A method for preparing functional reconstituted tobacco leaves with apple pomace

A technology for reconstituting tobacco leaves and apple pomace, applied in the directions of tobacco, application, treatment of tobacco, etc., can solve problems such as consumption of wood resources, and achieve the effects of reducing waste of resources, being beneficial to the protection of forest resources, and reducing the amount of tar released.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

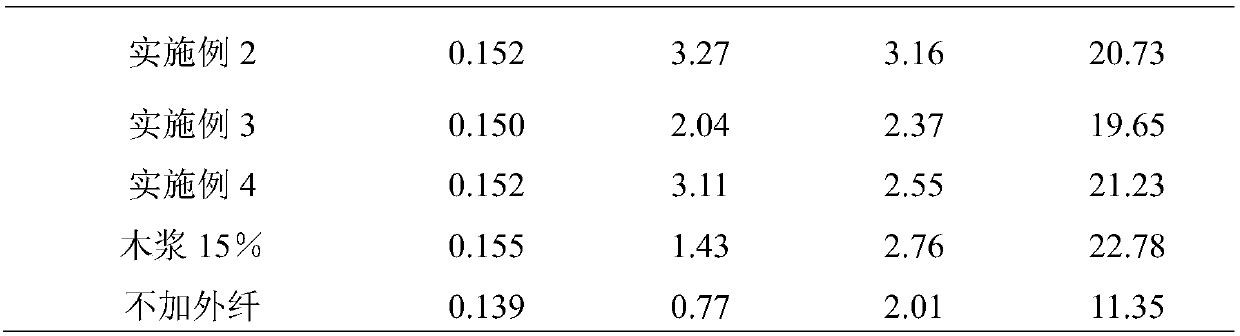

Examples

Embodiment 1

[0031] Step 1: add tobacco stems and tobacco leaf waste into hot water at 55°C for 50 minutes at a mass ratio of 1:1, the mass ratio of the mixture of tobacco stems and tobacco leaf waste to hot water is 1:6, and remove impurities from the extract After concentrating to obtain a concentrated solution with a concentration of 40%, the residue after extraction is subjected to refining treatment to obtain a beating degree of 32 ° SR tobacco slurry;

[0032] Step 2: Disperse and disperse the wet pomace produced online in the fruit juice factory into a fiber slurry with a mass concentration of 0.8%; then use a sieving machine to screen, remove impurities, dehydrate and concentrate to a mass concentration of 3%, and then use a fiber dissociator to carry out Step-by-step defrosting and grinding treatment, with a rotation speed of 2800r / min, to obtain pomace pulp with a beating degree of 55°SR, and a fiber length of 0.5mm to 1.5mm;

[0033] Step 3, performing medium-consistency refinin...

Embodiment 2

[0036] Step 1: add tobacco stems and tobacco leaf waste into hot water at 65°C for 40 min at a mass ratio of 1:1, the mass ratio of the mixture of tobacco stems and tobacco leaf waste to hot water is 1:7, and remove impurities from the extract After concentrating to obtain a concentrated solution with a concentration of 45%, the residue after extraction is subjected to refining treatment to obtain a beating degree of 34 ° SR tobacco slurry;

[0037] Step 2: Disperse and disperse the wet pomace produced online in the fruit juice factory into a fiber slurry with a mass concentration of 1.0%; then use a sieve machine to screen, remove impurities, dehydrate and concentrate to a mass concentration of 4%, and then use a fiber dissociator to carry out Step-by-step defrosting and grinding treatment, with a rotational speed of 2900r / min, to obtain pomace pulp with a beating degree of 60°SR, and a fiber length of 0.5mm to 1.5mm;

[0038] Step 3, performing medium-consistency refining on...

Embodiment 3

[0041] Step 1: add tobacco stems and tobacco leaf waste into hot water at 60°C for 50 minutes at a mass ratio of 1:1, the mass ratio of the mixture of tobacco stems and tobacco leaf waste to hot water is 1:6, and remove impurities from the extract After concentrating to obtain a concentration of 50% concentrated solution, the residue after extraction is subjected to refining treatment to obtain a beating degree of 28 ° SR tobacco slurry;

[0042] Step 2, soak the air-dried apple pomace for more than 2 hours, disperse and disperse it into a fiber slurry with a mass concentration of 0.9%; then use a sieve machine to screen, remove impurities, dehydrate and concentrate to a mass concentration of 4.5%, and then use a fiber dissociator to carry out Step-by-step defrosting and grinding treatment, with a rotational speed of 3000r / min, to obtain pomace pulp with a beating degree of 60°SR, and a fiber length of 0.5mm to 1.5mm;

[0043] Step 3, performing medium-consistency refining on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com