Torsional axial rotary dynamic vibration absorber

A dynamic shock absorber, axial technology, applied in the direction of shock absorber, friction shock absorber, spring/shock absorber, etc., can solve the problem of dynamic imbalance of the system, and achieve the effect of reducing dynamic imbalance and good dynamic balance , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following embodiments will describe the present invention in detail with reference to the accompanying drawings.

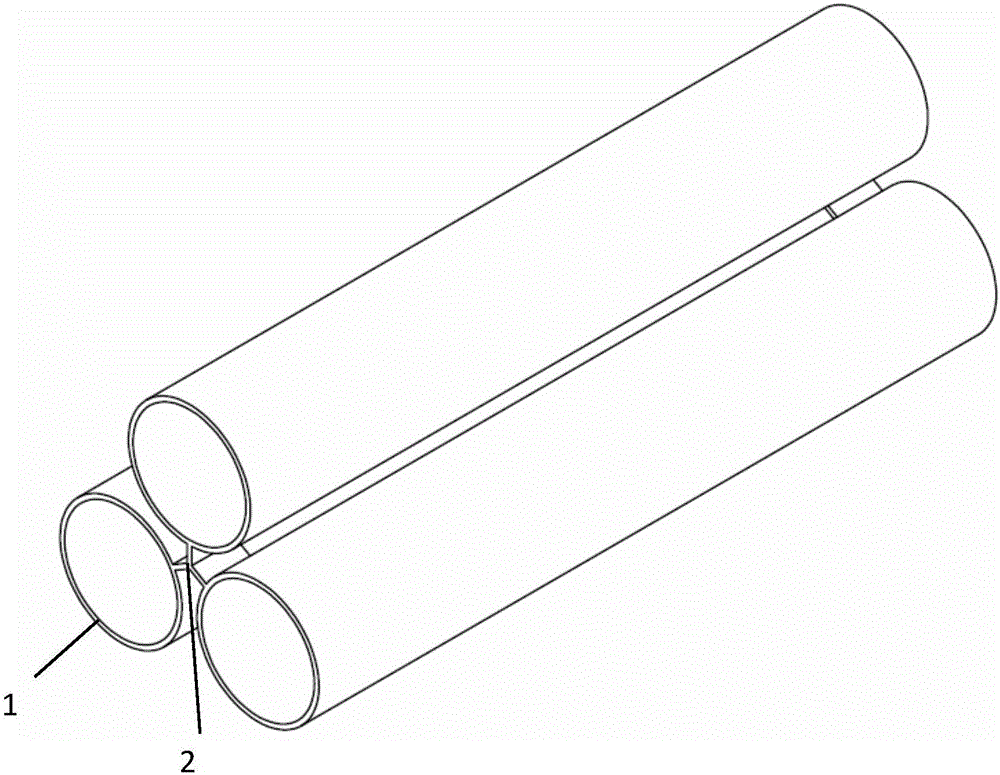

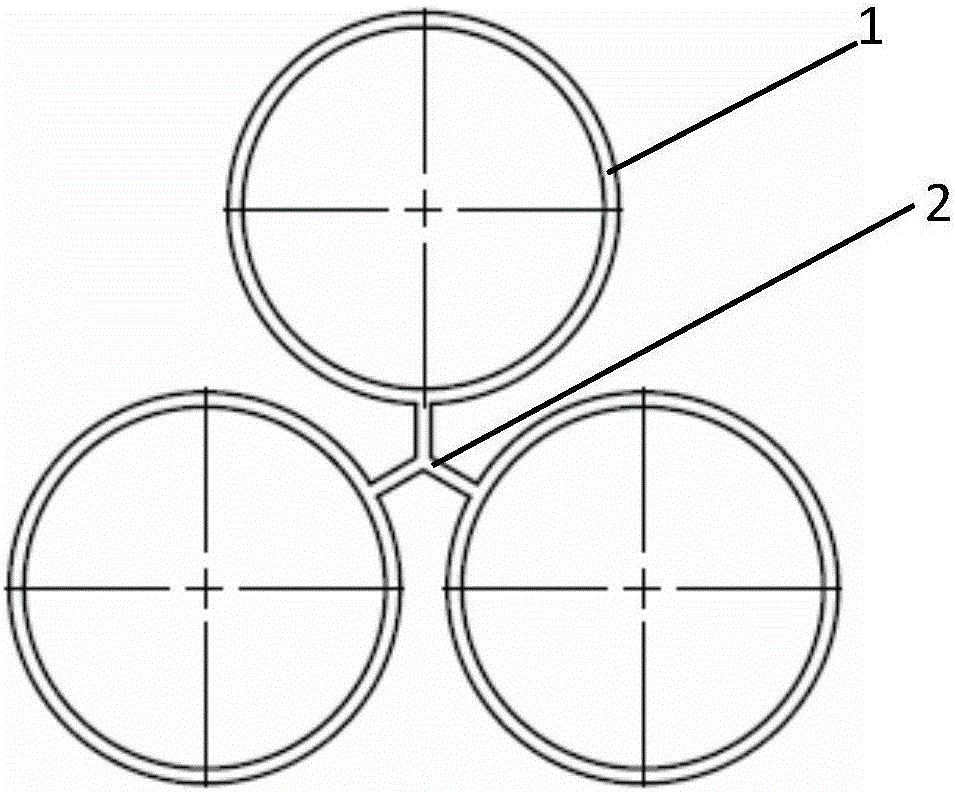

[0034] see Figure 1-14 , the embodiment of the present invention is provided with three shaft tubes 1, the three shaft tubes 1 are fixed by ribs 2, the two ends of the three shaft tubes 1 are provided with fixed cover plates 3, and the three shaft tubes 1 are filled with particles 4 .

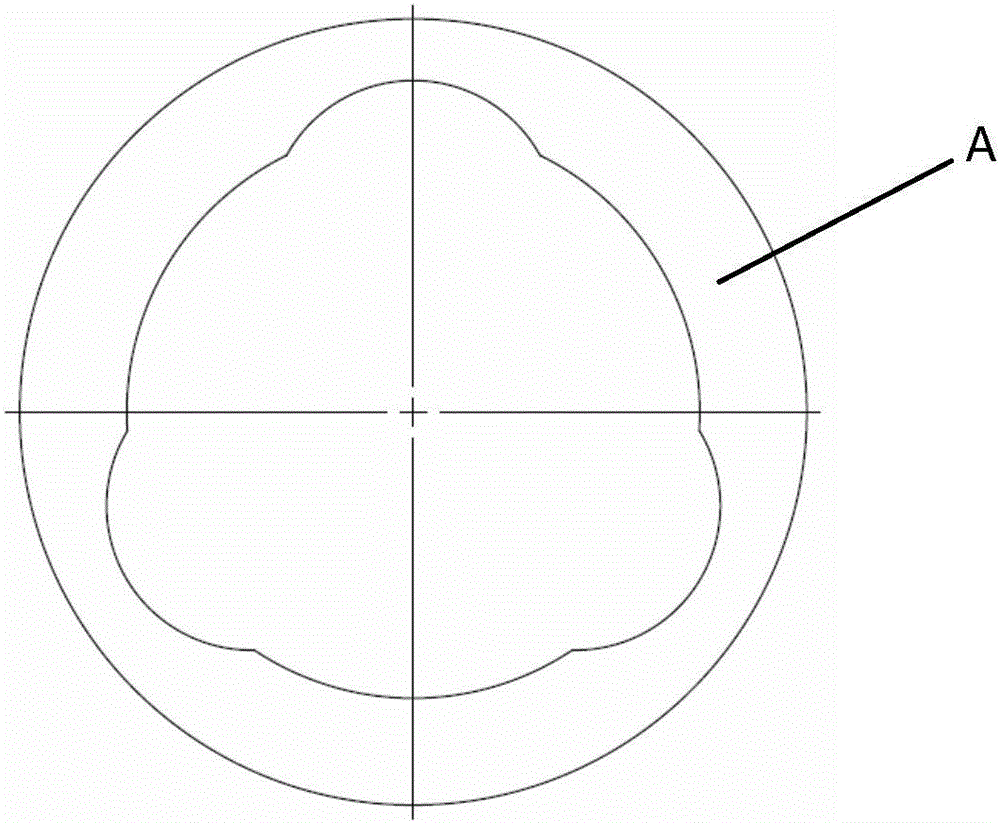

[0035] The shaft tube 1 can be a circular tube, and the three shaft tubes preferably have the same length and diameter.

[0036] The ribs 2 can be arranged between the outer walls of the shaft tube.

[0037] The size, material and number of particles 4 filled in the shaft tube 1 are preferably the same.

[0038] The fixed cover plate 3 can be screwed to both ends of the shaft tube 1 through threads.

[0039] The shaft tube 1 is preferably divided into 2-6 sections in the axial direction.

[0040] When in use, the outer wall of the shaft tube is in transition fit wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com