Full-spectrum CSP packaging light source and manufacturing method thereof

A full-spectrum, light source technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of low luminous efficiency of monochromatic chips, difficult to adjust spectral characteristics, unable to present full spectrum, etc., to achieve excellent light quality, High saturation, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

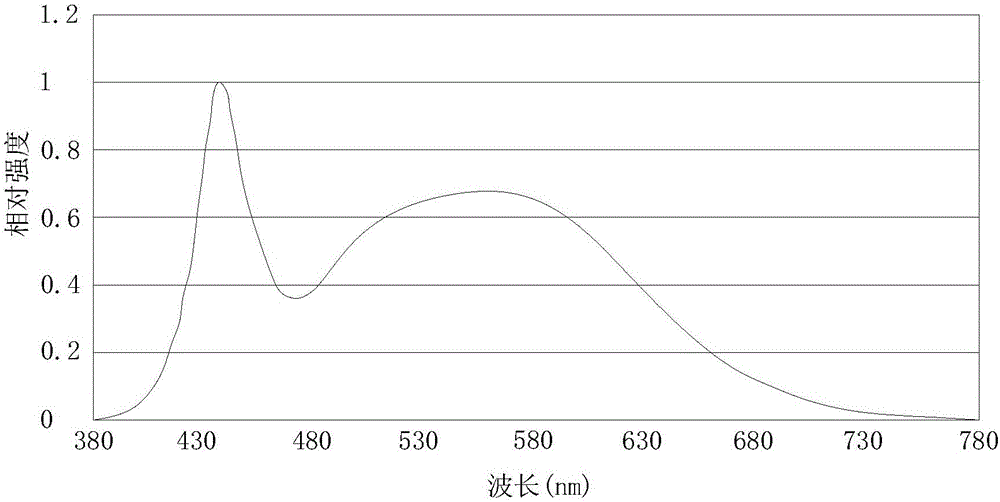

Embodiment 1

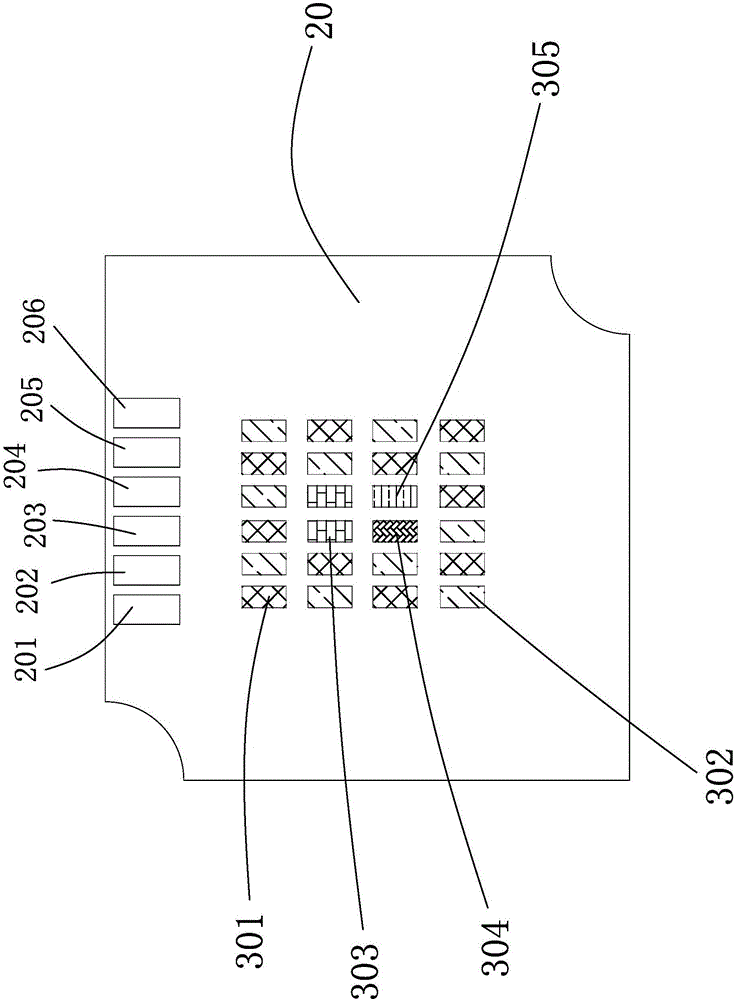

[0046] Such as figure 2 shown ( figure 2 The area filled in is not a cross-sectional area, the filling is just to distinguish different CSP light sources), in this embodiment, the package bracket is the substrate 20 with six electrodes, and the six electrodes are the first electrode 201, the second electrode 202, the third electrode 203, the fourth electrode 204, the fifth electrode 205 and the sixth electrode 206, the first electrode 201 is used as the positive electrode of the substrate, and the other five electrodes are used as the negative electrode of the support, and the high color temperature white light CSP light source 301 There are 10 low color temperature white light CSP light sources 302 each, 2 green light CSP light sources 303 with an emission wavelength of 460-500nm, and 1 green CSP light source 304 with an emission wavelength of 520-580nm, with an emission wavelength of 600nm -700nm red light CSP light source 305 is provided with one, blue light CSP light so...

Embodiment 2

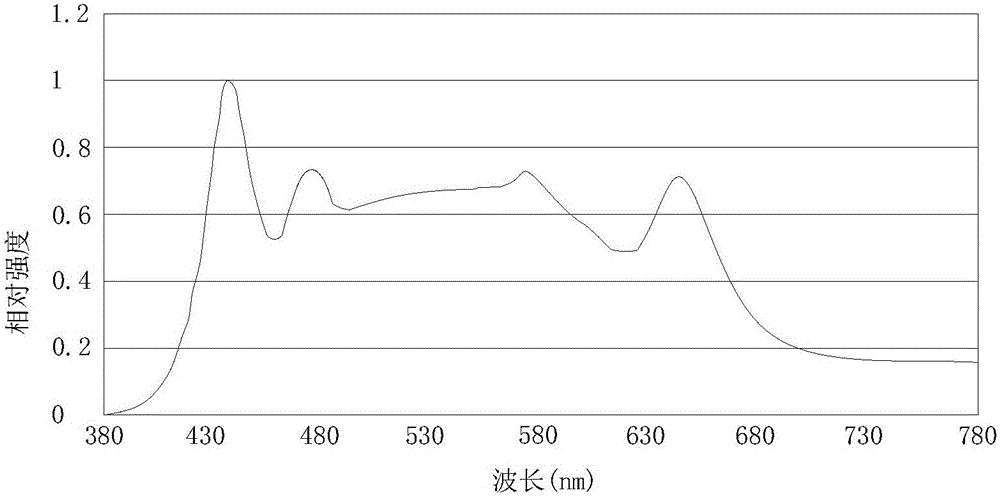

[0053] The structure of this embodiment is roughly the same as that of Embodiment 1, the only difference is: in this embodiment, there are 12 high-color-temperature white light CSP light sources 301 and 12 low-color-temperature white light CSP light sources 302 each, and the output wavelength is 460-500nm. There are 4 green light CSP light sources 303, 2 green light CSP light sources 304 with an emission wavelength of 520-580nm, 3 red light CSP light sources 305 with an emission wavelength of 600-700nm, blue light CSP light sources 303, The green CSP light source 304 and the red CSP light source 305 are arranged on the substrate to form a circular supplementary light source area, and the arrays of high color temperature white light CSP light source 301 and low color temperature white light CSP light source 302 are alternately packaged on the substrate 20 outside the supplementary light source area to form Circular primary light area. Its spectrum is as Figure 5 As shown, the...

Embodiment 3

[0055] The structure in this embodiment is roughly the same as that in Embodiment 1, the only difference is that in this embodiment, there are 15 high-color-temperature white light CSP light sources 301 and 15 low-color-temperature white light CSP light sources 302 each, and the output wavelength is 460-500nm. There are 7 blue light CSP light sources 303, 5 green light CSP light sources 304 with an emission wavelength of 520-580nm, 7 red light CSP light sources 305 with an emission wavelength of 600-700nm, blue light CSP light sources 303, The green CSP light source 304 and the red CSP light source 305 are arranged on the substrate to form a hexagonal supplementary light source area, and the high color temperature white light CSP light source 301 and the low color temperature white light CSP light source 302 arrays are alternately packaged on the substrate 20 outside the supplementary light source area Forms a hexagonal main light source area. Its spectrum is as Figure 6 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com