Sludge treatment method and electrochemical appliance

A treatment method, electrochemical technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve limited EPS degradation ability, secondary pollution, and reduce compressibility and other problems, to achieve the effect of deep dehydration, enhanced cracking effect, and enhanced sludge strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

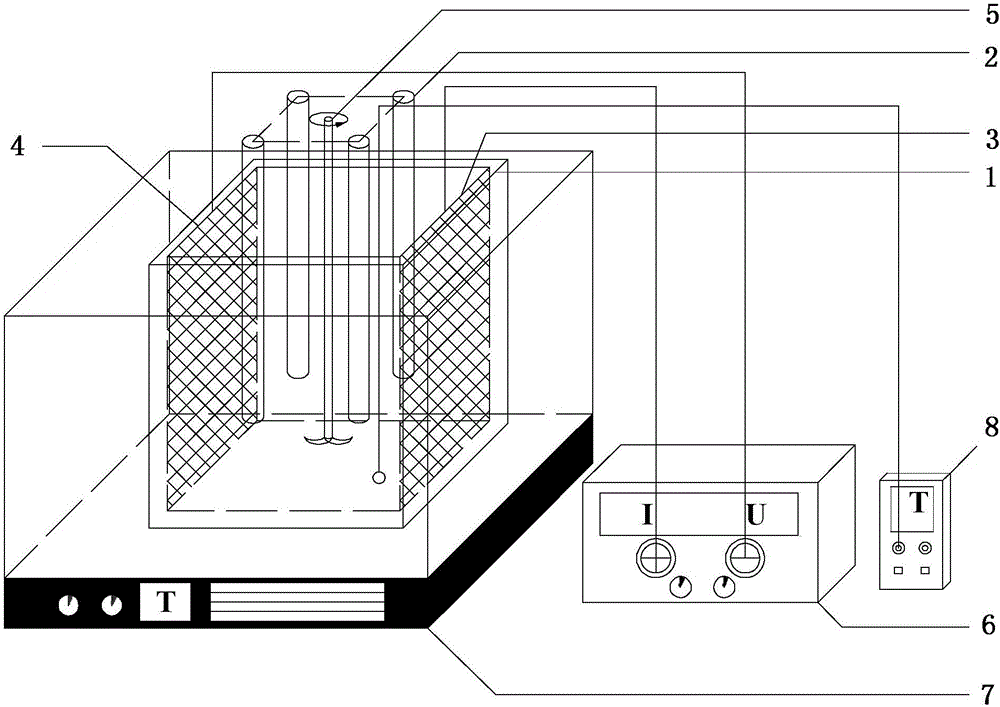

[0047] An electrochemical device, see figure 1 , including a DC power supply 6, an electrolytic cell 1 and an iron rod 2, the electrolytic cell 1 is provided with an anode plate 3 (IrO 2 -RuO 2 / Ti electrode plate) and cathode plate 4 (Ti electrode plate), IrO 2 -RuO 2 The / Ti electrode plate is connected in series with the positive pole of the DC power supply 6; the Ti electrode plate is connected in series with the negative pole of the DC power supply 6 to form a current loop. Iron rod 2 is set in IrO 2 -RuO 2 / Between the Ti electrode plate and the Ti electrode plate.

[0048] Preferably, the distance between the anode plate and the cathode plate is 120mm.

[0049] Preferably, there are four iron rods 2, and the four iron rods 2 are arranged between the anode plate 3 and the cathode plate 4 in a square arrangement, and the distance between each iron rod 2 and the center of the square is 30 mm. The centers of the four iron rods 2 coincide with the centers of the anod...

Embodiment 2

[0054] A method for treating sludge, comprising the steps of:

[0055] (1) The remaining sludge was taken from a sewage plant in Changsha City. After standing for 12 hours, the moisture content of the sludge was 96.0%-96.9%, and the pH of the sludge was 6.80.

[0056] (2) Add sodium persulfate accounting for 11.2% of the dry weight of the sludge to the sludge in step (1) at a stirring rate of 200 r / min, and stir for 5 minutes to obtain a mixture.

[0057] (3) The mixture of step (2) is dropped into the electrolytic cell 1 of the electrochemical device (ie the electrochemical device of embodiment 1), and the submerged depth of four iron rods 2 in the sludge in the electrolytic cell 1 is 30mm.

[0058] (4) Turn on the DC power supply 6 of the electrochemical device and the power supply of the mechanical stirrer 5, and conduct the electrification treatment on the mixture in step (2) for 20 minutes at a stirring rate of 200 r / min and a voltage of 40 V.

[0059] (5) Close the DC p...

Embodiment 3

[0063] A method for treating sludge, comprising the steps of:

[0064] (1) The remaining sludge was taken from a sewage plant in Changsha City. After standing for 12 hours, the moisture content of the sludge was 96.0%-96.9%, and the pH of the sludge was 6.80.

[0065] (2) Add sodium persulfate accounting for 11.2% of the dry weight of the sludge to the sludge in step (1) at a stirring rate of 200 r / min, and stir for 5 minutes to obtain a mixture.

[0066] (3) the mixture of step (2) is dropped into the electrolytic cell 1 of the electrochemical device (i.e. the electrochemical device of embodiment 1), and the submerged depth of four iron rods 2 in the electrolytic cell 1 is 30mm in the sludge .

[0067] (4) Turn on the DC power supply 6 of the electrochemical device and the power supply of the mechanical stirrer 5, and conduct the electrification treatment on the mixture in step (2) for 20 minutes at a stirring rate of 200 r / min and a voltage of 40 V.

[0068] (5) Close the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com