Precision seamless spinning base flat belt and preparation method thereof

A flat-based, seamless technology, applied in textiles and papermaking, knitting, weft knitting, etc., can solve problems that do not involve adhesives and glue, save raw materials, reduce costs, protect the environment, and avoid subsequent joints Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

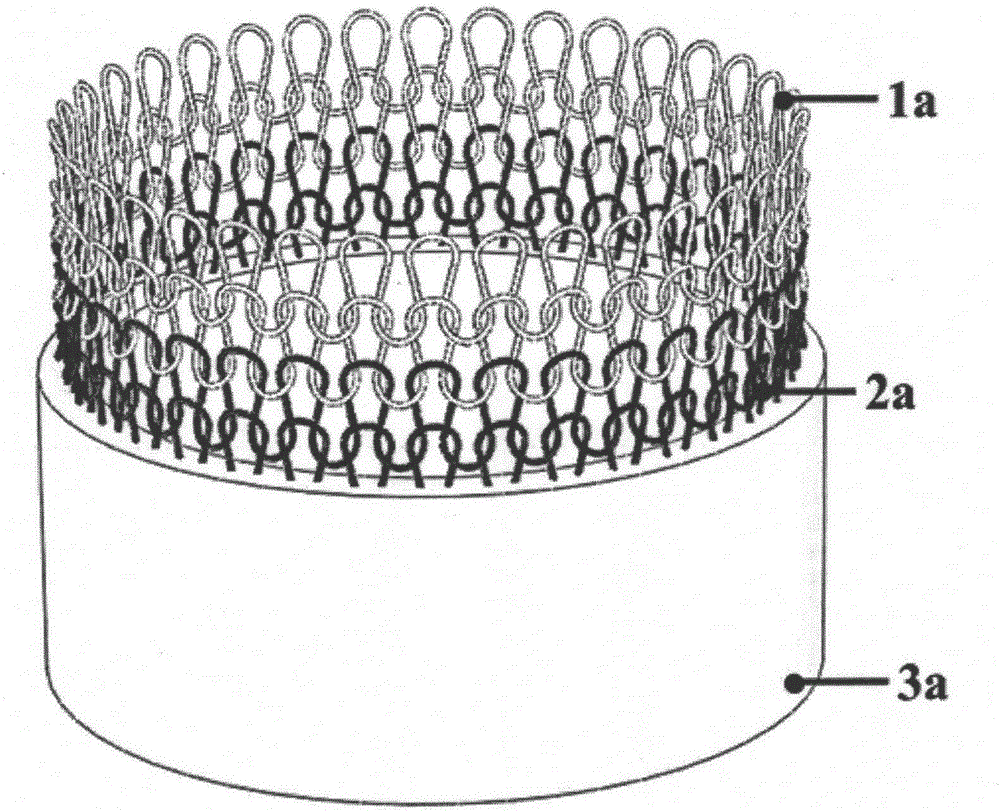

[0037] A preparation method of precision seamless textile base flat belt:

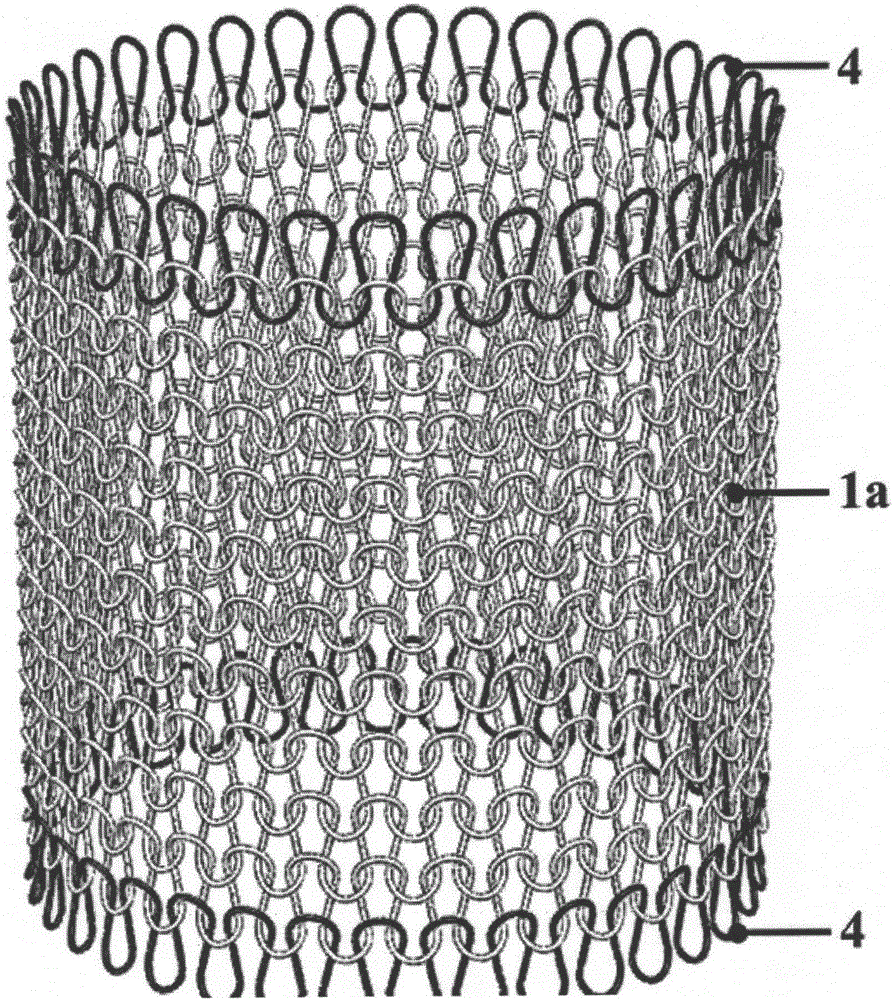

[0038] Step 1: Use 180D / 24F high-linear density and high-elasticity polyester multifilament to weave one end anti-spray edge sealing structure 4 on a custom-made circular knitting machine, the length of which is 10cm, and then replace it with 120D / 24F ordinary polyester multifilament to continue weaving The main fabric with a length of 34 cm is finally replaced with high-density high-elasticity polyester multifilament to weave the anti-spray side sealing structure 4 at the other end. The fabric structure is plain weave;

[0039] The second step: at room temperature, the prepared integrally formed fabric reinforcement la was successively placed in an ultrasonic cleaner equipped with detergent and clear water for 1 hour, and then spread it flat in an oven and dried at 40°C for 2 hours;

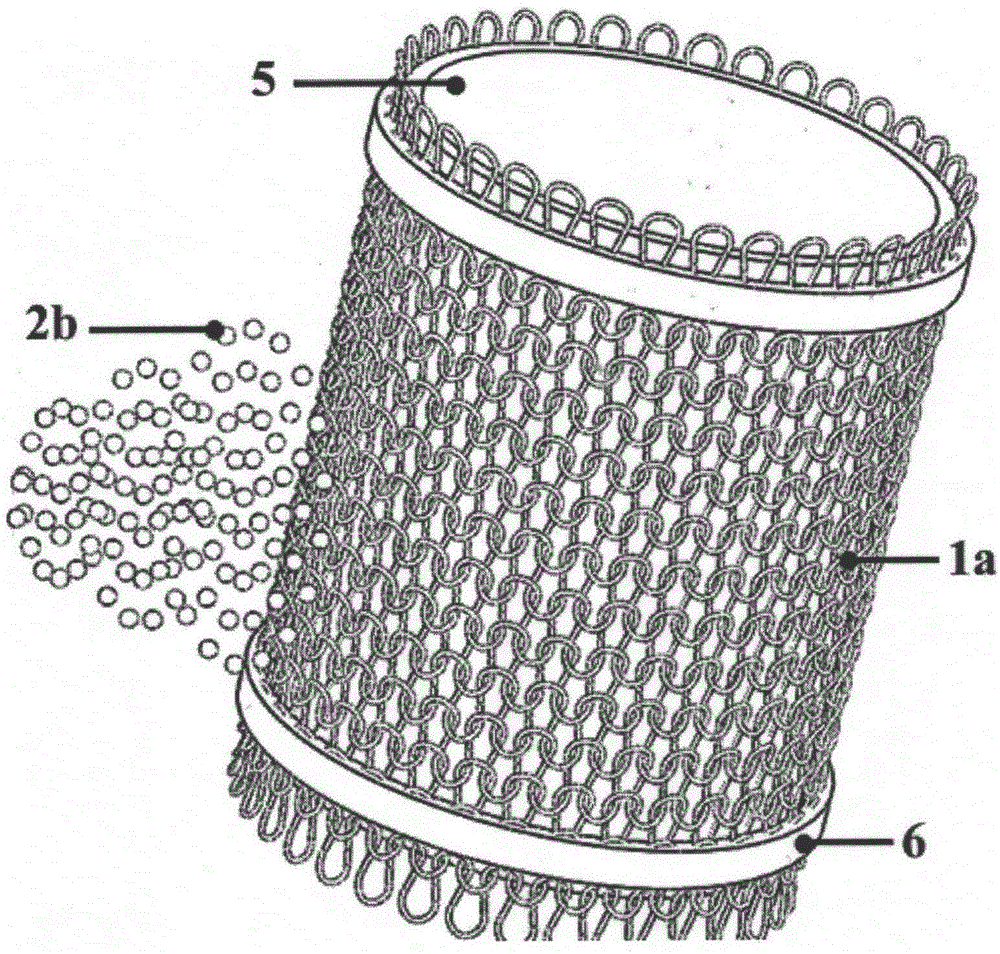

[0040] Step 3: Insert the dried integrally formed fabric reinforcement 1a into a mold tube 5 with a perimeter of 350m...

Embodiment 2

[0045] A preparation method of precision seamless textile base flat belt:

[0046] Step 1: Use 240D / 24F high linear density and high elasticity polyester multifilament to weave one end anti-spray edge sealing structure 4 on a custom-made circular knitting machine, the length of which is 5m, and then replace it with 150D / 24F ordinary polyester multifilament to continue weaving The main fabric with a length of 30 cm is finally replaced with high-density high-elasticity polyester multifilament to weave the other end of the anti-scattering edge sealing structure 4. The fabric structure is rib weave;

[0047] Step 2: at room temperature, place the obtained integrated fabric reinforcement 1a in an ultrasonic cleaner filled with detergent and clean water for 2 hours, and then lay it flat in an oven and dry it at 60°C for 4 hours;

[0048] Step 3: Put the dried integrally formed fabric reinforcement 1a into the mold tube 5 with a circumference of 200mm, fix one end on the mold tube 5 w...

Embodiment 3

[0053] A preparation method of precision seamless textile base flat belt:

[0054] Step 1: Use 210D / 24F high linear density and high elasticity nylon multifilament to weave one end anti-spray edge sealing structure 4 on a custom-made circular knitting machine, the length of which is 15cm, and then replace it with 80D / 24F ordinary nylon multifilament to continue weaving The main fabric with a length of 41 cm is finally replaced with high-density high-elastic nylon multifilament to weave the other end of the anti-scattering edge sealing structure 4. The fabric structure is weft flat stitch;

[0055] Step 2: at room temperature, place the obtained integrated fabric reinforcement 1a in an ultrasonic cleaner filled with detergent and clean water for 1.5 hours, and then lay it flat in an oven and dry it at 50°C for 5 hours;

[0056] Step 3: Insert the dried integrated fabric reinforcement 1a into the mold tube 5 with a circumference of 500mm, fix one end on the mold tube 5 with a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending stiffness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com