Large-scale machining method for aluminum alloy empennages

A processing method and aluminum alloy technology, applied in the field of fin processing, can solve the problems of low material utilization rate, low processing efficiency and high processing cost, and achieve the effects of improving processing efficiency, reducing manufacturing cost and improving material utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A mass processing method of aluminum alloy tail wing of the present invention, the specific processing method is as follows:

[0026] 1) Heat the aluminum alloy blank and mold uniformly to 480±5°C in an electric furnace, and keep it warm for two hours;

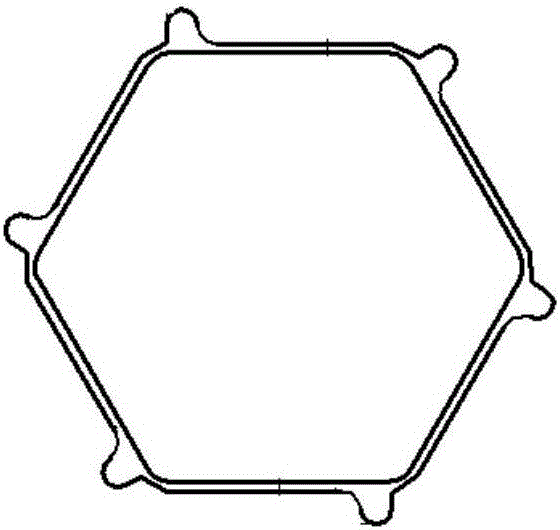

[0027] 2) The aluminum alloy blank is extruded into a tail wing profile through an extrusion die, and its structure is as figure 1 , 2 As shown, the empennage profile is an equilateral hexagonal cylindrical structure with open ends. The length of the prismatic cylinder matches twice the length of the empennage product. The inner shape of each quadrilateral side wall of the prismatic cylinder is the same as that of the empennage product. Match the shape of the inner and outer panels;

[0028] 3) Take the extruded tail wing profile out of the mold, keep it at 497±3℃ for 60min, and then place it under water cooling at 40℃ for 120 hours.

[0029] 4) Cut the tail wing profile into two blanks with a length matching the length of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com