Side feeding spiral type continuous extrusion blow molding die head

An extrusion blow molding and spiral technology, which is applied in the field of side-feed spiral continuous extrusion blow molding die, can solve the problems of easy cracking of weld lines and failure to drop test, etc., and achieves good outer surface finish, uniform texture, high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with the embodiment shown in the accompanying drawings, the present invention is described in detail as follows:

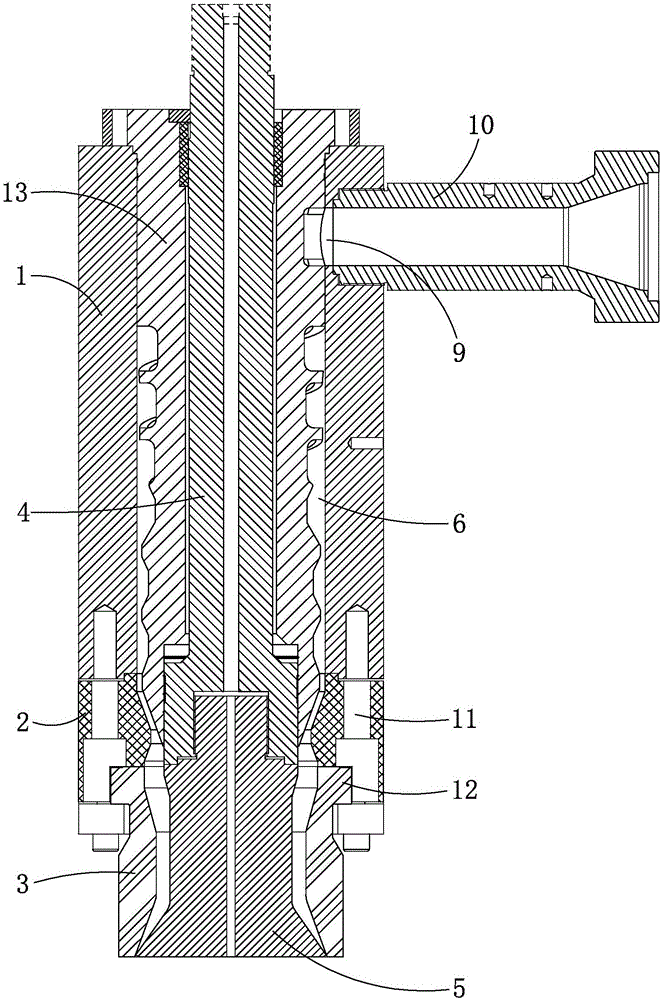

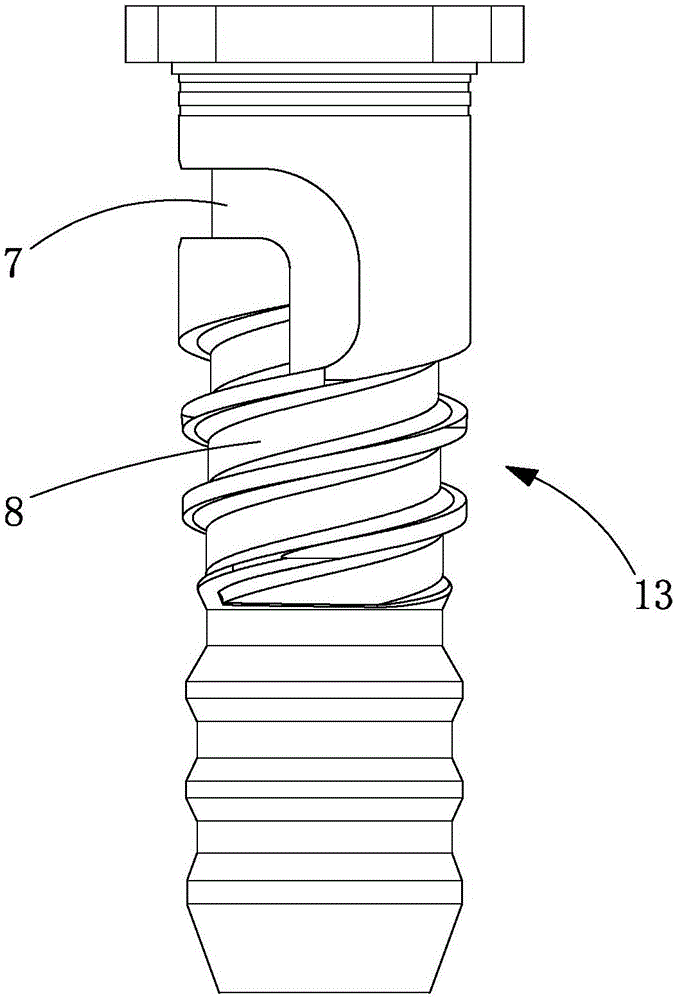

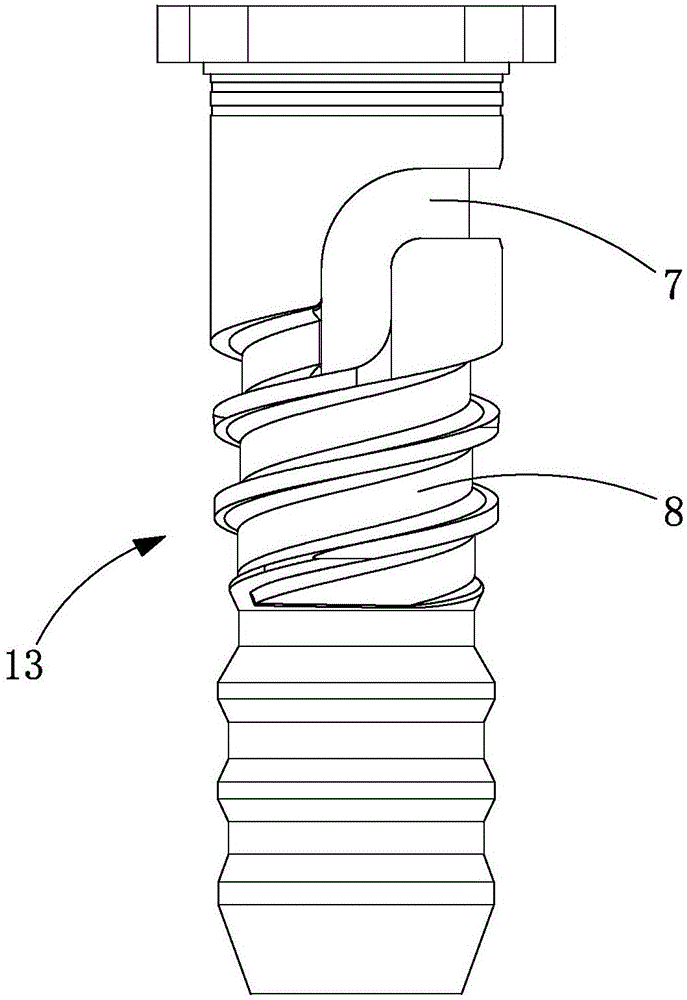

[0018] as attached figure 1 to attach image 3 As shown, a side-feed spiral continuous extrusion blow molding die head includes an outer layer structure and an inner layer structure. The outer layer structure includes an outer mold sleeve 1, an adjusting ring 2 and a mouthpiece that are sequentially connected and installed axially. Die 3, the inner layer structure includes the lifting rod 4 and the mandrel 5 that are axially connected and installed, and the outer mold cover 1, the adjusting ring 2 and the die 3 are all hollow structures in the shaft. The lifting rod 4 is received in the outer mold sleeve 1 and the adjusting ring 2, the mandrel 5 is received in the die 3, and the outer peripheral wall of the lifting rod 4 is sleeved There is a flow-distributing spiral core 13 that can move relatively axially, and a material flow channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com