Composite biological filter material for biological aeration filter tanks

An aerated biological filter and biological filter material technology, applied in sustainable biological treatment, biological water/sewage treatment, water pollutants, etc., can solve problems such as environmental pollution, unfavorable seawater recycling, etc. Conducive to hanging film and ensure the effect of filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0037] A composite biological filter material for biological aerated filter, characterized in that: it includes a cylindrical shell made of carbon fiber, the shell is provided with 1-3 coaxial diameter gradually reduced Cylindrical inner core, between the shell and the inner core and between the inner core and the inner core are provided with a plurality of connecting walls radially connected and made of carbon fiber; the cylindrical inner core (2) It is made of composite material, and the composite material is mainly prepared from the following components according to the following parts by mass: 45-55 parts of epoxy resin, 55-65 parts of glass fiber and 0.05-1 part of tea polyphenol extract;

[0038] The mass ratio of described epoxy resin and glass fiber is preferably 50:55;

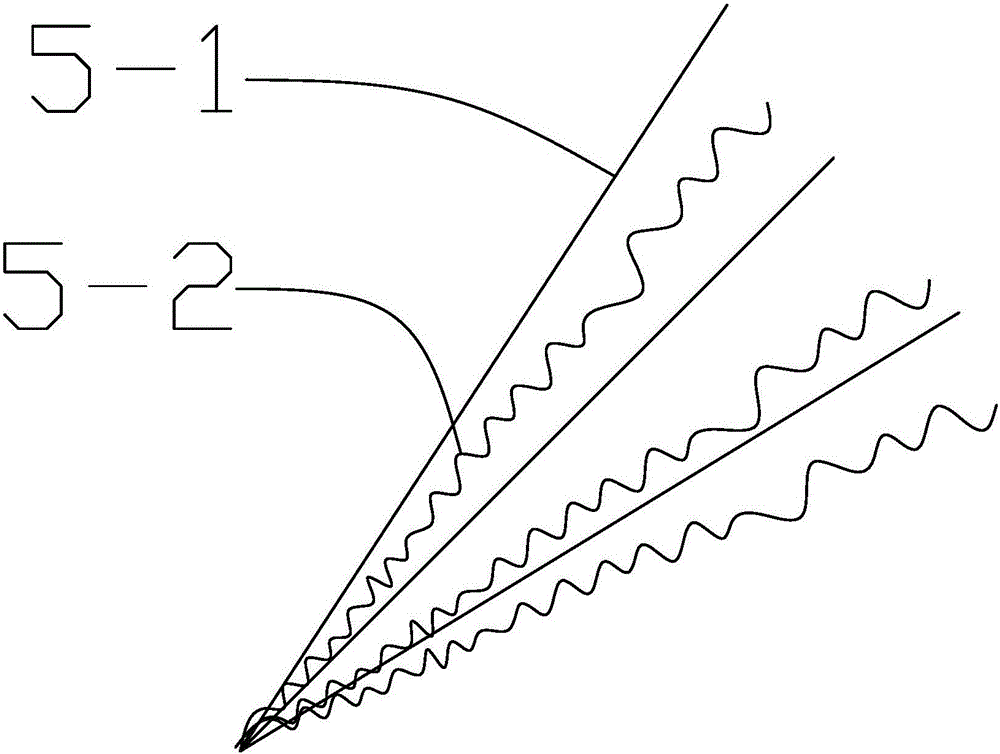

[0039] The outer wall of the casing is provided with a plurality of first fiber tows 4 extending outward, and the two sides of each connecting wall 3 are respectively provided with a plurality of seco...

Embodiment 1

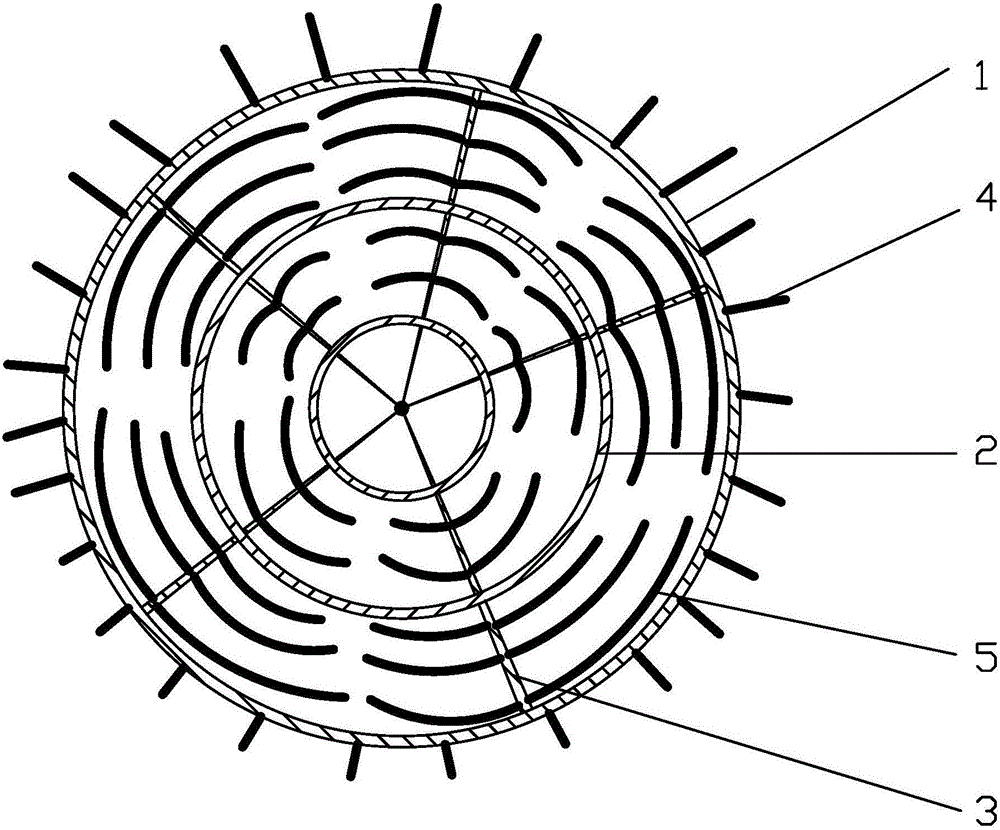

[0064] Such as figure 1 As shown, a composite biological filter material for biological aerated filter is characterized in that it includes a cylindrical shell made of carbon fiber, and two coaxial diameters are gradually reduced in the shell. The cylindrical inner core, the cylindrical inner core is made of composite material, and the composite material is mainly prepared from epoxy resin, glass fiber and tea polyphenol according to the mass ratio of 45:55:1 The composite material, between the shell and the inner core and between the inner core and the inner core is provided with a plurality of connecting walls radially connected and made of carbon fibers;

[0065] The outer wall of the housing is provided with a plurality of first fiber bundle connecting walls 4 extending outward, and each connecting wall 3 is provided with a plurality of second fiber bundles extending in the direction of the adjacent connecting wall 3 on both sides. bundle 5.

[0066] The carbon fiber she...

Embodiment 2

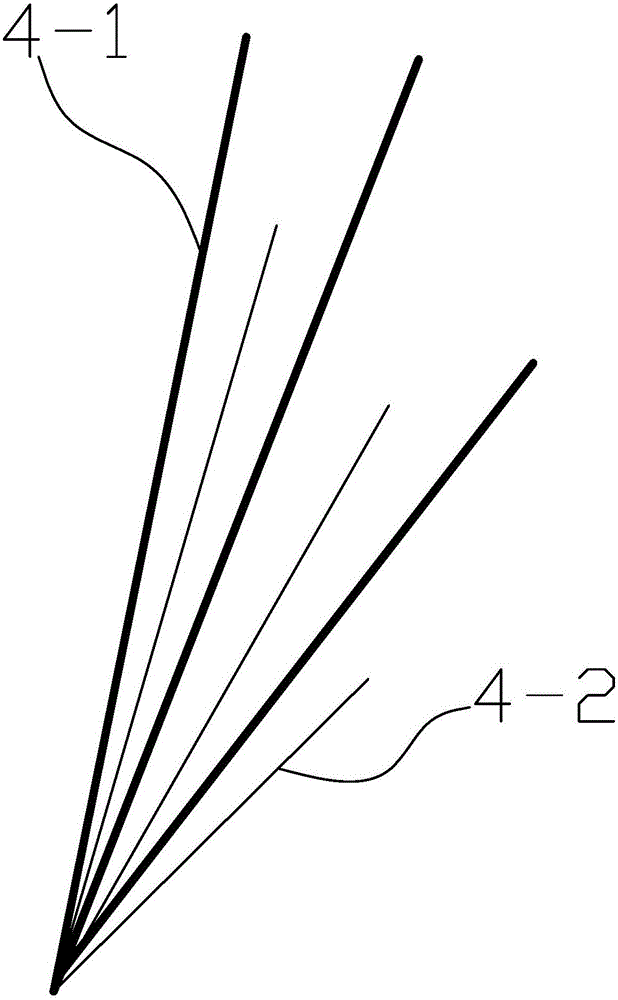

[0069] Such as figure 2 As shown, the first fiber tow 4 and the second fiber tow 5 are composed of a plurality of carbon fiber filaments 4-2 connecting walls of different lengths and acrylic fiber filament connecting walls 4-1 connecting walls staggered distribution, wherein The diameter of the acrylic fiber filament is 0.5-0.8 mm, and the diameter of the carbon fiber filament is 8-10 microns.

[0070] Adopting the above-mentioned technical scheme can maintain a high porosity for a long time, and at the same time increase the contact between filter materials, thereby increasing the contact between microorganisms, so that the dispersion is more uniform, and the ammonia nitrogen and nitrite can be decomposed more effectively , and the use of fiber filaments of different diameters can prevent the filter materials from being compacted. The expanded area of 1 kilogram of filter material in this embodiment is greater than 300m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com