Preparation of uneven humid efficient phase changing coating and gravity assisted heat pipe device

A gravity heat pipe and wettability technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of affecting heat transfer effect, difficulty in detaching air bubbles, performance deterioration, etc., and achieve the goal of simplifying the processing process and saving material costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

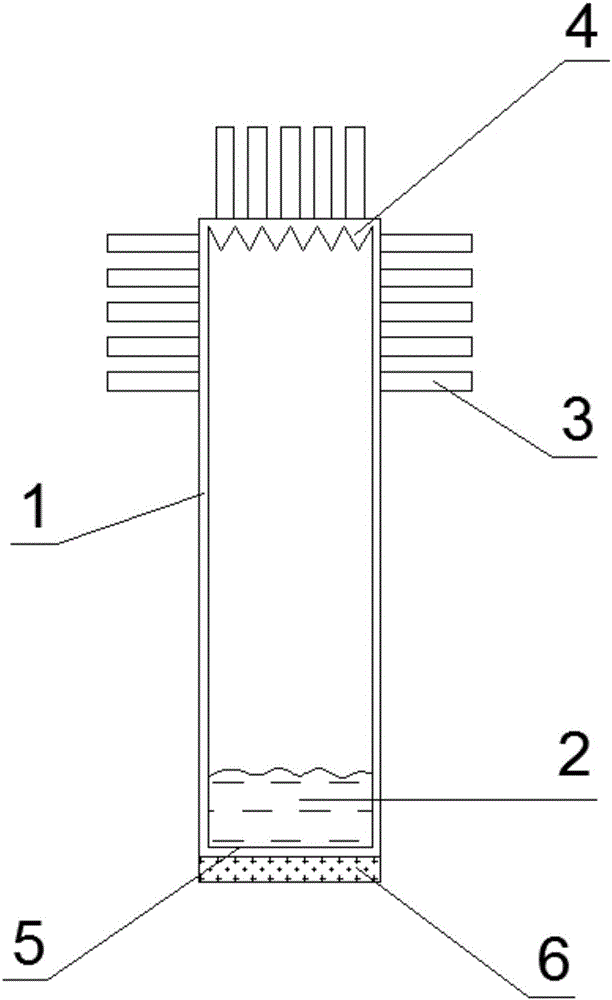

[0045] Such as Figures 1 to 3 shown. The invention discloses a gravity heat pipe device with non-uniform wettability and high-efficiency phase change coating, which comprises a pipe body 1 with both ends sealed, and a liquid working medium 2 is poured into the pipe body 1;

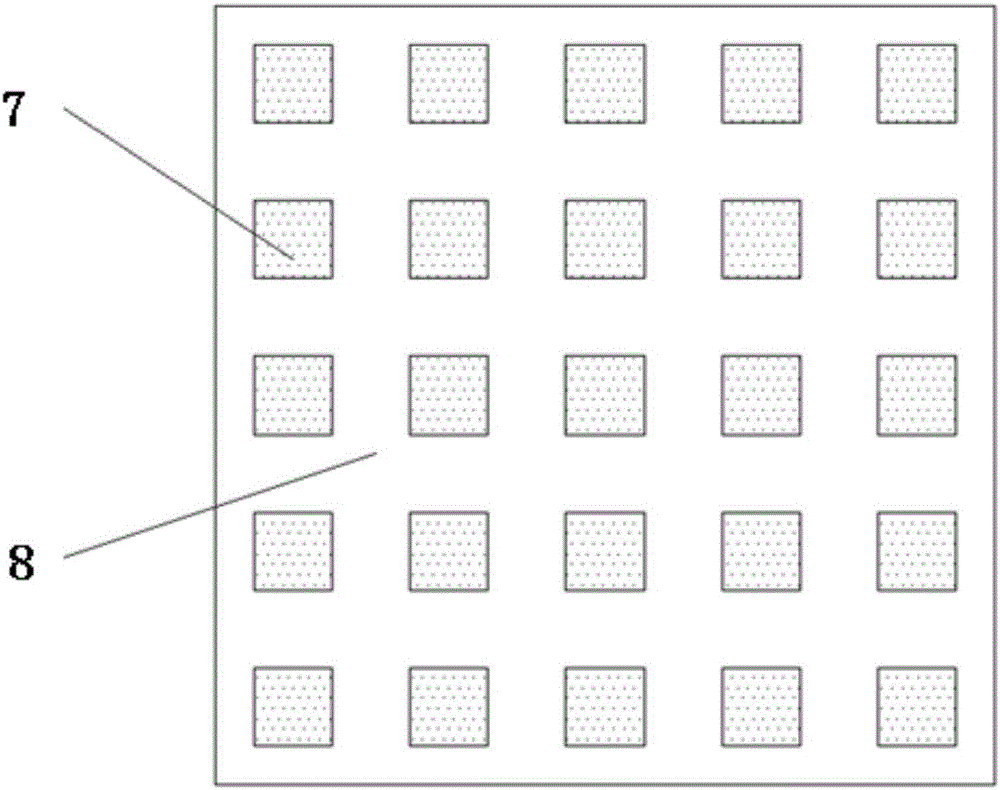

[0046] The upper part of the pipe body 1 is the condensing section, and the lower part is the evaporating section; the inner top wall of the condensing section is a serrated structural surface 4; the inner wall of the condensing section, the serrated structural surface 4 and the inner bottom surface of the evaporating section are all covered with non-uniform Wettability coating; non-uniform wettability coating comprising hydrophobic regions 7 and hydrophilic regions 8 .

[0047] The structure of the non-uniform wettability coating covering the bottom surface in the evaporation section is square, circular or triangular. Of course, it can also be in other shapes, which can be determined according to speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com