Diode pickling machine

A pickling machine and diode technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve problems such as large environmental pollution, strong corrosion, and large human injuries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

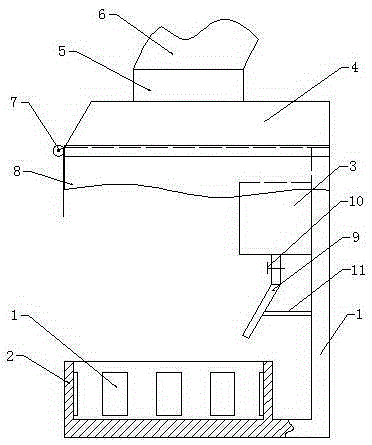

[0012] The reference signs in the drawings of the description include: bracket 1, pickling tank 2, acid tank 3, collecting cover 4, exhaust fan 5, exhaust pipe 6, rotating shaft 7, isolation cloth 8, liquid supply pipe 9, limiter Flow valve 10, strut 11.

[0013] The embodiment is basically as attached figure 1 Shown: diode pickling machine, including pickling tank 2, base, acid tank 3. The pickling tank 2 is located at the upper end of the base, and the inner wall of the pickling tank 2 is provided with a plurality of ultrasonic vibration plates. The base on one side of the pickling tank 2 is provided with a vertical support 1, and the acid tank 3 is fixed on the side of the support 1 close to the pickling tank 2, and the acid tank 3 is located at the side of the pickling tank 2 Above, the pickling tank 2, the base and the support 1 are integrally formed. A liquid su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com