Anode material suitable for aqueous metal ion battery and preparation method for same

A technology of negative electrode material and metal ion, which is applied in the field of negative electrode material of water-based metal ion battery and its preparation, can solve the problem of less negative electrode material, and achieve the effects of good charging and discharging platform, large capacity and stable output voltage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

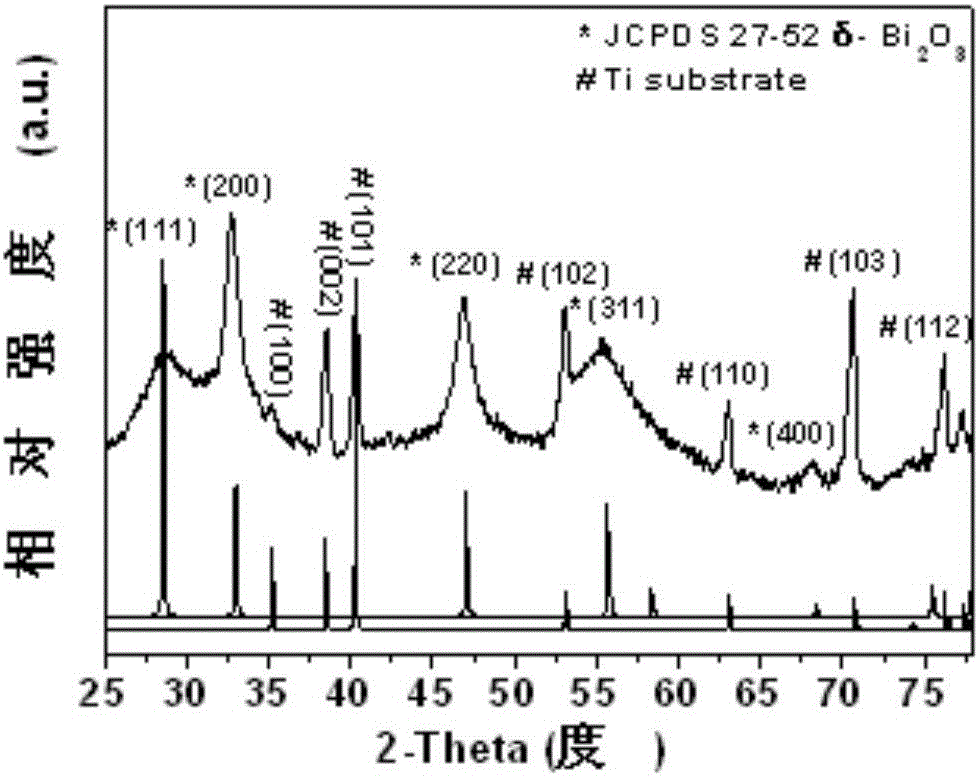

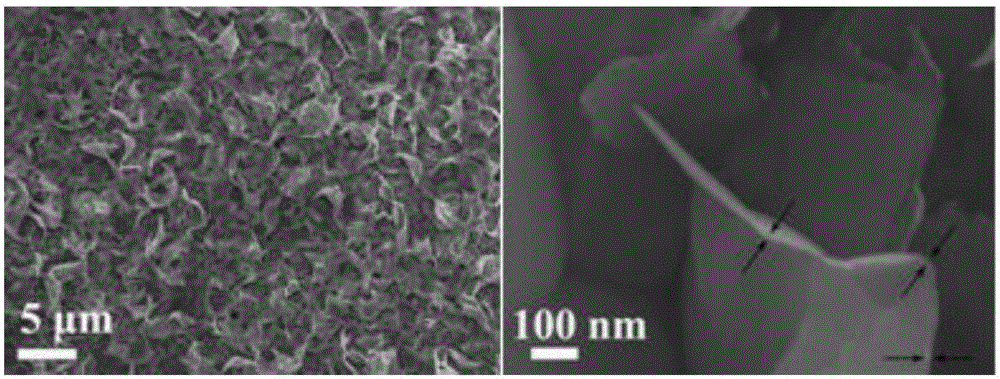

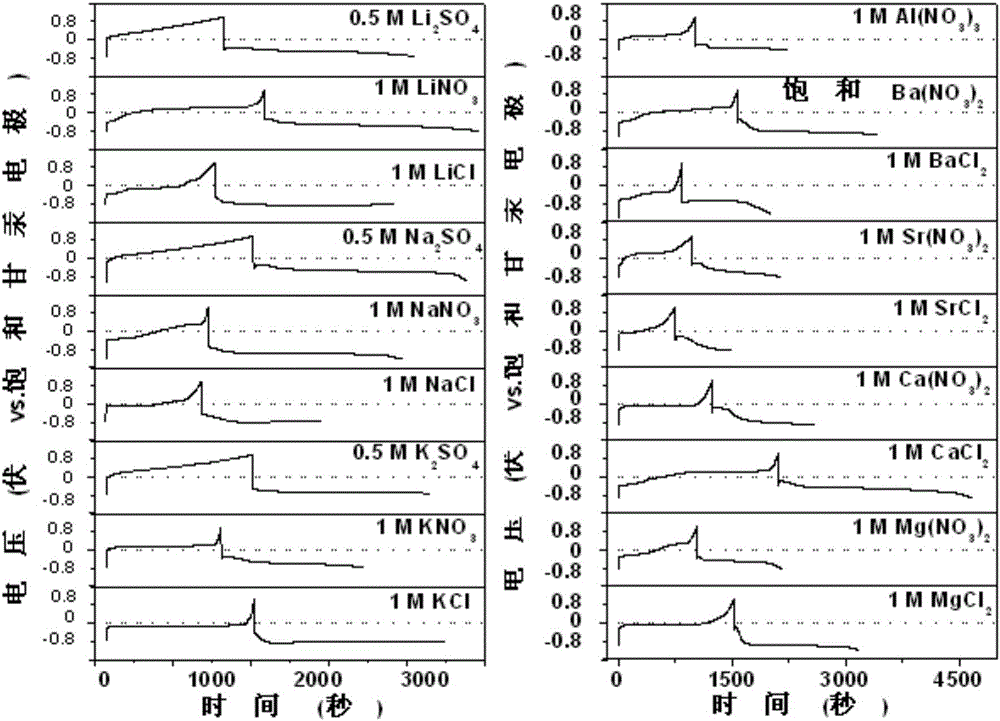

[0038] Preparation of negative electrode materials suitable for water-based metal-ion batteries: Stir 0.6g of bismuth nitrate pentahydrate, 6mL of ethylene glycol, and 12mL of acetone for 30 minutes as a bismuth-containing precursor solution, and put the cleaned titanium sheet with a thickness of 50 μm into the bismuth-containing Precursor solution, and placed in a 20mL polytetrafluoroethylene liner, then put the liner into a hydrothermal reaction vessel and seal it, and conduct a hydrothermal reaction at 160°C for 5 hours, then stop heating and cool to room temperature, and use ethanol and deionized water Rinse the residual solution on the surface of the sample, and grow a layer of bismuth oxide film on the surface of the titanium sheet current collector, which is suitable for the negative electrode material of the aqueous metal ion battery. The X-ray diffraction patterns of bismuth oxide thin films are shown in figure 1 , the scanning electron microscope image of the bismuth...

Embodiment 2

[0062] Preparation of negative electrode materials suitable for aqueous metal ion batteries:

[0063] 1) Preparation of bismuth oxide powder: Stir 0.6g of bismuth nitrate pentahydrate, 6mL of ethylene glycol, and 12mL of acetone for 30 minutes and place in a 20mL polytetrafluoroethylene liner, then put the liner into a hydrothermal reaction kettle and seal it. Hydrothermal reaction at 160°C for 5 hours, then stop heating and cool to room temperature, stir and wash the sample with ethanol and deionized water in a centrifuge, and dry to obtain nano-bismuth oxide powder;

[0064] 2) Preparation of negative electrode material: Add nano-bismuth oxide powder, carbon black and polyvinylidene fluoride (PVDF) to N-methylpyrrolidone solvent in a mass ratio of 8:1:1, and ball mill for 10 hours to prepare a slurry. Then the obtained slurry is uniformly coated on a thin titanium sheet with a thickness of 8 microns, baked at 120°C for 10 hours under vacuum, and finally pressed with a tablet...

Embodiment 3

[0068] Preparation of negative electrode materials suitable for water-based metal-ion batteries: Stir 0.6g of bismuth nitrate pentahydrate, 6mL of ethylene glycol, and 6mL of acetone for 30 minutes as a bismuth-containing precursor, put the cleaned titanium sheet into the bismuth-containing precursor, And put it in a 20mL polytetrafluoroethylene liner, then put the liner into a hydrothermal reaction kettle and seal it, and conduct a hydrothermal reaction at 120°C for 8 hours, then stop heating and cool to room temperature, and rinse the sample surface with ethanol and deionized water. A bismuth oxide film is grown on the surface of the titanium sheet current collector, which is suitable for the negative electrode material of the water-based metal ion battery. The scanning electron microscope image of the bismuth oxide film on the surface of the negative electrode material shows that the morphology of the obtained nano-bismuth oxide array film is similar to that of the nano-bism...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com