Opening and closing coil control circuit of long stroke permanent magnet mechanism

A technology of opening and closing coil and permanent magnet mechanism, applied in the direction of protection switch operation/release mechanism, etc., can solve the problems of large closing bounce and opening bounce, large starting current, low opening speed, etc. The effect of brake bounce, reducing starting current and increasing opening and closing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

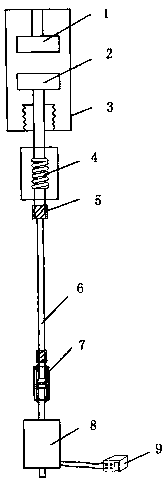

[0011] The present invention is described in detail below in conjunction with accompanying drawing:

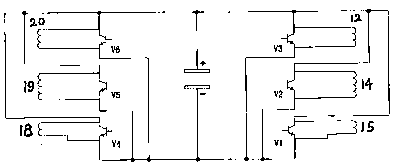

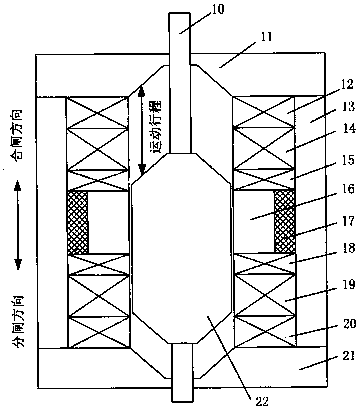

[0012] An opening and closing coil control circuit of a long-stroke permanent magnet mechanism, comprising a DC power supply, a thyristor control circuit, a first closing coil 15, a second closing coil 14, a third closing coil 12, and a first opening coil 18 , the second opening coil 19, the third opening coil 20, the first thyristor thyristor V1, the second thyristor thyristor V2, the third thyristor thyristor V3, the fourth thyristor thyristor V41, the fifth thyristor SCR thyristor V5 and sixth SCR thyristor V6, the collector of the first SCR thyristor V1, the collector of the second SCR thyristor V2, the collector of the third SCR thyristor V3, the fourth SCR thyristor The collector of the silicon controlled thyristor V4, the collector of the fifth silicon controlled thyristor V5 and the collector of the sixth silicon controlled thyristor V6 are all connected to the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com