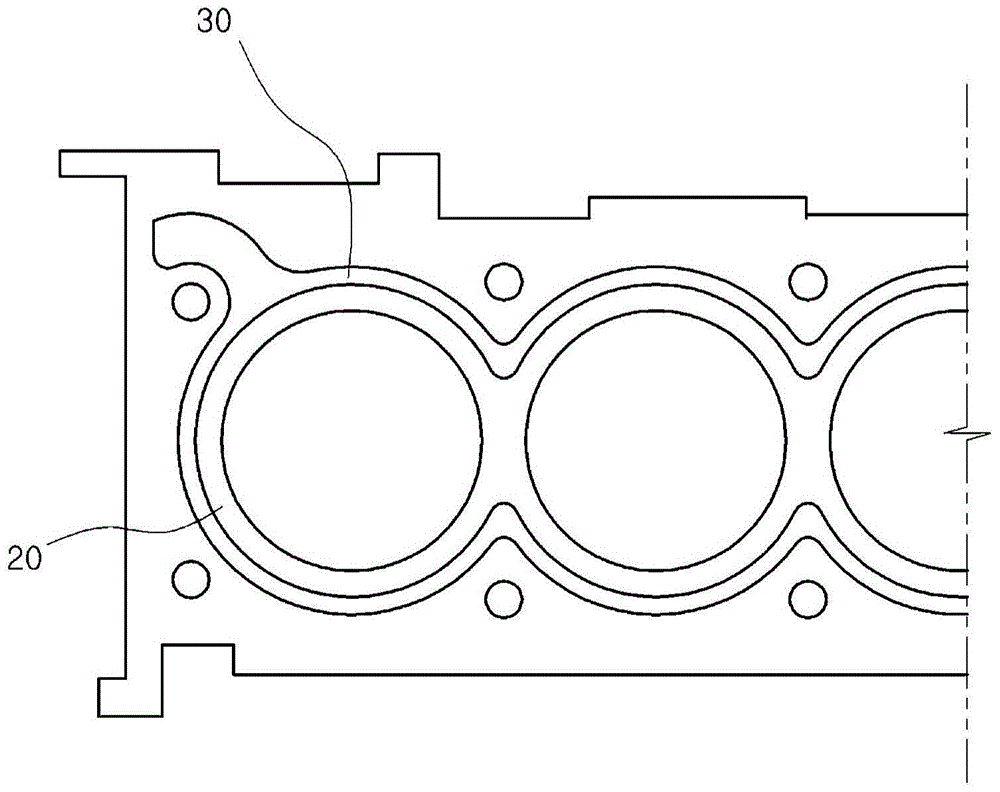

[0055] For the sake of convenience, the case of manufacturing an engine block unit including an aluminum engine block main body 10 and a cast iron bushing 20 by a die casting method will be described.

[0056] Since the die casting method is described in the background art, it will not be described repeatedly. The following description will focus on the features of the present invention.

[0057] A method for recovering a defective engine cylinder block in a continuous casting production line according to the present invention includes: inserting a hole pin 40 into an engine block mold M; assembling a real bush 20 on the outer peripheral surface of the hole pin 40; and melting aluminum It is injected into the engine block mold M to cast the engine block main body 10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com