Rotary main shaft device for micro electric spark machining machine

A technology of rotating spindle and spark machining, applied in electric machining equipment, accessories, metal machining equipment, etc., can solve the problems of complex and tiny device machining technology, and achieve the effect of improving machining quality, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

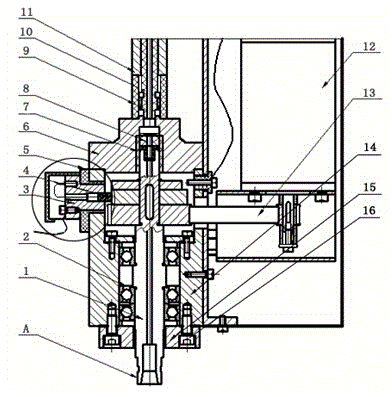

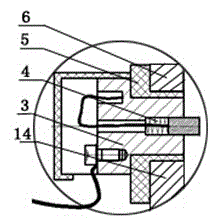

[0021] Referring to the accompanying drawings, a rotating spindle device of a micro electric discharge machine includes a rotating spindle 1, a precision bearing 2, an electrical device 3, a brush 4, an insulating plastic 5, an upper end cover 6, a first insulator 7, and a ceramic material 8 , the second insulator 9, the insulating inner tube 10, the outer casing of the liquid pipe 11, the motor 12, the timing belt 13, the main shaft casing 14, the lower end cover 15, the bolt 16, the motor 12 is installed on the bracket of the main shaft casing 14, and the timing belt 13 is one end Set on the output shaft of the motor 12, the other end is set on the pulley of the rotating main shaft 1, the second insulator 9 is installed on the upper end cover 6, the insulating inner tube 10 is installed in the second insulator 9, and the upper part of the second insulator 9 and the The outside of the insulating inner pipe 10 is installed with a liquid pipe outer casing 11, and the first insul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com