Efficient and low-resistance electrospun nanofiber air filter material and batch preparation method

An air filter material and nanofiber technology, applied in the directions of electrospinning, chemical instruments and methods, separation methods, etc., can solve the problems of accelerating the surface charge dissipation of electret materials, attenuation of electret effect, and dissipation, etc., and achieve good results. Structural controllability, reducing filtration resistance, the effect of reducing filtration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

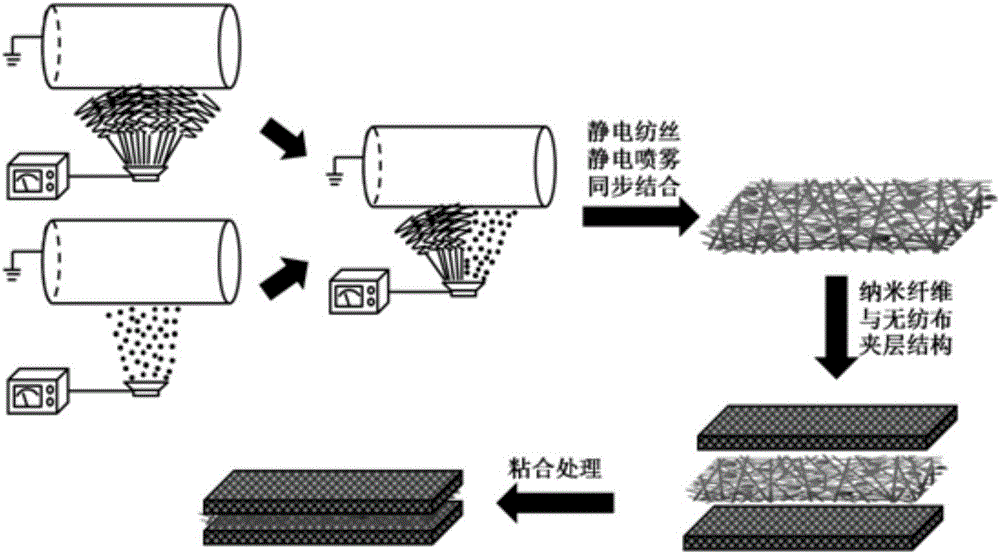

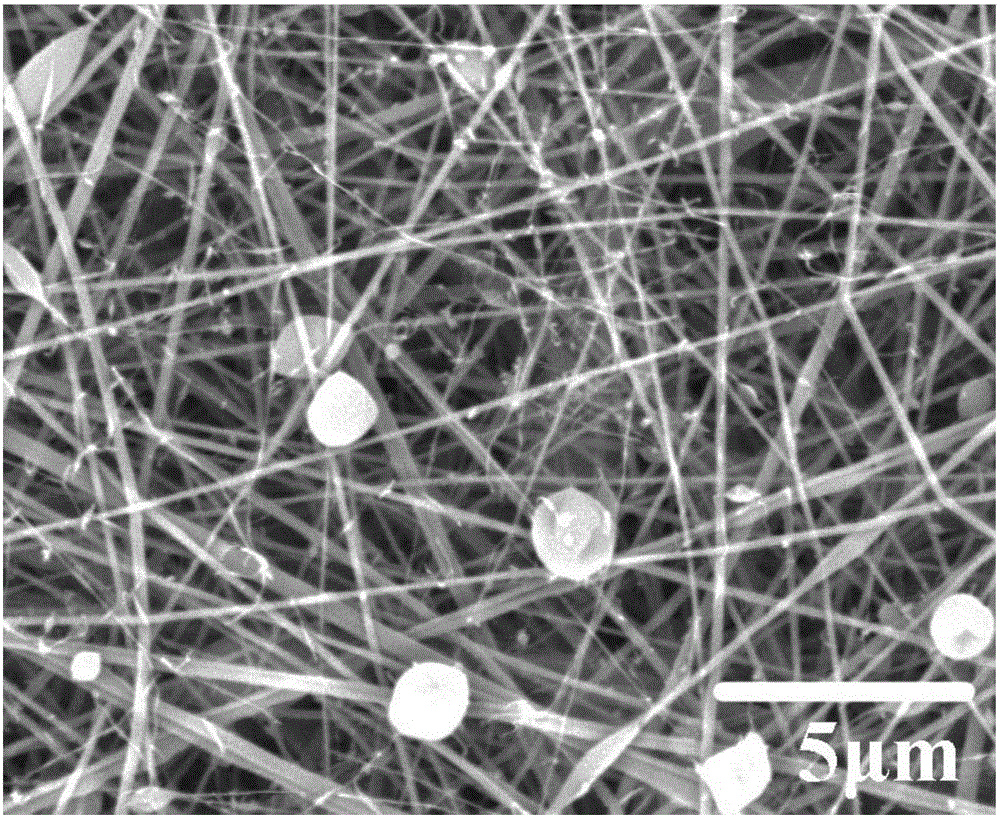

[0031]The filter material is a sandwich structure of spunbonded non-woven fabrics and nanofibers arranged alternately. The nanofibers are electrospun nanofiber / microsphere composite membranes. The structure of the electrospun nanofiber / microsphere composite membrane is: microspheres embedded in electrospun nanofibers The three-dimensional cavity structure formed between them; the diameter of the nanofiber is 139nm; the particle size of the microsphere is 658nm; the weight of the electrospun nanofiber / microsphere composite film is 1.08g / m 2 . The spunbonded nonwoven fabric used has a fiber diameter of 5 μm and a weight of 25 g / m 2 , The initial filtration efficiency of spunbond nonwovens is 0.2%.

[0032] A high-efficiency and low-resistance electrospun nanofiber air filter material and a batch preparation method, the specific steps are:

[0033] Step 1: Place the polyacrylonitrile powder in a vacuum drying oven and dry it under vacuum at 70°C for 8 hours;

[0034] Step 2: d...

Embodiment 2

[0040] The filter material is a sandwich structure of spunbonded non-woven fabrics and nanofibers arranged alternately. The nanofibers are electrospun nanofiber / microsphere composite membranes. The structure of the electrospun nanofiber / microsphere composite membrane is: microspheres embedded in electrospun nanofibers The three-dimensional cavity structure formed between them; the diameter of the nanofiber is 204nm; the particle size of the microsphere is 569nm; the weight of the electrospun nanofiber / microsphere composite film is 1.25g / m 2 . The spunbonded nonwoven fabric used has a fiber diameter of 5 μm and a weight of 30 g / m 2 , The initial filtration efficiency of spunbond nonwovens is 0.2%.

[0041] A high-efficiency and low-resistance electrospun nanofiber air filter material and a batch preparation method, the specific steps are:

[0042] Step 1: Place the polyacrylonitrile powder in a vacuum drying oven and dry it under vacuum at 70°C for 8 hours;

[0043] Step 2: ...

Embodiment 3

[0049] The filter material is a sandwich structure of spunbonded non-woven fabrics and nanofibers arranged alternately. The nanofibers are electrospun nanofiber / microsphere composite membranes. The structure of the electrospun nanofiber / microsphere composite membrane is: microspheres embedded in electrospun nanofibers The three-dimensional cavity structure formed between them; the diameter of the nanofiber is 236nm; the particle size of the microsphere is 631nm; the weight of the electrospun nanofiber / microsphere composite film is 1.96g / m 2 . The spunbonded nonwoven fabric used has a fiber diameter of 10 μm and a weight of 30 g / m 2 , The initial filtration efficiency of spunbond nonwovens is 0.1%.

[0050] A high-efficiency and low-resistance electrospun nanofiber air filter material and a batch preparation method, the specific steps are:

[0051] Step 1: Put the polyurethane particles in a vacuum drying oven and dry them under vacuum at 110°C for 8 hours;

[0052] Step 2: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com