A coal-friendly base gas drainage drilling hole sealing material and its application method

A technology for gas extraction and hole sealing materials, which is applied in the directions of gas discharge, drilling compositions, chemical instruments and methods, etc., can solve the problems of poor sealing effect, low strength and high reaction temperature, and achieve good flame retardant resistance. Effects of electrostatic properties, high compressive strength and strong coal affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

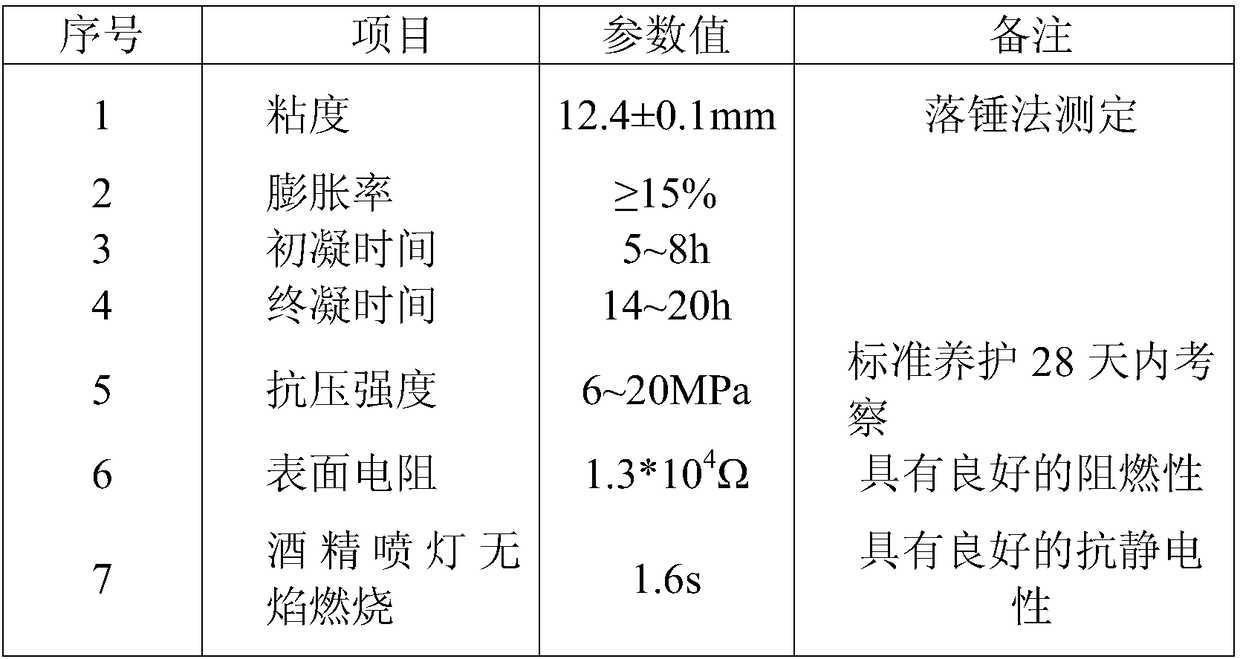

Image

Examples

Embodiment 1

[0012] P·I425(R) Portland cement 53%, Class II fly ash 8%, calcium sulfate 8%, calcium carbonate 20%, silicon dioxide 8%, methyl cellulose 0.2%, water reducer 1%, Iron powder 0.8%, aluminum powder 0.8%, oxalic acid 0.2%.

Embodiment 2

[0014] P·P425(R) Pozzolanic Portland Cement 50%, Class II Fly Ash 10%, Calcium Sulfate 9%, Calcium Carbonate 19%, Silicon Dioxide 9%, Methylcellulose 0.1%, Water Reducer 1 %, iron powder 0.8%, aluminum powder 0.9%, oxalic acid 0.2%.

Embodiment 3

[0016] P·O42.5(R) Ordinary Portland cement 50%, Class I fly ash 8%, Calcium sulfate 9%, Calcium carbonate 20%, Silicon dioxide 9%, Methyl cellulose 0.2%, Water reducer 1.5%, iron powder 1%, aluminum powder 1%, oxalic acid 0.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com